Laser scribing device for shearing copper plate

A laser scribing and copper plate technology, which is applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of not being able to cut, bolts not being too tight, and copper plates not being centered, so as to prevent deflection and ensure continuous performance, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

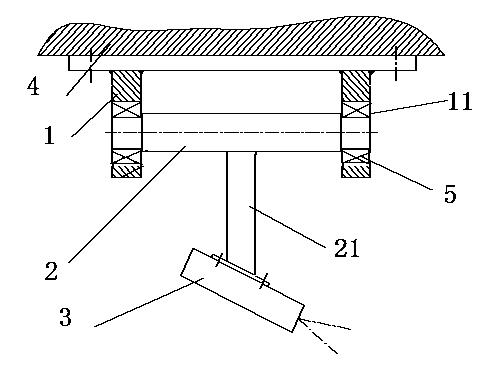

[0011] A laser scribing device for copper plate shearing, including a support 1, a swing shaft 2 and a laser scribing transmitter 3, the support is fixed on a frame 4, and mounting holes 11 are provided on the supports on both sides, The mounting holes on the supports on both sides are circular, and the centers of the two mounting holes are on the same straight line; the concentricity of the two mounting holes is guaranteed. The swing shaft is a T-shaped structure, wherein one side of the T shape is the rotating shaft, and the I side of the T shape is the mounting handle 21; the two ends of the rotating shaft are provided with mounting shafts, and the mounting shafts are installed in the mounting holes through the bearings 5; The device is set at the end of the mounting handle. The laser scribing emitter is set on the mounting handle through bolts. There are dust covers on the outside of the support, swing shaft and laser marking transmitter.

[0012] When installing, first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com