Water absorption appliance with variable pipe diameter

A device and variable technology, applied in the direction of pipes, pipe components, rigid pipes, etc., can solve the problems of poor interface adaptability, etc., and achieve the effects of high assembly efficiency, tight combination, and increased pipe wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

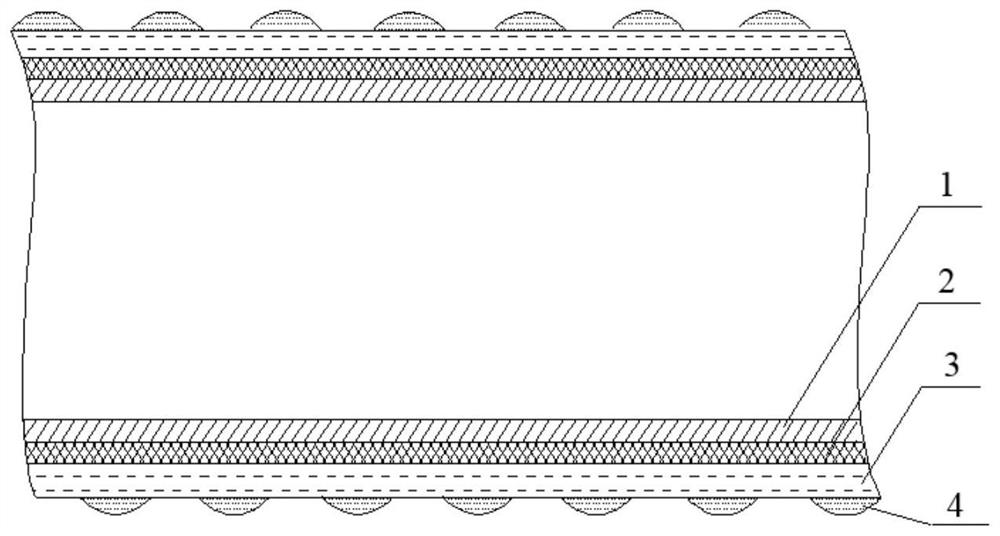

[0025] A water-absorbing device with variable pipe diameter is a spiral water-absorbing pipe whose structure from inside to outside is as follows: figure 1 As shown, it includes an inner rubber layer 1 , a pressure sensitive adhesive layer 2 , an outer rubber layer 3 and a spiral rib layer 4 from inside to outside in sequence.

[0026] Wherein, the inner rubber layer is made of soft PVC-based material or thermoplastic polyurethane material, with a thickness of 1.5-2.5 mm and a Shore A hardness of 25-30.

[0027] Wherein, the material of the outer rubber layer and the spiral rib layer is a rigid PVC-based material; the thickness of the outer rubber layer is 4-6mm, and the Shore A hardness is 35-40; Shore hardness A is 85-90.

[0028] Wherein, the material of the pressure-sensitive adhesive layer is a thermoplastic elastomer-based material, including the following raw materials in parts by weight: 100 parts of SIS, 20 parts of tetraacicular nano-zinc oxide, 50 parts of nano-ult...

Embodiment 2

[0033] A water-absorbing device with variable pipe diameter is a spiral water-absorbing pipe whose structure is the same as that of Embodiment 1.

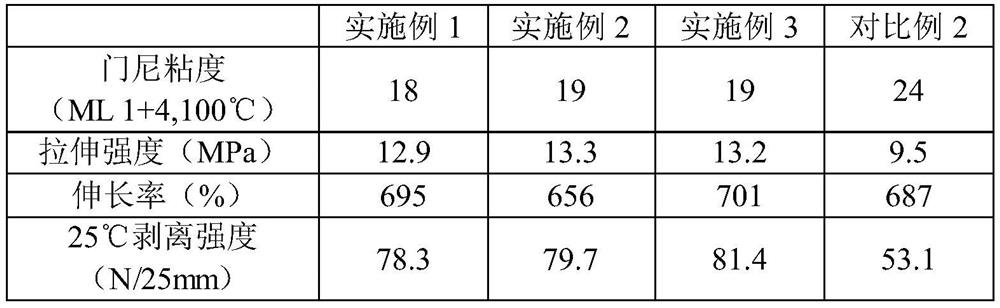

[0034] The difference is that, wherein, the material of the pressure-sensitive adhesive layer is a thermoplastic elastomer-based material, including the following raw materials in parts by weight: 100 parts of SBS, 30 parts of tetraacicular nano-zinc oxide, 40 parts of nano-ultrafine clay, o-phthalic Dioctyl dicarboxylate 5 parts, terpene phenolic resin 10 parts, C5 petroleum resin 5 parts, coumarone resin 10 parts, PX antioxidant 1 part, Antiozaid L122 antioxidant 1 part. Thickness 2.5 ~ 3.5mm. The basic properties of the pressure-sensitive adhesive layer in this embodiment are shown in Table 1.

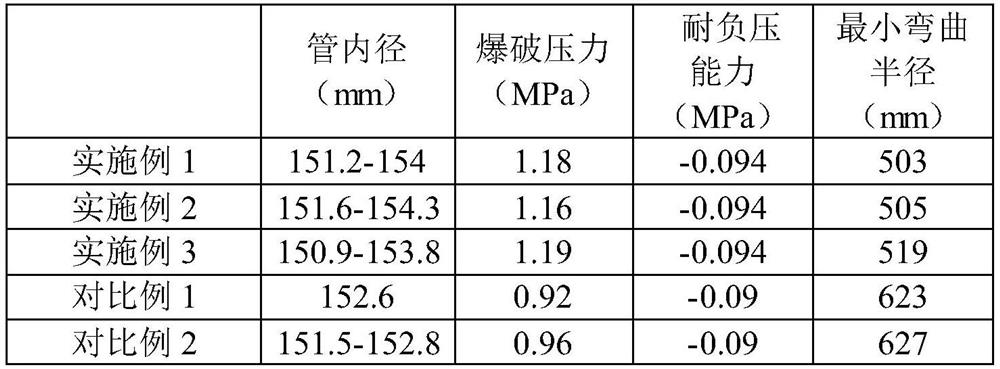

[0035] The overall performance of the spiral water suction pipe of this embodiment is shown in Table 2.

Embodiment 3

[0037] A water-absorbing device with variable pipe diameter is a spiral water-absorbing pipe whose structure is the same as that of Embodiment 1.

[0038] The difference is that, wherein, the material of the pressure-sensitive adhesive layer is a thermoplastic elastomer-based material, including the following raw materials in parts by weight: 50 parts of SBS, 50 parts of SIS, 40 parts of tetraacicular nano-zinc oxide, 30 parts of nano-ultrafine kaolin 5 parts, 5 parts of dioctyl terephthalate, 10 parts of terpene resin, 10 parts of C9 aromatic petroleum resin, 1 part of BZ antioxidant, 1 part of Antiozaid L122 antioxidant. Thickness 2.5 ~ 3.5mm. The basic properties of the pressure-sensitive adhesive layer in this embodiment are shown in Table 1.

[0039] The overall performance of the spiral water suction pipe of this embodiment is shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| Shore hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com