Method for reinforcing reliability of plastic-substrate-contained three-dimensional circuit, and apparatus prepared by using the same

A three-dimensional circuit, reliability technology, applied in the direction of printed circuit manufacturing, printed circuit, electrical components, etc., can solve the problems that affect the reliability of LDS circuits, life without circuit boards, deformation of plastic substrates, etc., to achieve enhanced adhesion and reliability Enhances, enhances the effect of a firm bond

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

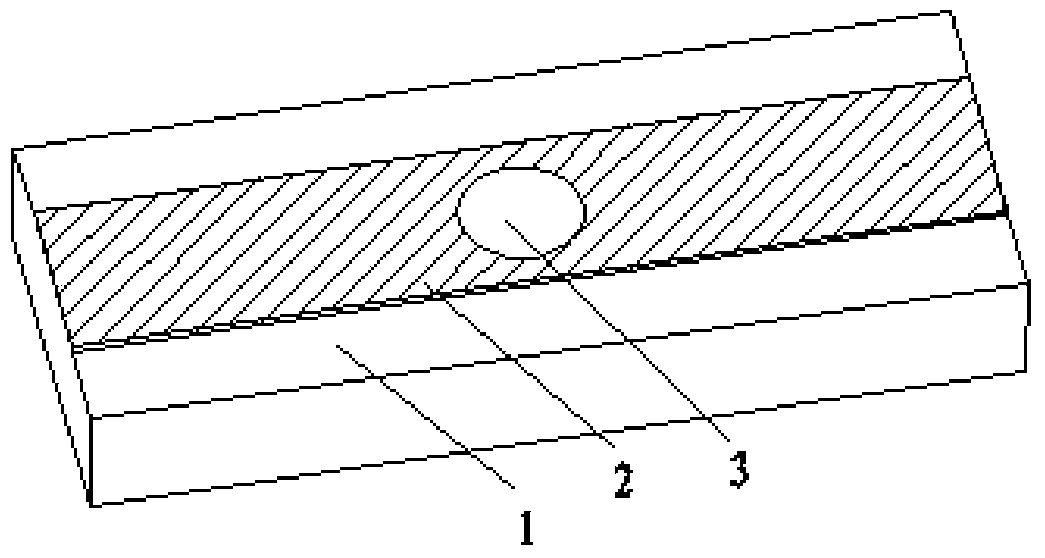

[0029] A method for enhancing the reliability of a three-dimensional circuit on a plastic substrate, comprising the following steps:

[0030] 1) First, form the through holes required to reinforce the three-dimensional circuit on the plastic structural member;

[0031] 2) Then the plastic structural parts with through holes obtained in step 1 are subjected to electroless plating, and in the process of electroless plating on the three-dimensional circuits on the plastic structural parts, the above-mentioned through holes form a metal layer through electroless plating to carry out the electroless plating on the three-dimensional circuits. reinforcement. Electroless plating is to place the plastic structural parts in the chemical plating pool. While forming the three-dimensional circuit on the surface of the plastic structural parts, a metal layer is chemically plated on the hole wall of the through hole, and the metal layer is attached to the hole wall. And connect the three-di...

