Rectangular frame welding device

A welding device and a rectangular frame technology, applied in the field of fixtures, can solve the problems of no adjustment mechanism, the inability to improve welding accuracy, and the dimensional accuracy of workpieces, and achieve the effects of improving welding quality, improving pass rate, and improving dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention is described below in conjunction with accompanying drawing.

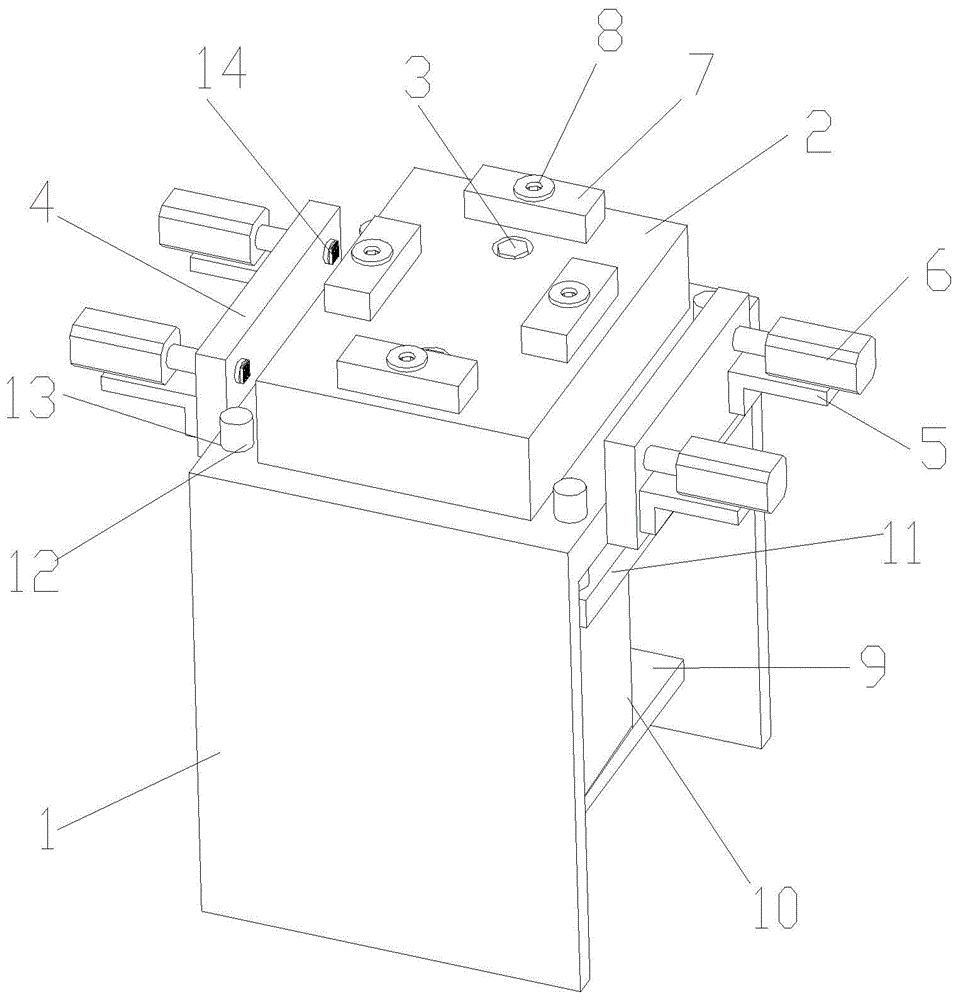

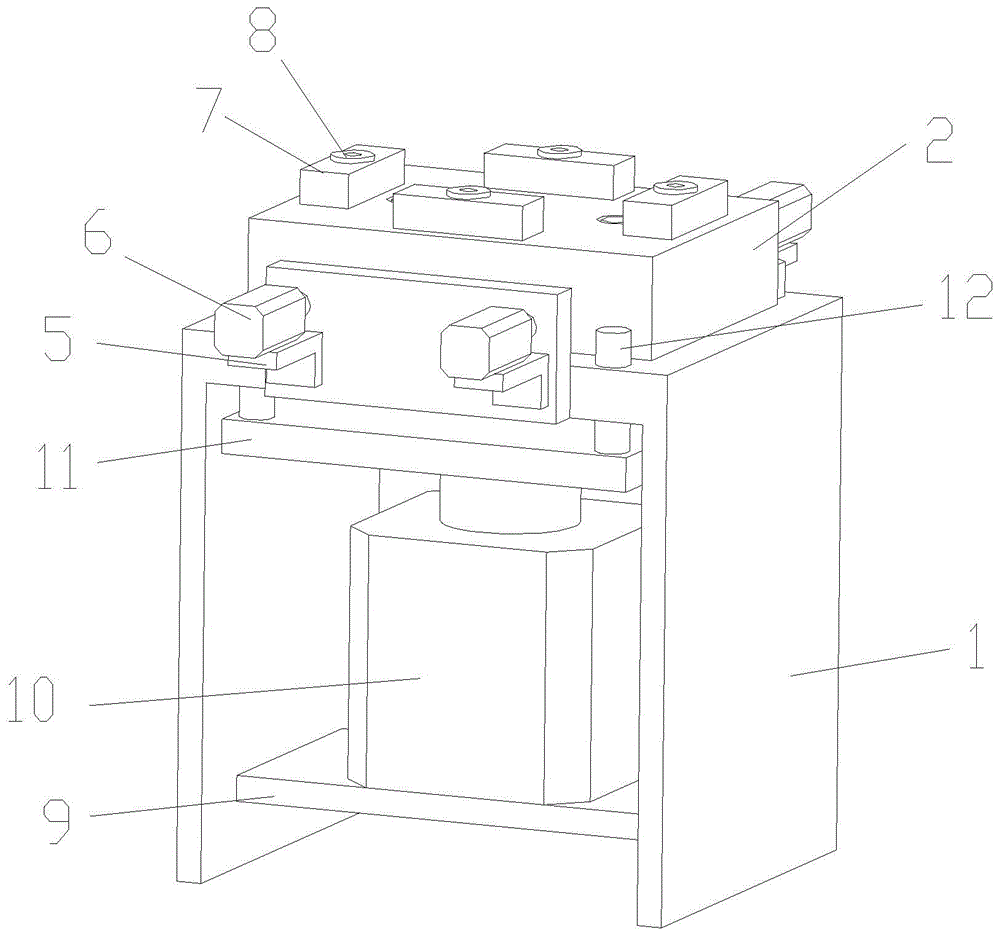

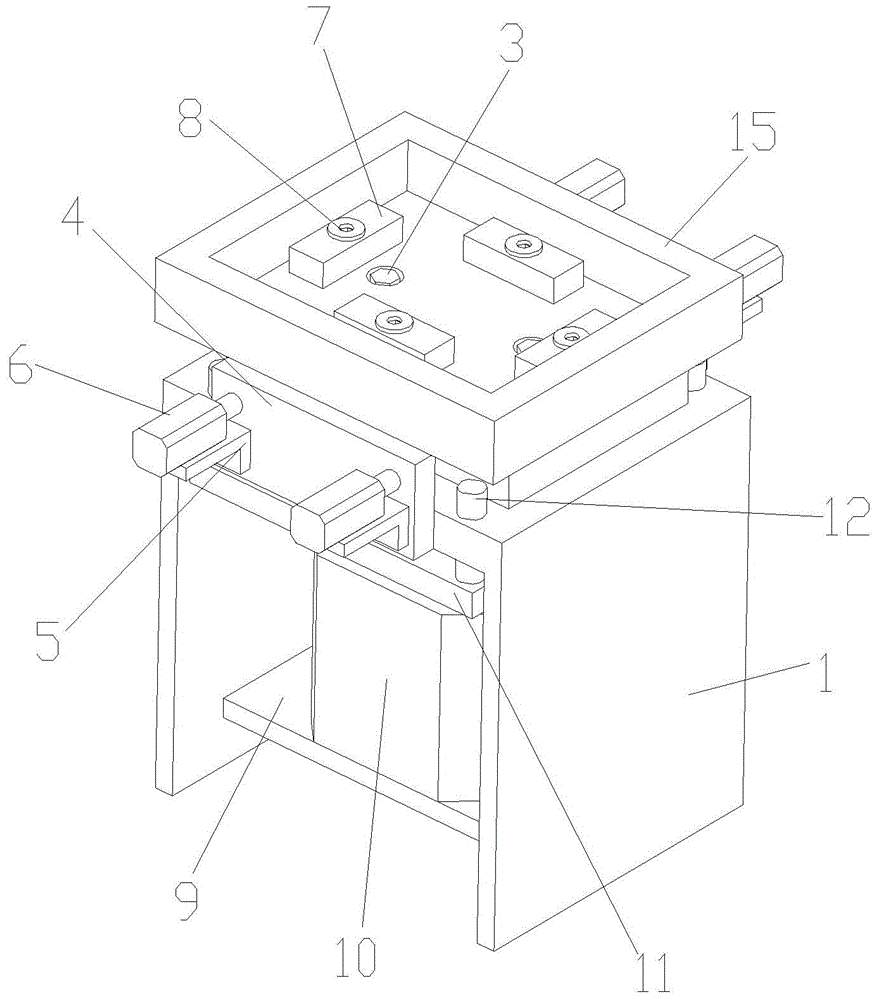

[0016] as attached Figure 1-3 Shown is a rectangular frame welding device according to the present invention, including a support frame 1 and a rectangular seat 2; the rectangular seat 2 is fixedly arranged on the table top of the support frame 1 by connecting bolts 3; the table top of the support frame 1 Both sides are respectively fixed with fixed baffles 4, the rectangular seat 2 is smaller than the table top, and a section of the table top exposes the rectangular seat 2, so that it forms a sandwich with the fixed baffle 4 for placing products 15; the fixed baffle 4 passes through The L-shaped connection block 5 is fixedly provided with two jacking cylinders 6; the piston ends of the jacking cylinders 6 extend toward the rectangular seat 2, and the piston ends of the jacking cylinders 6 are also provided with locking teeth 14 for pushing the product 15 Fine-tune the product 15 tigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com