Polishing Die Surface Shape Modifying Device

A technology for modifying devices and polishing molds, which is applied in the direction of optical surface grinders, grinding/polishing equipment, grinding machines, etc., can solve the problems of uneven pressure, application, and low efficiency of polishing mold surface shapes, and reduce uncertain factors and improve The efficiency of processing, the effect of improving processing quality and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with embodiment the present invention is further described.

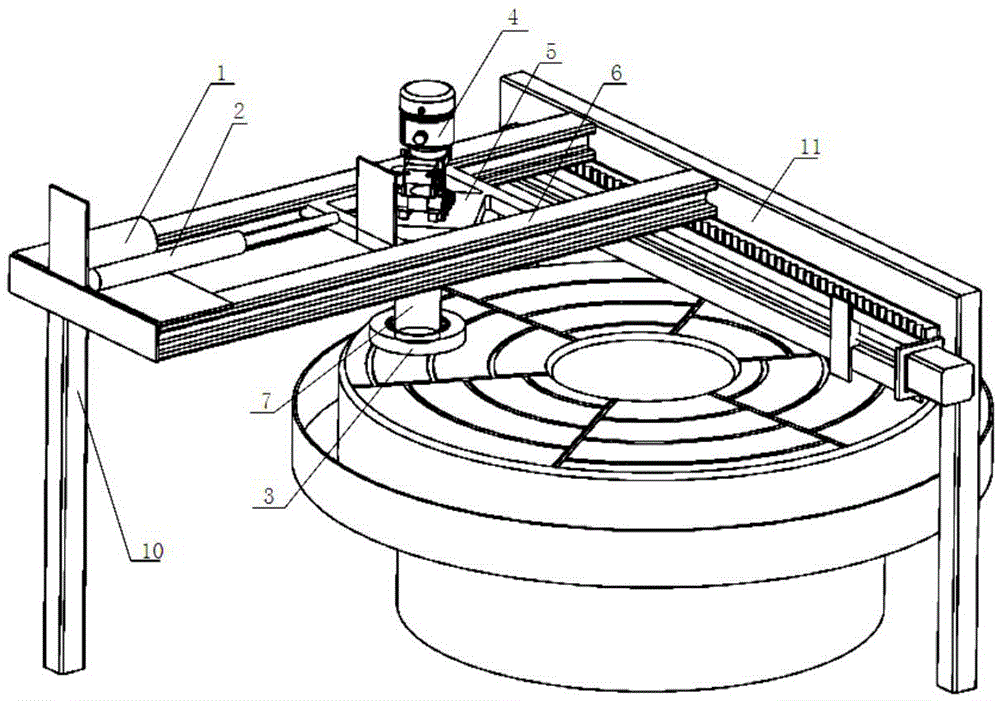

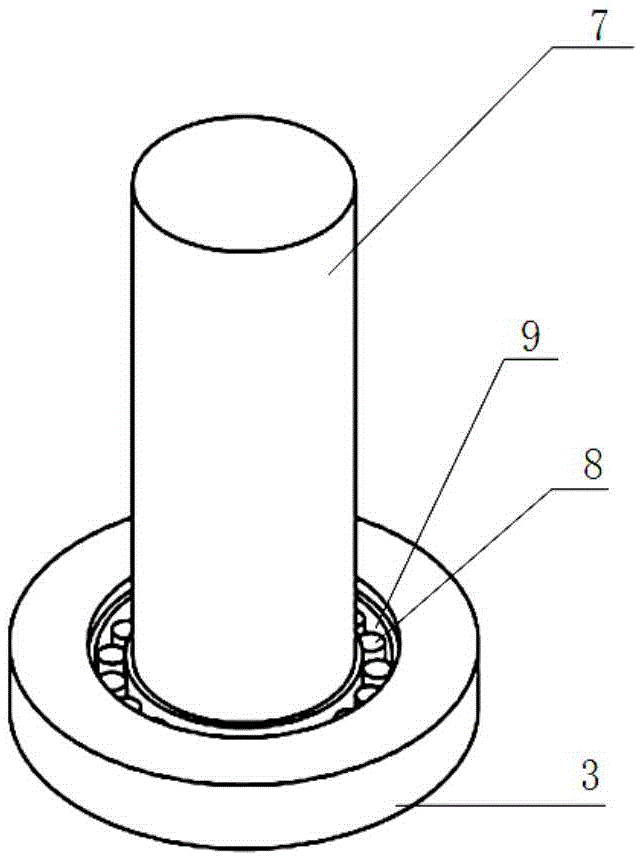

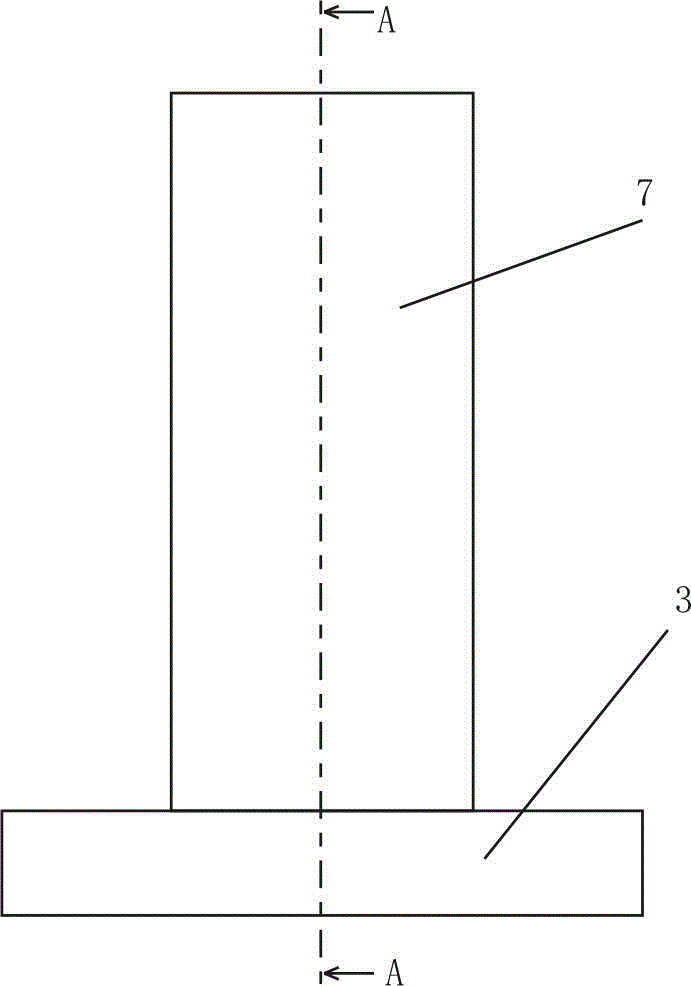

[0016] see figure 1 —4, polishing die surface shape modifying device, comprises support column 10, support frame 11, guide rail 6 and driving motor 1, and guide rail 6 two ends are supported by support column 10 and support frame 11 and are connected with it; Also comprise translation device 5, apply The pressing device 4 and the modification disk 3; the translation device 5 is fixed on the guide rail 6 by the chute, and the translation device 5 is driven by the drive motor 1; a limit rod 2 is arranged between the translation device 5 and the supporting column 10; the pressing device 4 is translated The device 5 is connected with the guide rail 6, and the lower part of the pressure applying device 4 is connected with the modification disk 3 through the pressure transmission rod 7, and a levelness adjustment device is arranged between the modification disk 3 and the pressure transmission r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com