An aero-engine outfield motor installation platform

An aero-engine and installation platform technology, applied in hand-held tools, manufacturing tools, etc., can solve problems such as low work efficiency, poor safety, and large generator volume, so as to improve work efficiency, reduce labor intensity, and avoid work-related accidents Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

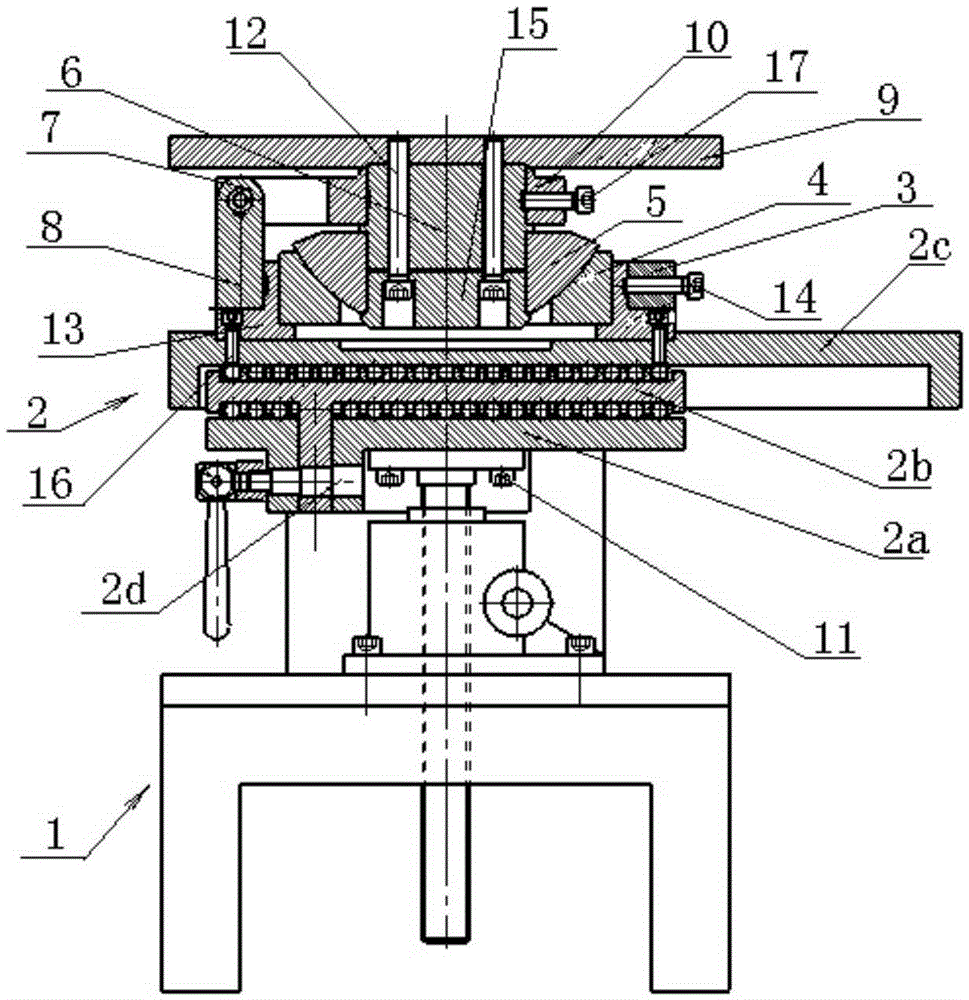

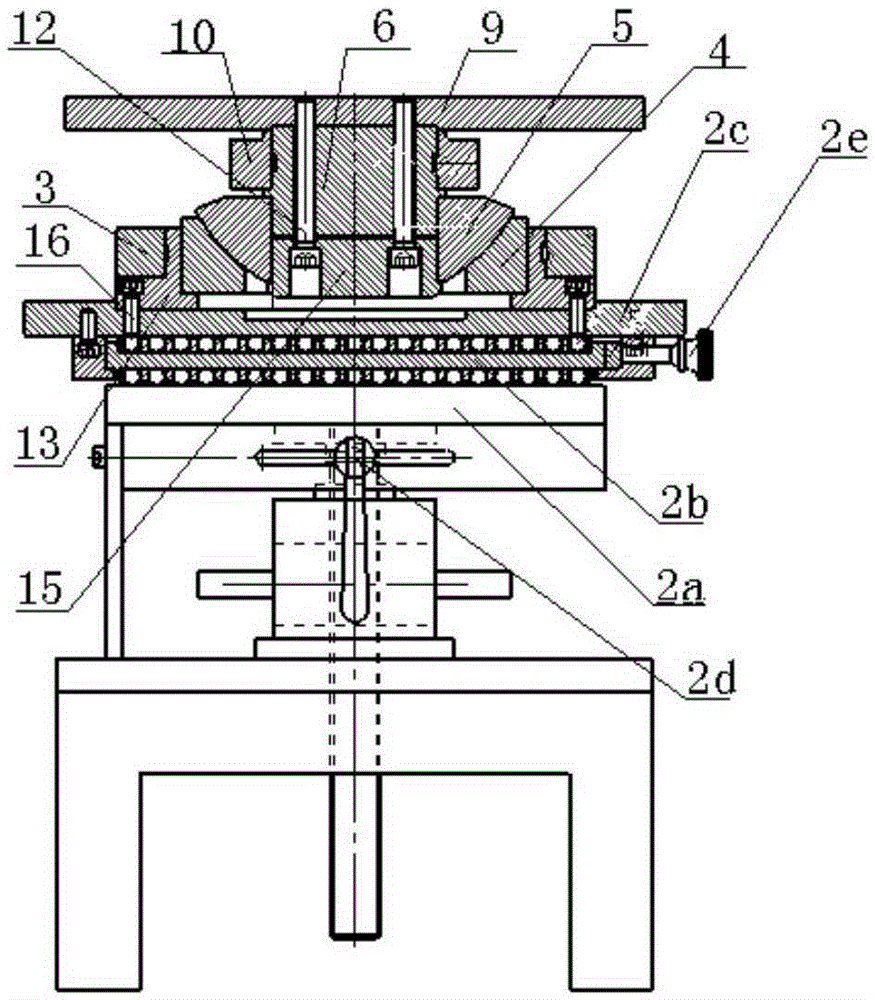

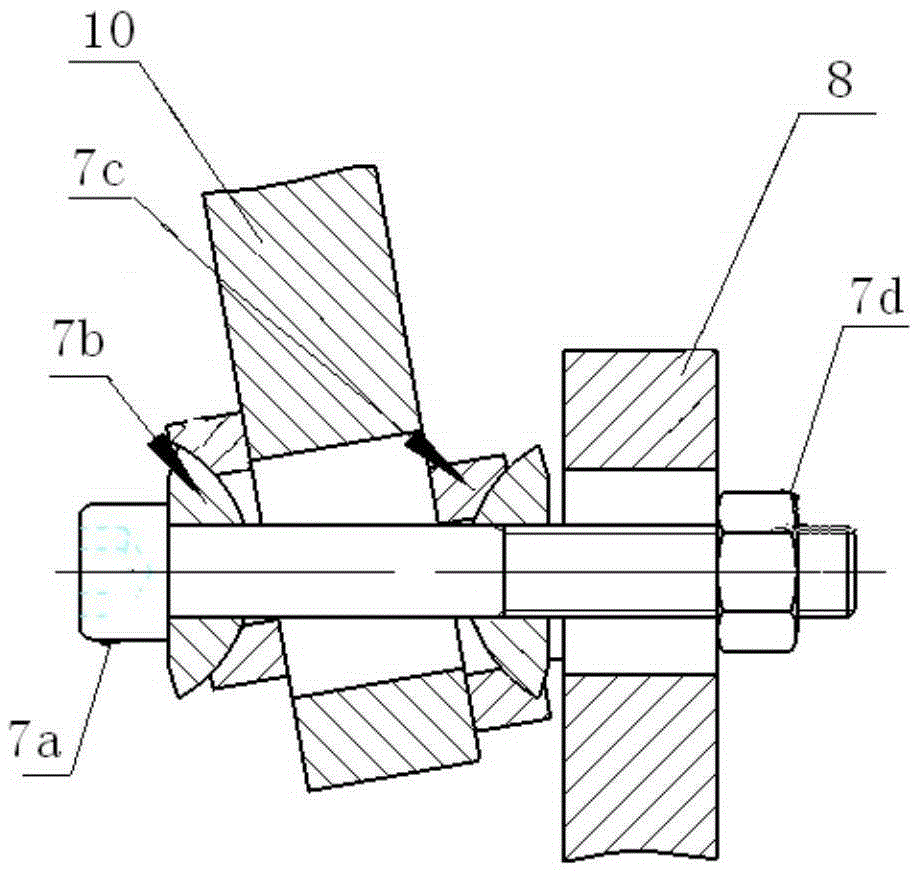

[0009] The present invention will be described in further detail below. see Figure 1 to Figure 3 , an aero-engine outfield motor installation platform is characterized in that: it is composed of a base 1, a two-dimensional linear movement mechanism 2 and a universal rotation mechanism; the base 1 is equipped with a turbine and worm height adjustment mechanism; The bottom plate 2a is fixed on the liftable workbench of the worm screw height adjustment mechanism of the base 1 through the bottom plate fixing screws 11. There is a forward and backward moving sliding plate locking mechanism 2d between the forward and backward moving sliding plate 2b, and the left and right moving sliding plate 2c of the two-dimensional linear moving mechanism 2 is located on the front and rear moving sliding plate 2b. Sliding plate locking mechanism 2e; the universal rotation mechanism is composed of lower locking ring 3, joint bearing, upper shaft 6, mounting plate locking assembly 7, bracket 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com