Tertiary air duct high temperature wear-resistant valve plate

A high-temperature wear-resistant, valve plate technology, used in sliding valves, valve devices, engine components, etc., can solve the loss of air volume in the kiln and the balance of air volume in the furnace, the negative impact of system stability, and the tertiary air duct valve plate. Short life and other problems, to achieve excellent spalling resistance and cracking resistance, convenient construction, and improve the effect of difficult processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

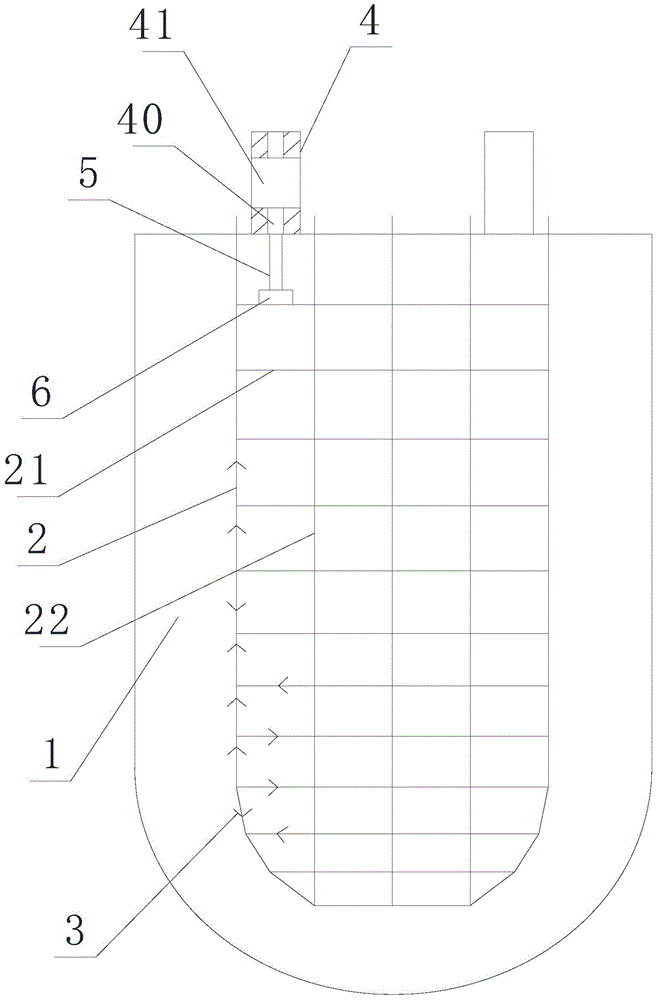

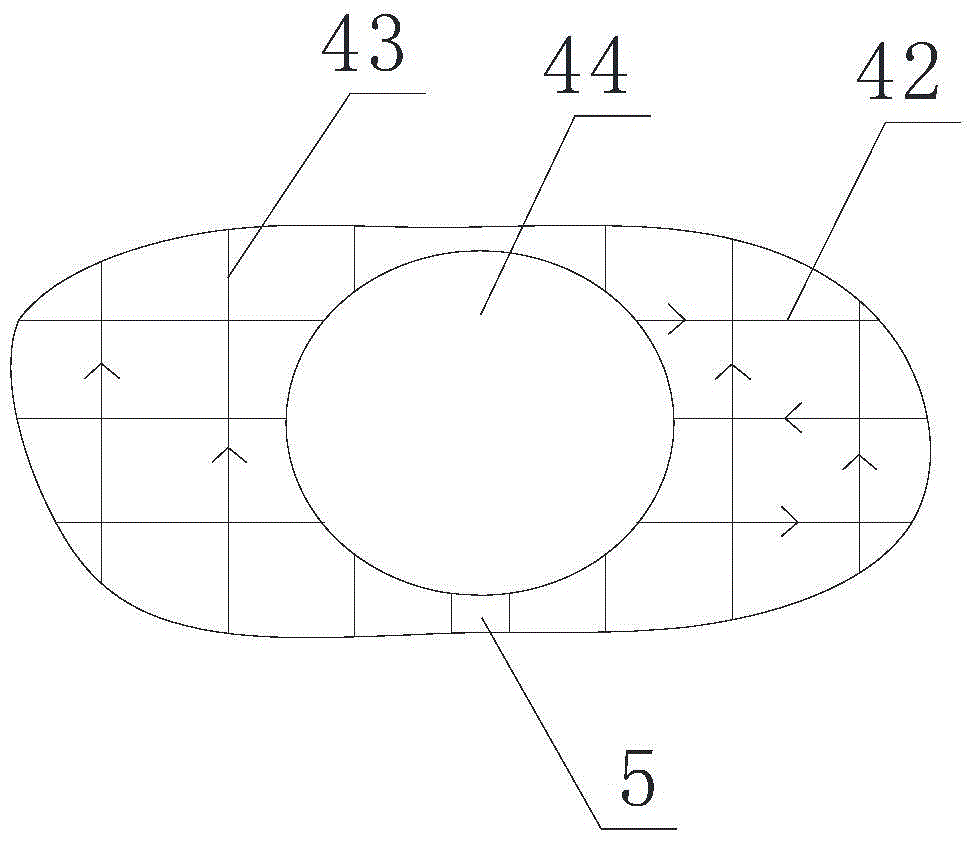

[0014] Such as figure 1 , figure 2 As shown, the high-temperature wear-resistant valve plate of the tertiary air duct includes a valve plate body 1. The rear end of the valve plate body 1 is square, and the front end is semicircular or trapezoidal. The inside of the valve plate body 1 is equipped with a heat-resistant Reinforcement frame 2, described heat-resistant reinforcement frame 2 is welded with a plurality of palladium nails 3, and the distribution of described palladium nails 3 is to increase gradually from the rear end to the front end of valve plate body 1, and the direction of each palladium nail 3 is different. Similarly, at least two bumps 4 are provided on the top of the valve plate body 1, and a reinforcement frame 40 is provided inside the bumps 4, and at least one lifting hole is provided on the reinforcement frame 40 to facilitate the lifting of the valve plate body 1. 41, the reinforcing frame 40 includes several horizontal ribs 42 arranged in parallel, se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com