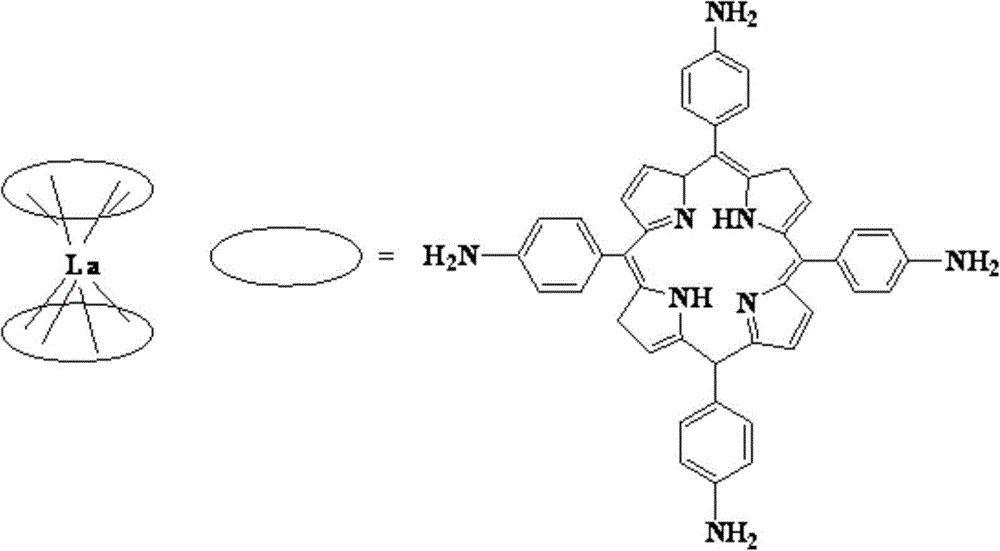

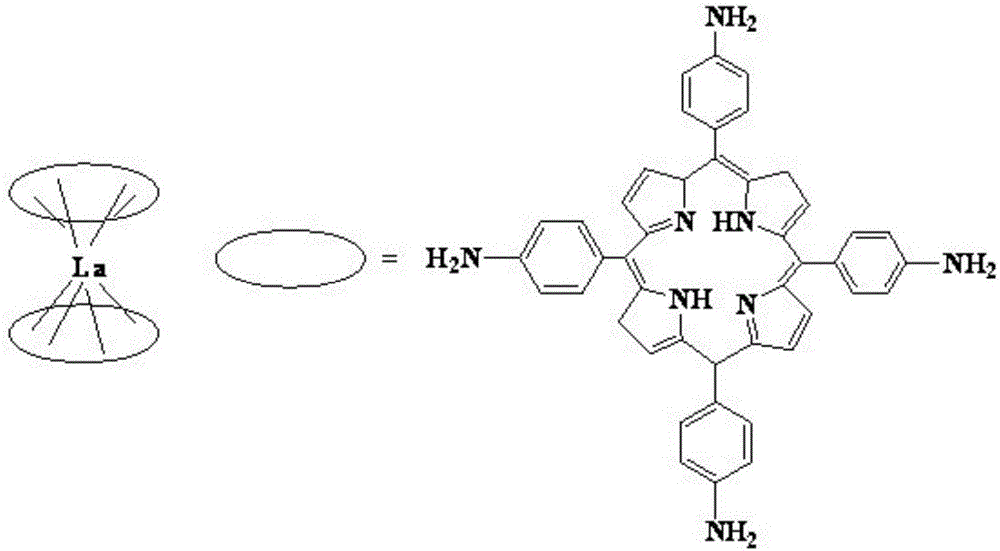

A water-soluble double-layer sandwich-type la metalloporphyrin complex and its application in microcontact printing technology

A micro-contact printing, sandwich-type technology, applied in the field of modern electronics, can solve problems such as applications that have not been reported, and achieve the effects of easy availability of raw materials, low cost and high resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) Substrate surface treatment: Soak the polymer substrate in 45% isopropanol aqueous solution for 30 minutes, then soak it in 2mol / L sulfuric acid at 55°C for 15 minutes, then wash it with water, dry it in vacuum at 60°C, and put it on the polymer substrate Carboxyl groups are introduced into the surface to obtain carboxylated substrates;

[0029] 2) Prepare an aqueous solution of bis(5,10,15,20-tetra-p-aminophenylporphyrin) with La: dissolve bis(5,10,15,20-tetra-p-aminophenylporphyrin) with La in water, Obtaining a concentration of 2g / L bis(5,10,15,20-tetra-p-aminophenylporphyrin) La aqueous solution;

[0030] 3) Microcontact printing: Soak the PDMS stamp in di(5,10,15,20-tetra-p-aminophenylporphyrin) and La aqueous solution for 30s, take it out and put it in N 2 Dry in airflow for 30s, put the PDMS stamp coated with bis(5,10,15,20-tetra-p-aminophenylporphyrin) La aqueous solution on the carboxylated substrate, press lightly for 10s, and transfer the PDMS stamp patte...

Embodiment 2

[0034] 1) Substrate surface treatment: Soak the polymer substrate in 55% isopropanol aqueous solution for 60 minutes, then soak it in 3mol / L sulfuric acid at 65°C for 20 minutes, then wash it with water, dry it in vacuum at 65°C, and place it on the polymer substrate Carboxyl groups are introduced into the surface to obtain carboxylated substrates;

[0035] 2) Prepare an aqueous solution of bis(5,10,15,20-tetra-p-aminophenylporphyrin) with La: dissolve bis(5,10,15,20-tetra-p-aminophenylporphyrin) with La in water, Obtaining a concentration of 5g / L bis(5,10,15,20-tetra-p-aminophenylporphyrin) La aqueous solution;

[0036] 3) Microcontact printing: Soak the PDMS stamp in di(5,10,15,20-tetra-p-aminophenylporphyrin) and La aqueous solution for 40s, take it out and put it in N 2 Dry in airflow for 60s, cover the PDMS stamp coated with bis(5,10,15,20-tetra-p-aminophenylporphyrin) La aqueous solution on the carboxylated substrate, press lightly for 20s, and transfer the PDMS stamp p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com