Passenger car braking pipeline system for cold region

A cold area, brake pipe technology, applied in the direction of brakes, brake components, brake transmission devices, etc., can solve the hidden safety hazards in the brake pipeline, affect the function of each valve and the smoothness of the gas path, and endanger the safety of the whole vehicle and other problems to achieve the effect of improving braking safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing:

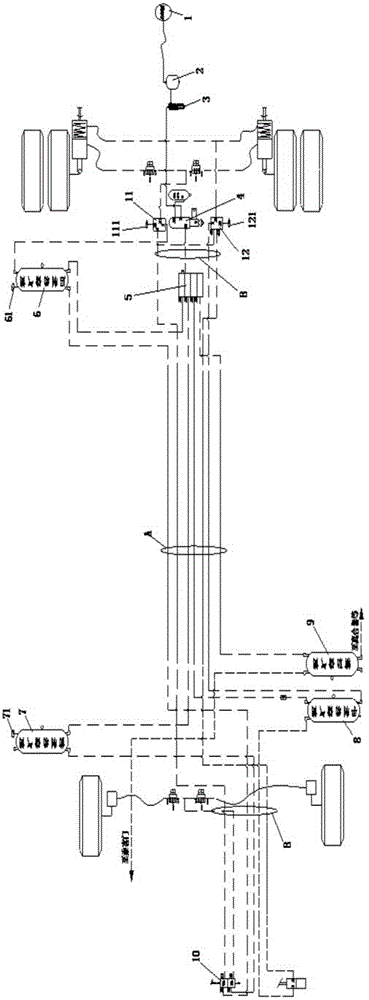

[0015] Such as figure 1 Shown 1. A passenger car brake pipeline system used in cold regions, including an air compressor 1, a dehumidification air storage tank 2, a condenser 3, a dryer 4 and a four-circuit valve 5, which are connected in sequence through pipelines. The model of the circuit valve 5 is WABCO9347140100, where WABCO is the name of the manufacturer, and the following 9347140100 is the specific model (the valves appearing in the following are the same), the outlet of the dryer 4 is connected to the port 1 of the four-circuit valve 5, and the four-circuit valve 5 Ports 21, 22, 23 and 24 are respectively connected to the rear brake air storage cylinder 6, front brake pipeline system, front brake pipeline system, hand brake pipeline system and auxiliary air system. The moving air storage cylinder 7, the hand brake air storage cylinder 8, and the auxiliary air stor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com