Production process of a puncture-resistant tire

A production process and tire technology, which is applied in the field of production process of puncture-resistant tires, can solve the problems of low production efficiency and high cost, and achieve the effects of high production efficiency, low cost and maintaining airtight performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

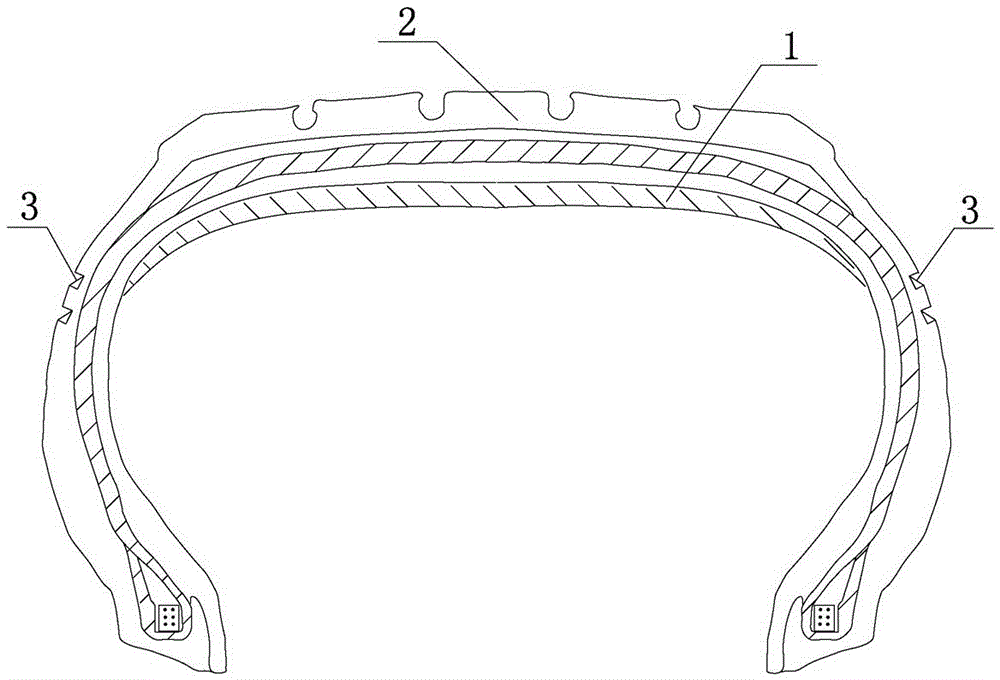

[0032] refer to figure 1 , a production process of anti-puncture tires, comprising the steps of:

[0033] (1) The adhesive is prepared by spraying and shaping to obtain the self-sealing layer film 1; wherein, the adhesive is a combination of polyurethane and EVA hot-melt adhesive, wherein the weight ratio of polyurethane to hot-melt adhesive is 1:0.45, and the self-sealing layer film Forming by spraying and cooling;

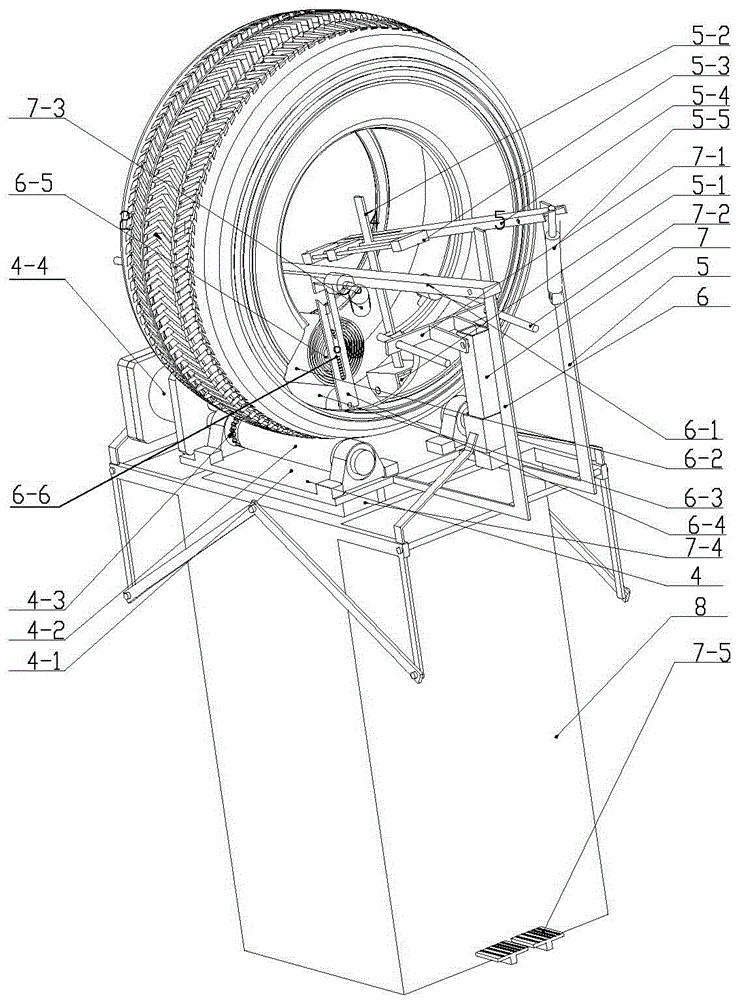

[0034] (2) After cleaning the inner surface of the carcass 2, an adhesive is sprayed on the inner surface of the carcass. Pressurize and shape to get the puncture-proof tire; wherein, the lamination between the self-sealing layer film and the inner surface of the carcass is completed by a placement machine, the thickness of the self-sealing layer film 1 is 2.3mm, and the coverage of the self-sealing layer film is the tire tire The whole crown extends to the tire anti-friction line 3 toward the shoulder direction; the adhesive includes the following components: mo...

Embodiment 2

[0052] refer to figure 1 , a production process of anti-puncture tires, comprising the steps of:

[0053] (1) The adhesive is prepared by spraying and shaping to obtain the self-sealing layer film 1; wherein, the adhesive is a combination of polyurethane, polyacrylic resin and polyamide, and the weight ratio of polyurethane, polyacrylic resin and polyamide is 1:0.85 : 0.15;

[0054] (2) After cleaning the inner surface of the carcass 2, an adhesive is sprayed on the inner surface of the carcass. The puncture-resistant tire is obtained by pressurizing and shaping; wherein, the self-sealing layer film and the inner surface of the carcass are bonded by a cold paste process, the thickness of the self-sealing layer film 1 is 2.1mm, and the self-sealing layer film covers the entire crown of the tire. And extend to tire antifriction line 3 toward tire shoulder direction; Described binding agent comprises following component: modified alicyclic amine epoxy resin curing agent, silane...

Embodiment 3

[0056] A kind of production technology of anti-puncture tire, comprises the steps:

[0057] (1) The self-sealing layer film is prepared by spraying and shaping the polyurethane adhesive; the self-sealing layer film is formed by spraying and heating;

[0058] (2) After cleaning the inner surface of the carcass, spray the adhesive on the inner surface of the carcass, after the self-sealing layer film and the inner surface of the carcass are bonded and pasted by adhesive, and then pressurized and shaped. Anti-puncture tire; wherein, the lamination process between the self-sealing layer film and the inner surface of the carcass is completed by the placement machine described in Embodiment 1, the thickness of the self-sealing layer film is 2.7mm, and the coverage of the self-sealing layer film is tire tire The whole crown extends to the tire anti-friction line in the direction of the shoulder; the adhesive includes the following components: modified alicyclic amine epoxy resin curi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com