Tire mounting structure and application method thereof

A technology for installing structures and tires, which is applied in tire installation, tire parts, transportation and packaging, etc. It can solve problems such as tire drop, large size and weight, and increase the working load of the telescopic end of lifting equipment, so as to increase the moving speed , reduce the workload, facilitate the rapid rise of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

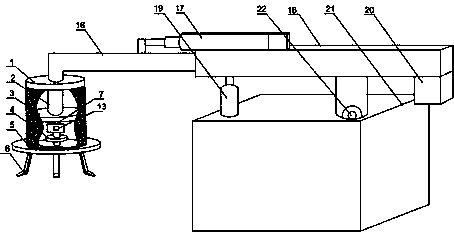

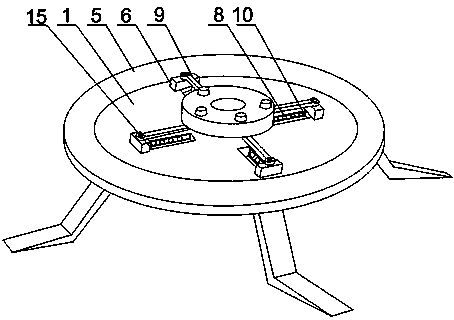

[0023] Such as Figure 1 to Figure 3 As shown, the present invention is a tire mounting structure and its use method. Put the claw 6 at the lower end of the supporting cylinder 1 into the inner ring of the tire, start the motor 2, and the output end of the motor 2 rotates to drive the turntable 4 to start rotating. The jaws 6 are hinged to the bottom of the turntable 4 through the connecting rod 9, and the connecting rod 9 drives the jaws 6 to slide freely in the horizontal groove 15. When the diameter of the jaw ring formed by a plurality of jaws 6 gradually increases, the jaws 6 Closely attached to the inner ring of the tire, and then realize the clamping and fixing of the tire; during the process of clamping the tire by the claw 6, the claw 6 is pushed to the outermost end of the horizontal groove 15 by the connecting rod 9, and the direction of the connecting rod 9 is just right Vertical to the axis direction of the turntable 4, the jaws 6 are in a self-locking state at th...

Embodiment 2

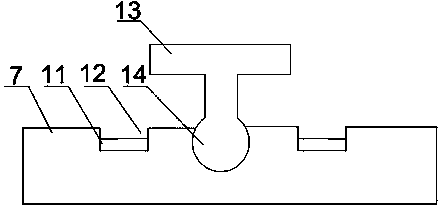

[0025] Such as image 3As shown, in this embodiment, on the basis of Embodiment 1, the limiting structure includes a limiting plate 7, the limiting plate 7 is fixed on the baffle plate 3, and a through hole is opened in the middle of the limiting plate 7, Described motor output end 14 passes through hole, has two grooves 12 on the same side of limiting plate 7, and two grooves 12 are positioned at the both sides of motor 2 output ends, is installed on motor output end 14 T-shaped block 13, travel switch 11 is installed in the groove 12, and travel switch 11 is connected with motor 2 by lead. When clamping the tire placed horizontally, the motor 2 rotates, driving the T-shaped block 13 on the motor output end 14 to rotate, and when the claw 6 slides to the outermost end of the horizontal groove 15, one end of the T-shaped block 13 Contact with the travel switch 11 in the groove 12, the travel switch 11 controls the motor 2 to stop rotating; The travel switch 11 in the groove ...

Embodiment 3

[0027] Such as figure 1 As shown, this embodiment is based on Embodiment 1. The telescopic structure includes a boom 18 and a telescopic boom 16. The boom 18 is arranged on the base 21 through a rotating shaft 22. The boom 18 is provided with a chute and a first Hydraulic cylinder 17, the output end of the first hydraulic cylinder 17 is connected with the middle part of the telescopic arm 16, one end of the telescopic arm 16 is slidably arranged in the chute, and the other end of the telescopic arm 16 is connected with the support cylinder 1; The cylinder 19 and the second hydraulic cylinder 19 are installed on the base 21 , and the output end of the second hydraulic cylinder 19 is connected with the bottom of the boom 18 . When starting to install the tire, start the first hydraulic cylinder 17, the first hydraulic cylinder 17 pushes the telescopic arm 16 to move previously, and the supporting cylinder 1 connected with the telescopic arm 16 moves accordingly, and the supporti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com