Manufacturing method for constructing novel artificial fish reef by using low-carbon environment-friendly material

An artificial fish reef, low-carbon and environmentally friendly technology, applied in fish farming, application, climate change adaptation, etc., can solve the problems of environmental pollution in sea areas, easy to be washed away, etc., to alleviate environmental pollution, facilitate collection, and realize reuse Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with example the present invention will be further described.

[0022] How to make oyster shell fragments

[0023] Remove the oyster meat remaining in the oyster shell and remove the dirt on the surface of the oyster shell. The cleaned oyster shells are crushed, and after the crushed oyster shells are washed again, they are sequentially passed through mesh screens with apertures of 20 and 10 mm, and the fragments of oyster shells of 10-20 mm are boxed for preservation.

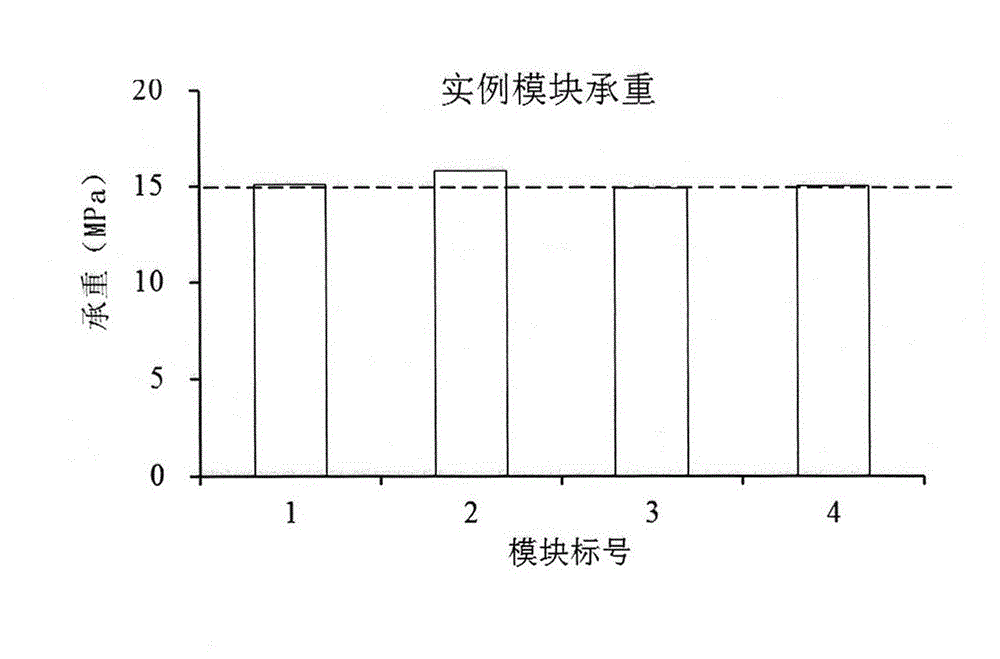

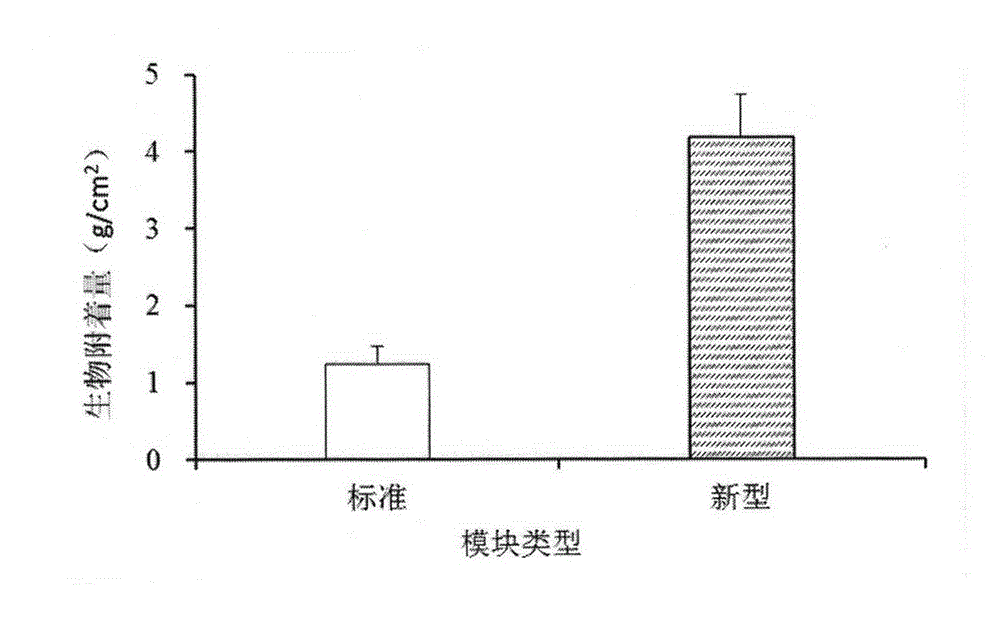

[0024] Fabrication of new reef modules

[0025] According to the proportion of cement, stones, oyster shell fragments, sand and water in the ratio of 336:952:106:640:185 kg / m3, weigh 1134g of cement, 3213g of stones, 358g of oyster shell fragments, 2160g of sand and 624g of water. is ±1%. Mix the above materials before pouring, and the pouring time should not exceed 15 minutes. The module is made by manual tamping, and the concrete mixture should be loaded into the mold in two l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com