Sliding cam system of reciprocating piston internal combustion engine with sliding grooves and guide elements arranged in x-shape

A technology of sliding cams and guiding elements, which is applied in the direction of engine components, machines/engines, valve devices, etc., can solve the problems of bifurcated reeds not being allowed, concerns about plastic deformation of guiding elements, and reduced guiding force, so as to improve durability properties, improved stiffness, and improved fatigue strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

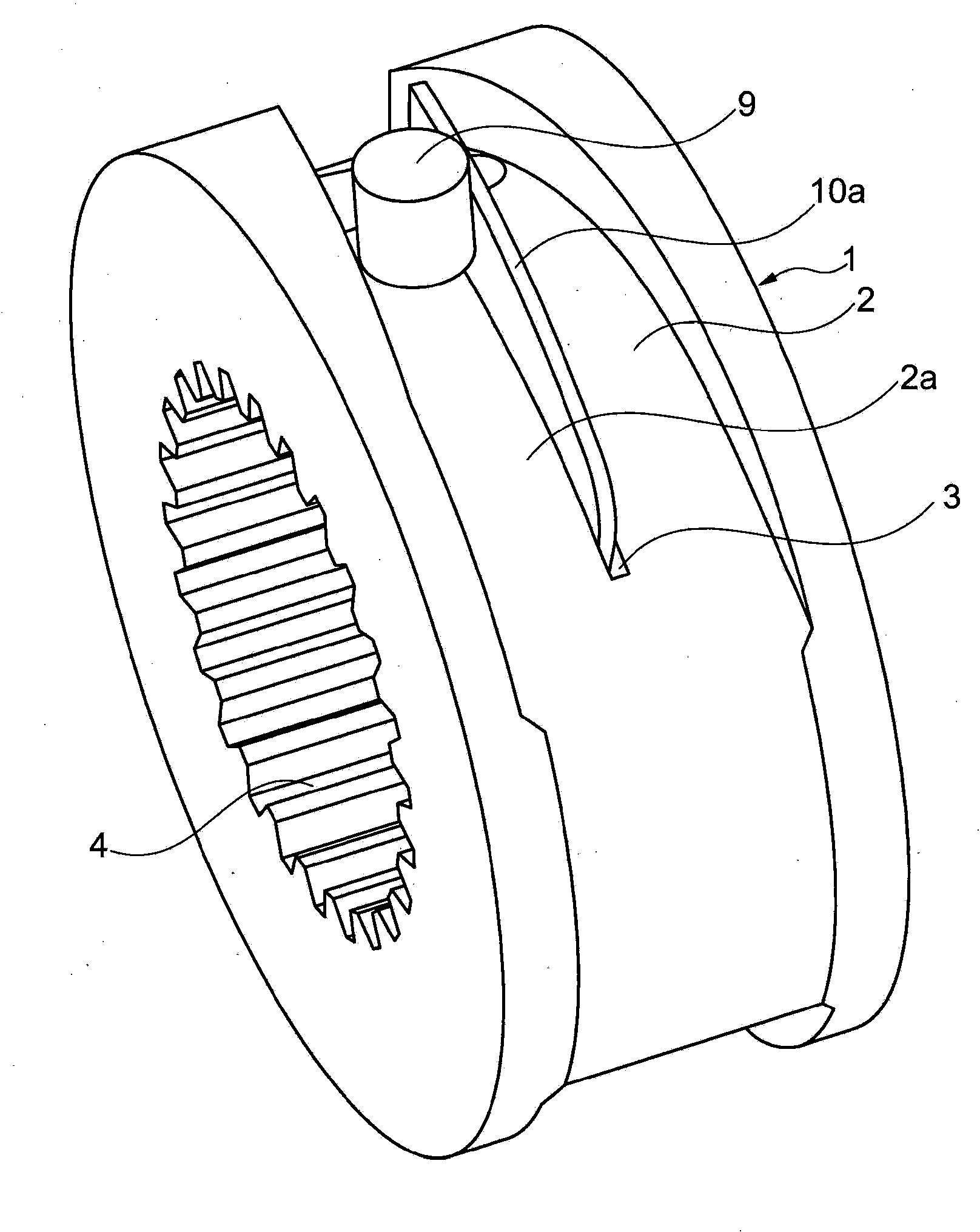

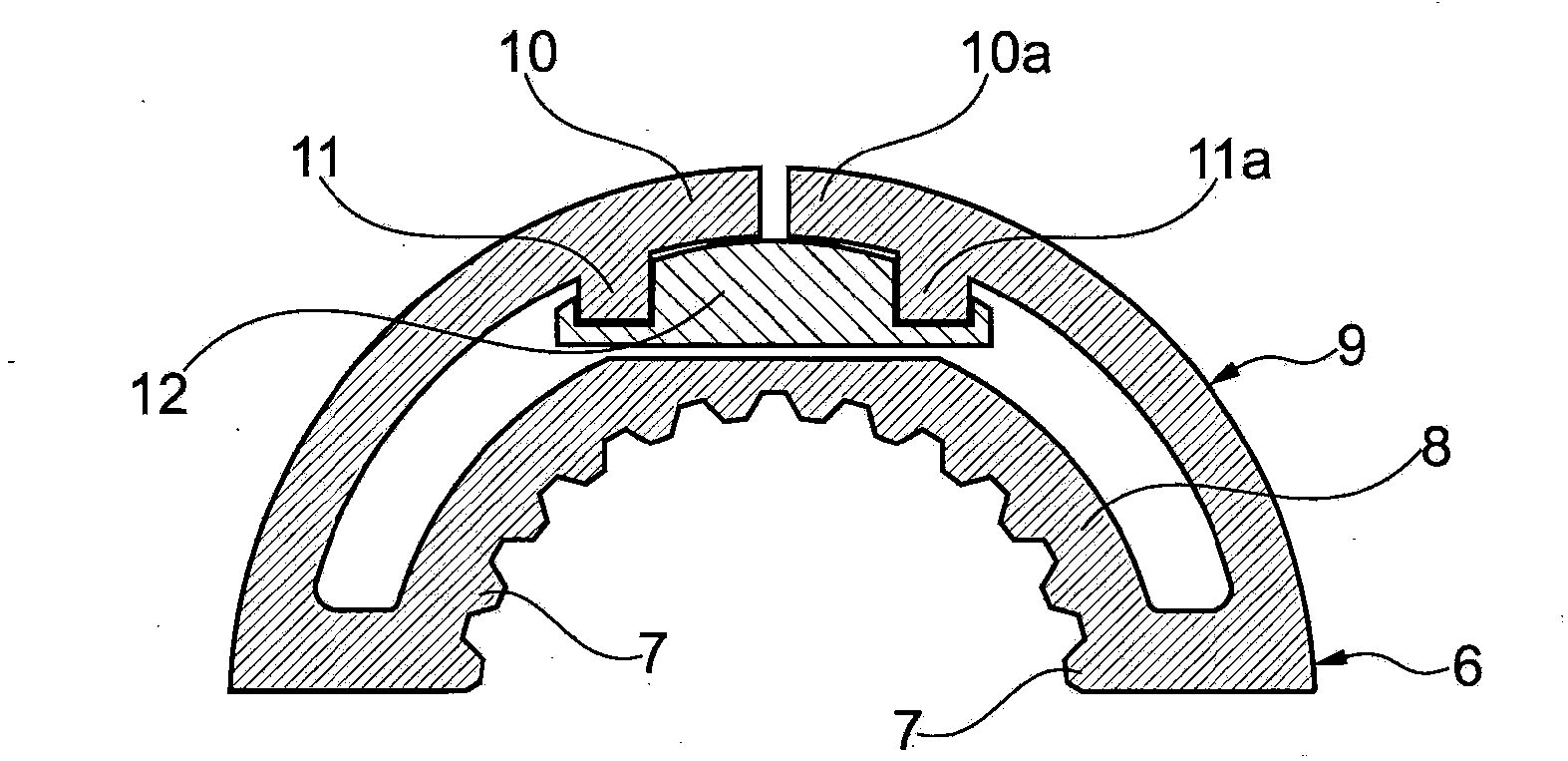

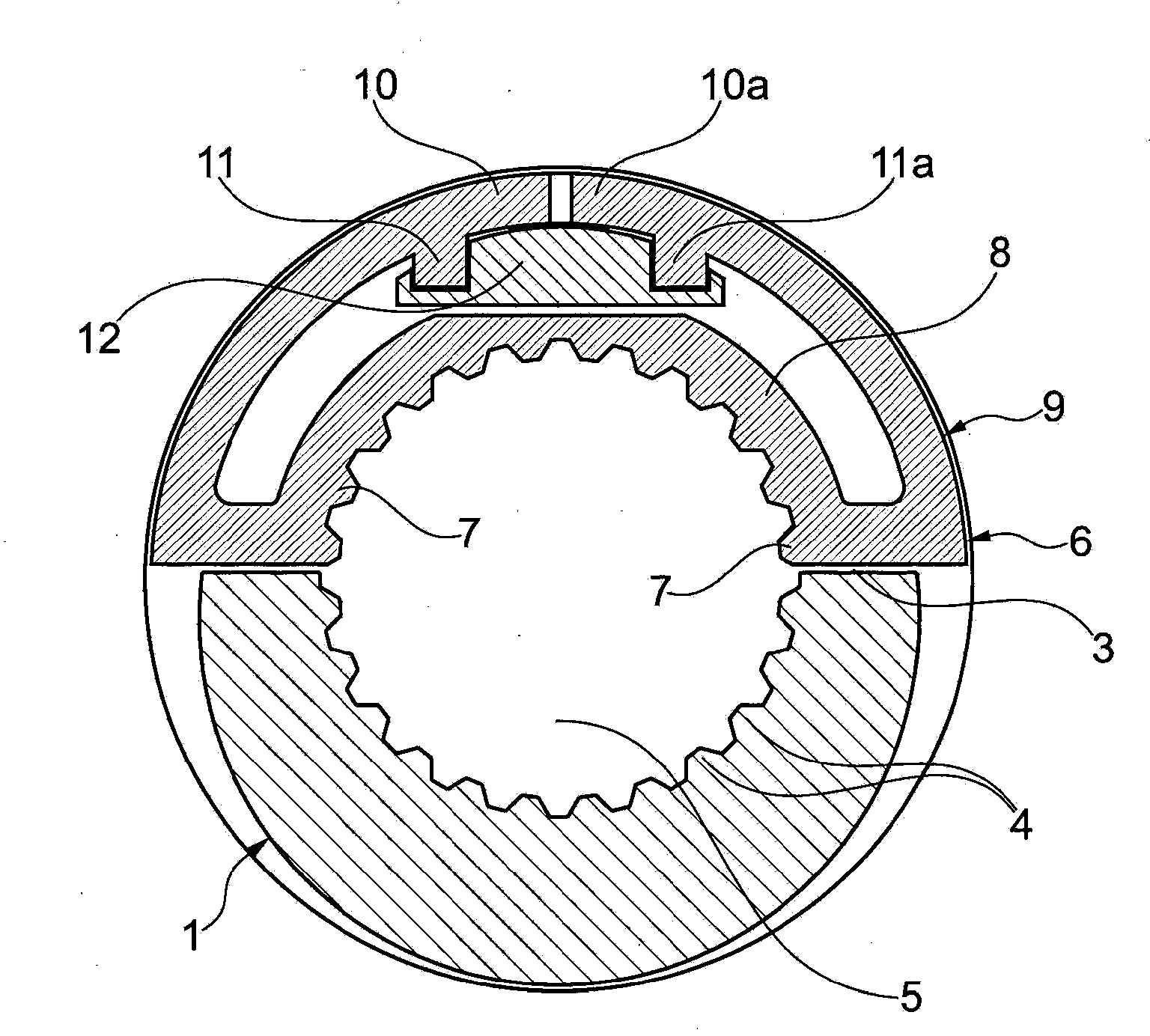

[0026] exist figure 1 and 12 , generally shown in detail, generally designated with 1 is the gate area, in which two X-shaped intersecting gates 2 and 2a are produced. The link area 1 can be formed as a separate moon disk, which is connected to the sliding cam element, but it can also form a unit with the sliding cam element, so that the sliding cam and the link area are arranged side by side.

[0027] Cutouts 3 are made in the chute area 1, more precisely in the chute bottoms of the chute 2 and 2a, such as in particular from image 3 Extends to the central axis of the sliding cam element as can be seen in . At the inner opening, the sliding cam element has an internal toothing 4 which is adapted to a pinion 5 . C-shaped spring 6, also known as C-spring loaded according to image 3 in the cutout 3. The C-spring 6 has internal teeth 7 which correspond to the internal toothing 4 on the slide cam element and likewise engage into the toothed shaft 5, so that a greater number ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com