Embodiment 2

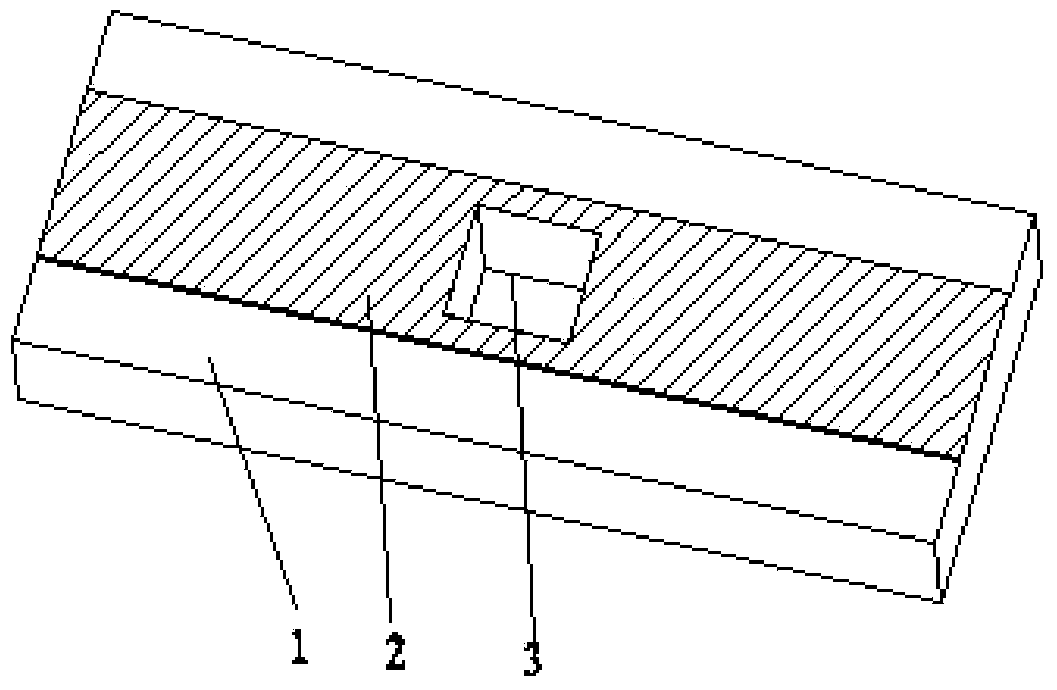

[0043] A method for enhancing the reliability of a three-dimensional circuit on a plastic substrate, comprising the following steps:

[0044] 1) First, form the blind holes required to reinforce the three-dimensional circuit on the plastic structural parts;

[0045] 2) Then carry out electroless plating to the plastic structural parts with blind holes obtained in step 1. During the electroless plating process to the three-dimensional circuit on the plastic structural part, the above-mentioned through holes form a metal layer through electroless plating to carry out the electroless plating on the three-dimensional circuit. reinforcement. Electroless plating is to place the plastic structural parts in the chemical plating pool. While forming the three-dimensional circuit on the surface of the plastic structural parts, a metal layer is chemically plated on the hole wall of the blind hole, and the metal layer is attached to the hole wall. And connect the three-dimensional circuit...

Embodiment 3

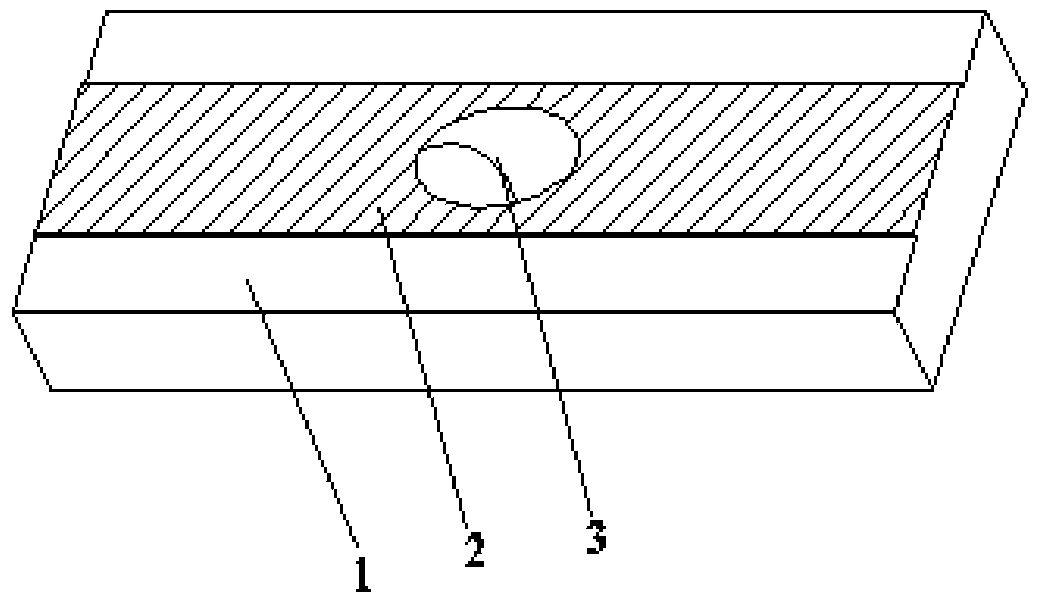

[0055] A method for enhancing the reliability of a three-dimensional circuit on a plastic substrate, comprising the following steps:

[0056] 1) First, form the through holes and blind holes required to reinforce the three-dimensional circuit on the plastic structural parts;

[0057] 2) Then carry out electroless plating on the plastic structural parts with through holes and blind holes obtained in step 1. In the process of electroless plating on the three-dimensional circuit on the plastic structural parts, the above through holes and blind holes form a metal layer through electroless plating , to strengthen the three-dimensional circuit. Electroless plating is to place the plastic structural parts in the chemical plating pool. While forming the three-dimensional circuit on the surface of the plastic structural parts, a metal layer is chemically plated on the walls of the through holes and blind holes, and the metal layer is attached to the The three-dimensional circuit on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com