Full-automatic upper surface glue spraying machine and control strategy thereof

A control strategy and glue spraying machine technology, which is applied in the direction of shoemaking machinery, footwear, and adhesive shoe parts, etc., can solve problems such as unsuitable for automatic installation and removal of shoe lasts, so as to improve the efficiency of glue spraying processing and improve efficiency , the effect of increasing the operating space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

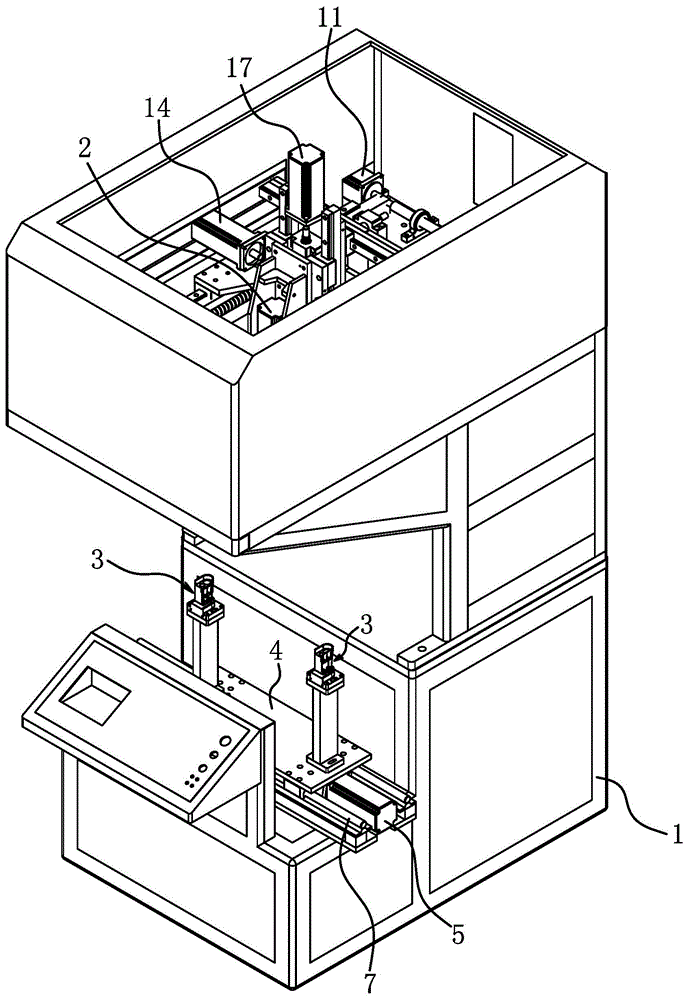

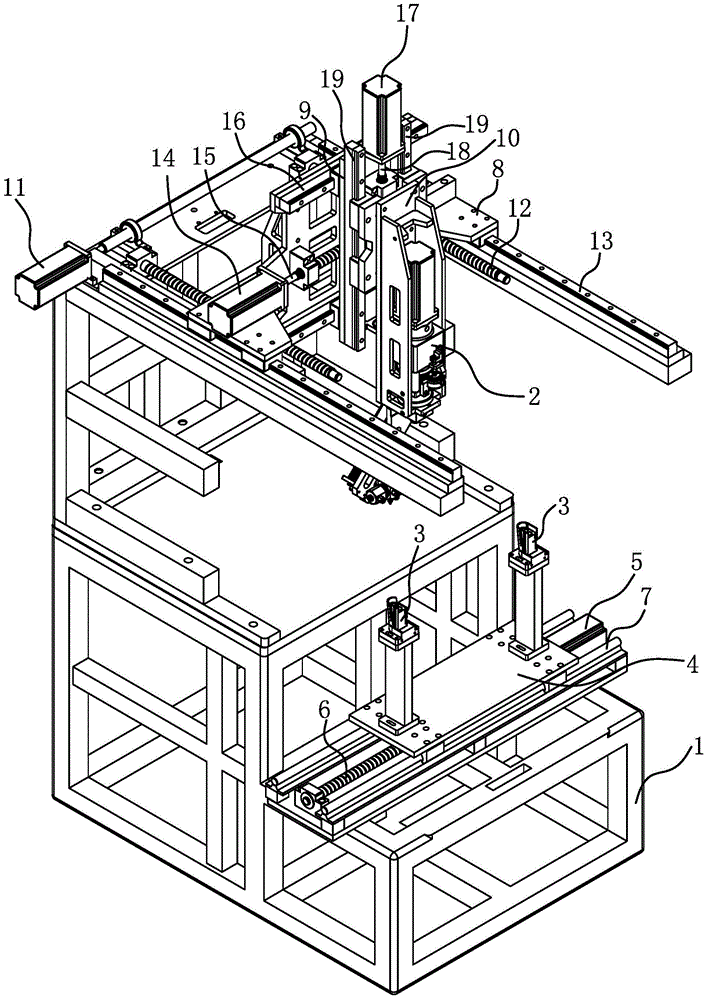

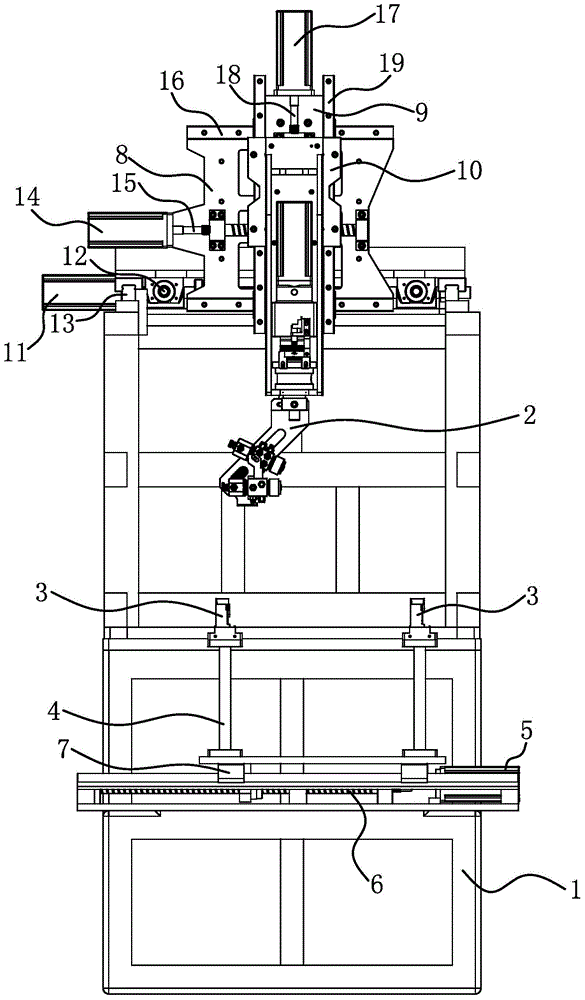

[0025] Such as Figure 1 to Figure 3 As shown, the automatic shoe upper surface glue spraying machine includes a frame 1, a set of automatic glue spraying components 2, two sets of shoe last positioning tooling 3 and a control unit.

[0026] Such as Figure 4 As shown, the shoe last positioning tool 3 includes a base 3a, the top surface of the base 3a is provided with a strip-shaped positioning groove 3b with one end open, and the bottom surface of the other end of the positioning groove 3b is provided with a magnet mounting hole. A magnet 3c is fixed in the magnet mounting hole. The base 3a includes a fixed part 3a1 and a movable side wall 3a2 of the positioning groove. A vertical spring 3d is arranged outside the fixed part 3a1. The upper end of the spring 3d is fixedly connected with the movable side wall 3a2 of the positioning groove. The lower end of the spring 3d It is fixedly connected with the fixed part 3a1. The width of the bottom surface of the positioning groove...

Embodiment 2

[0036] The structure and principle of this embodiment are basically the same as those of Embodiment 1. The basic similarities will not be described in detail, and only the differences will be described. The difference is that the shoe last positioning tool switching mechanism used is different: shoe last positioning tool switching The mechanism includes a cylinder and a linear guide rail; the movable seat and the frame are connected through the linear guide rail; the cylinder body of the cylinder is fixed on the frame, and the piston rod of the cylinder is fixedly connected with the movable seat. The solenoid valve connected with the cylinder is electrically connected with the control unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com