Sanding belt-sanding disc machine

The technology of sand disc machine and abrasive belt is applied in the direction of abrasive belt grinder, grinder, metal processing equipment, etc. It can solve the problems of inconvenient installation and maintenance, troublesome belt disassembly, complex structure, etc., and achieve reliable performance, convenient use and maintenance, and excellent structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

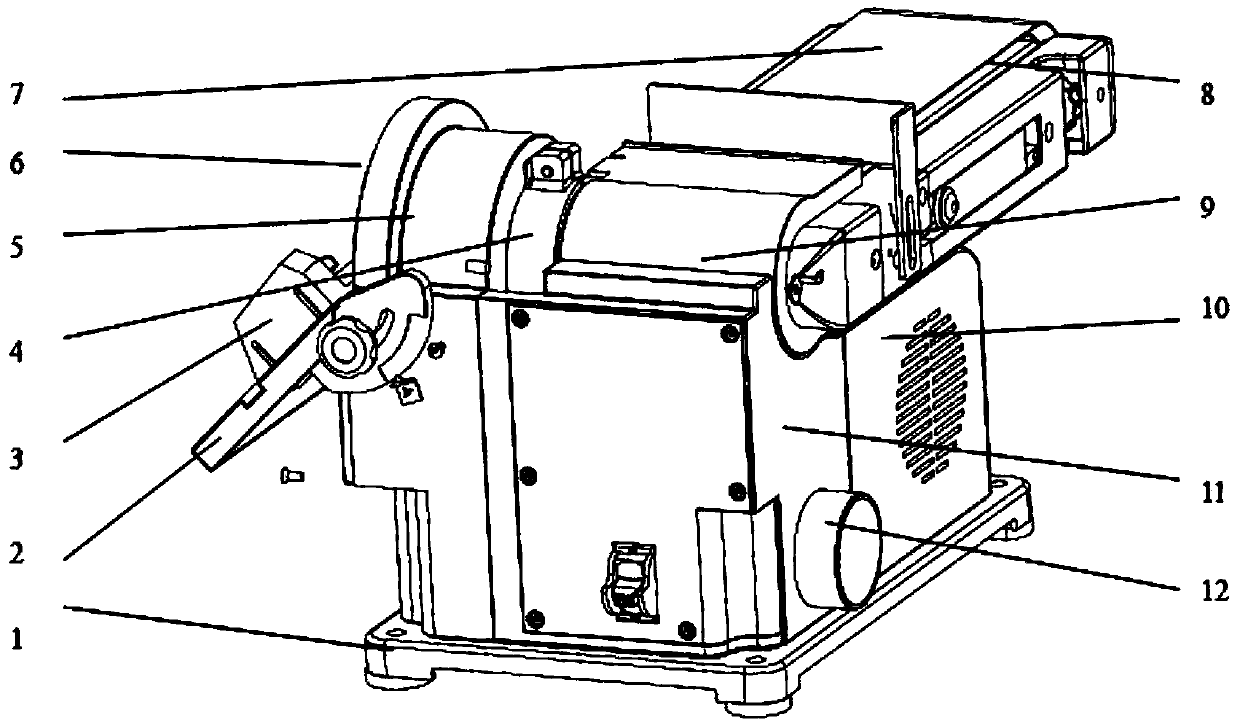

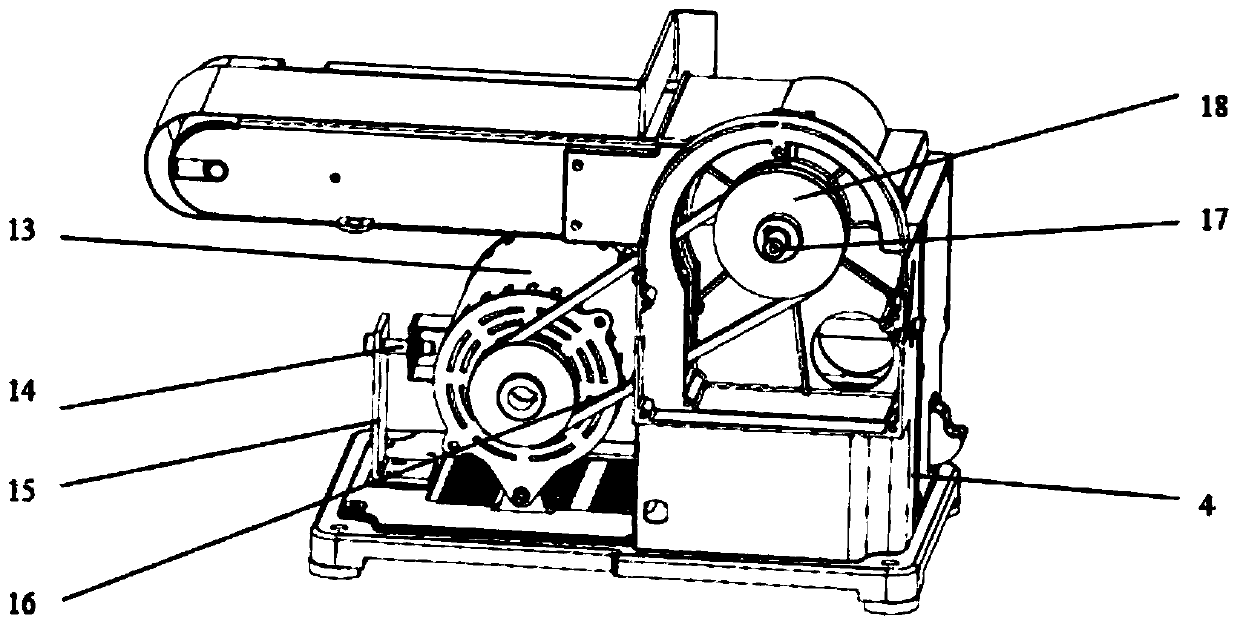

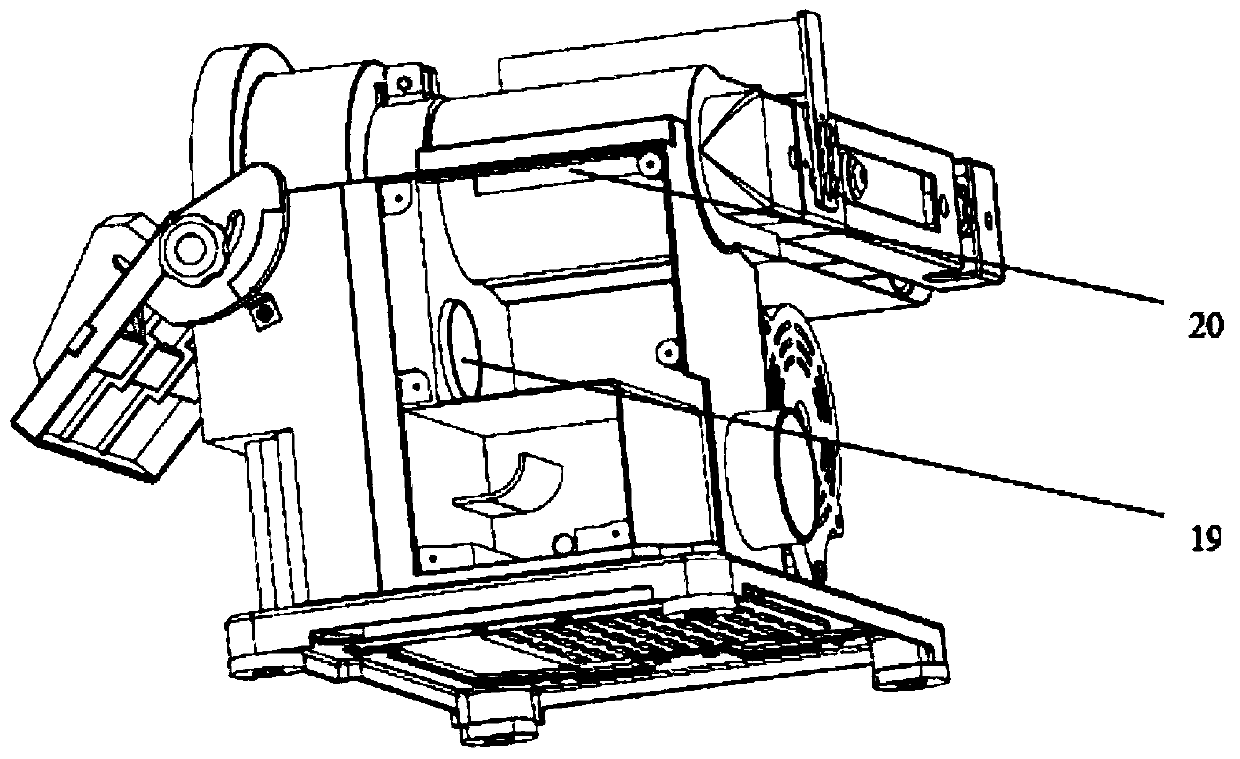

[0013] Depend on figure 1 , 2 , 3, 4, 5, and 6, a belt sander, comprising a base 1, a support 5, a motor 13, a belt tensioning support 15, an abrasive belt 7, a sand disc 6, a workbench 2, and The table 2 is tightly connected with the support 5 on the outside of the sand disc 6, and the support 5 is installed on the base 1. There is a rotating shaft 17 on the upper part of the supporting seat 5, and a belt pulley 18 is installed on the rotating shaft 17, and one end of the end shaft of the belt pulley 18 is installed. Sand disc 6 is arranged, and the bearing 5 of sand disc 6 bottoms is provided with sand disc suction mouth 19, and the other end of pulley 18 end axles is equipped with abrasive belt driving drum, and the abrasive belt driving drum is at one end of abrasive belt support 8, and the abrasive belt driving drum is The belt bracket 8 is connected with the bracket connecting plate 4 provided on the support 5, and the end of the abrasive belt bracket 8 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com