Method for indirectly testing high-temperature strength of ultra-high temperature ceramic material

A technology of ultra-high temperature ceramics and high-temperature strength, which is applied in the direction of analysis of materials, material thermal analysis, and measuring devices, which can solve the problems of inability to predict the high-temperature strength of ultra-high-temperature ceramic materials, and achieve reliable prediction results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

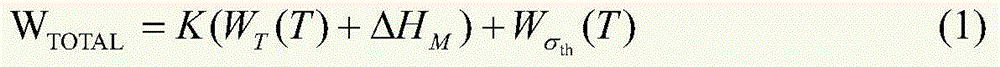

Method used

Image

Examples

Embodiment

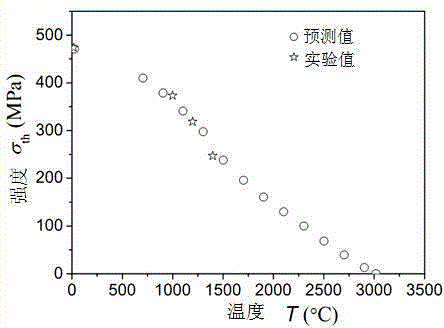

[0048] Take titanium carbide (TiC) ceramic material as example, implement this material high-temperature strength to predict, in conjunction with this example illustrate the concrete prediction step of the present invention:

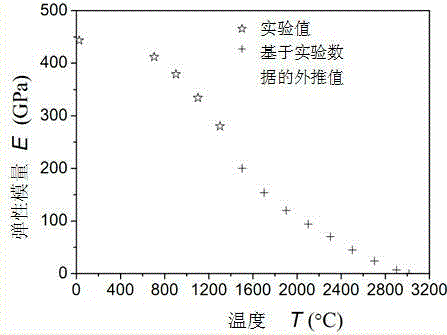

[0049] 1. Test the experimental data of the elastic modulus of ultra-high temperature ceramic materials as a function of temperature and the material strength and elastic modulus at the reference temperature

[0050] The experimental test of the change of elastic modulus with temperature adopts the mechanical performance testing device and method disclosed in the Chinese patent document CN 102944466A for ultra-high temperature oxidation environment. The TiC ceramic specimen is installed on the testing device, and the furnace door of the high-temperature furnace is closed. Heating to different predetermined temperatures, keeping warm, loading, recording the experimental data of the load and the elongation of the specimen, and obtaining the data of the elas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com