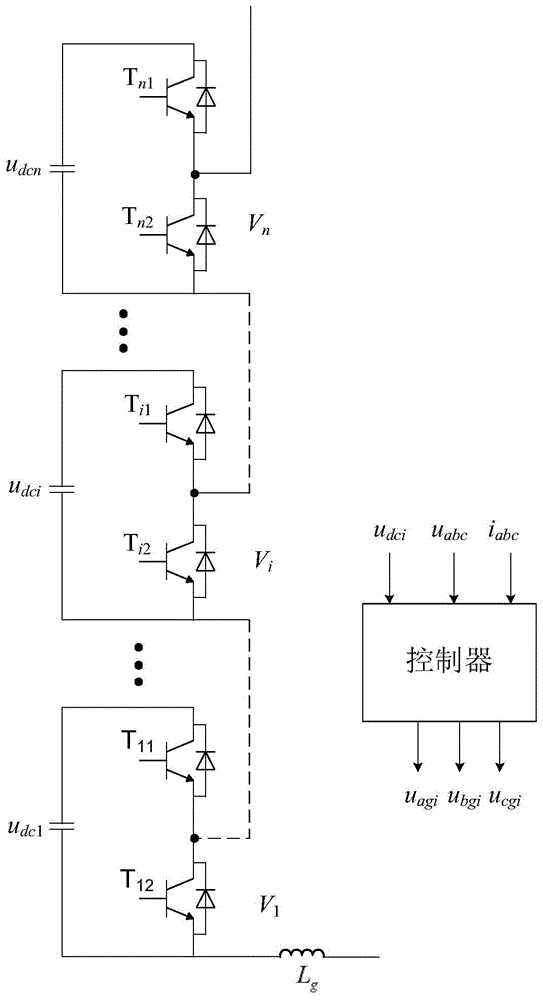

Half-bridge MMC (Modular Multilevel Converter) sub-module voltage control method

A modular multi-level, sub-module voltage technology, applied in the direction of converting AC power input to DC power output, electrical components, output power conversion devices, etc., can solve damaged sub-modules, DC capacitor voltage imbalance, DC capacitors voltage distortion and other problems, to achieve the effect of improving the level of safe operation, prolonging the service life and improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

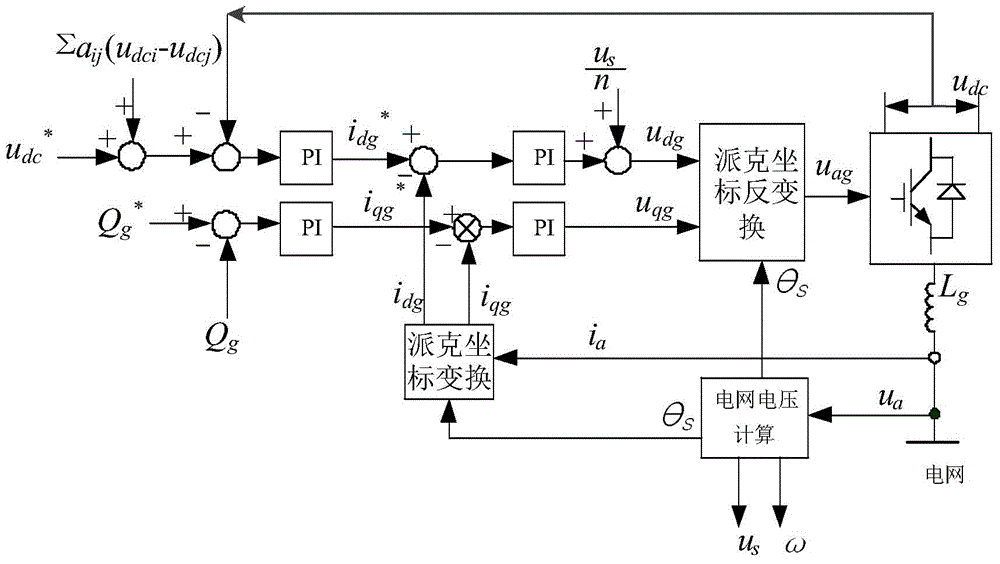

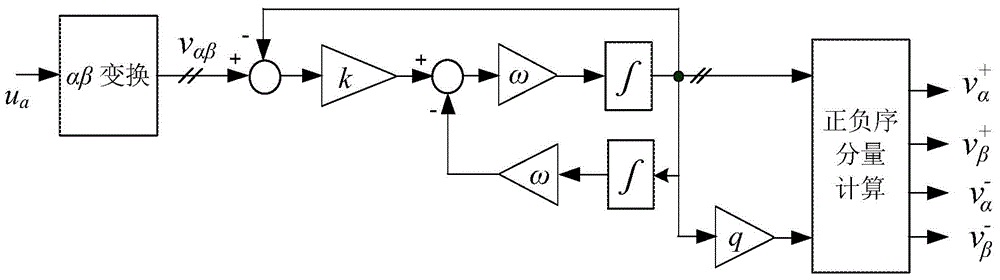

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0029] Detailed exemplary embodiments are disclosed below. However, specific structural and functional details disclosed herein are merely for purposes of describing example embodiments.

[0030] It should be understood, however, that the invention is not limited to the particular exemplary embodiments disclosed, but covers all modifications, equivalents, and alternatives falling within the scope of the disclosure. Throughout the description of the figures, the same reference numerals denote the same elements.

[0031] Also, it should be understood that as used herein, the term "and / or" includes any and all combinations of one or more of the associated listed items. Also it will be understood that when a component or unit is referred to as being “connected” or “coupled” to another component or unit, it can be directly connected or coupled to the other component or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com