Brush bristle cutting equipment

A brush and hair cutting technology, applied in the field of brush hair cutting equipment, can solve the problems of inconvenient use, hidden dangers of accidents, falling off of the brush, and difficulty in one-time cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The preferred embodiments of the present invention will be described in further detail below in conjunction with the accompanying drawings.

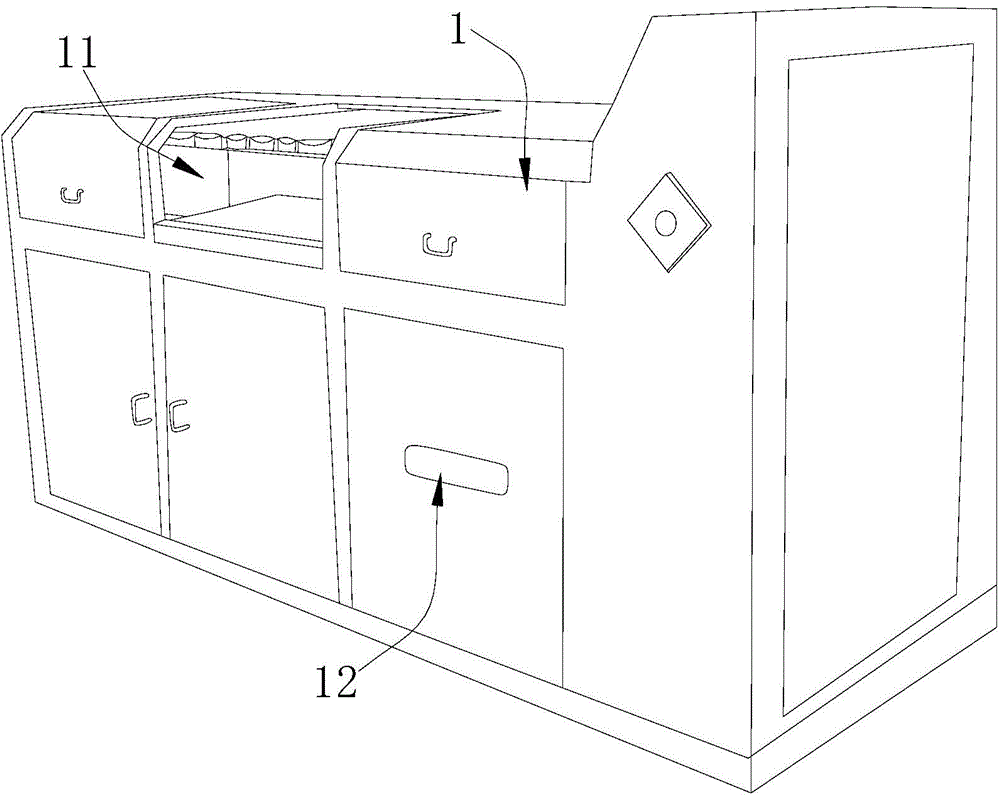

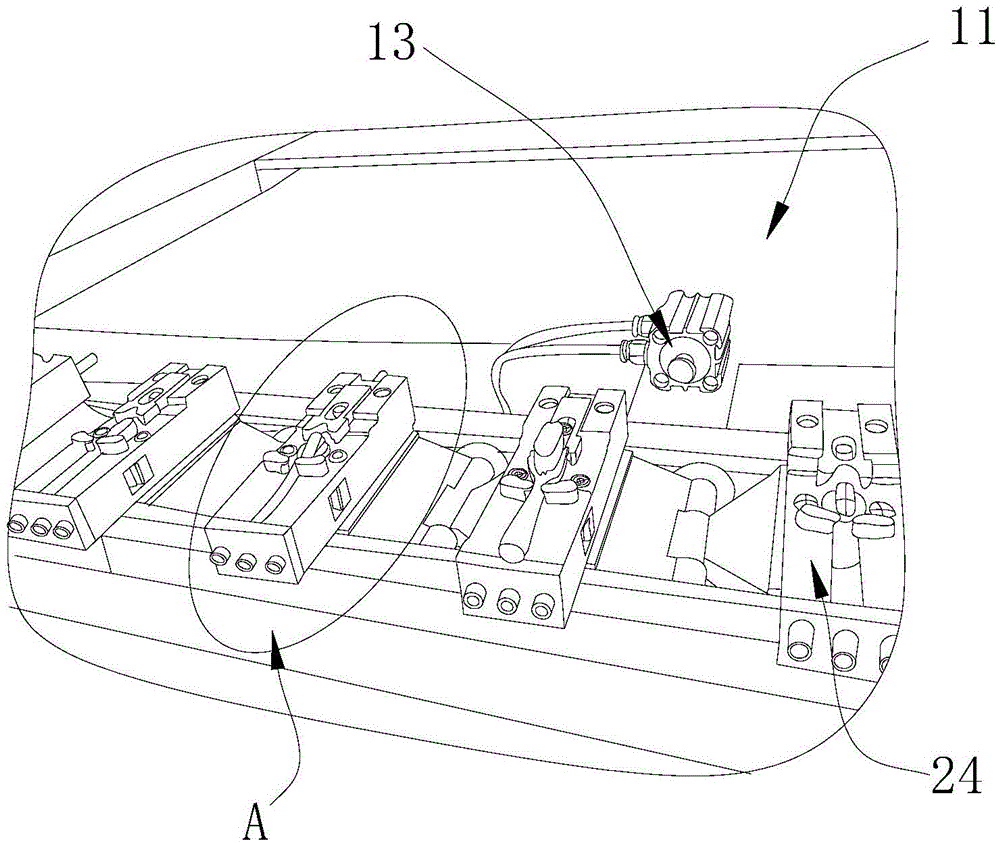

[0022] Such as Figure 1~Figure 9 A kind of hair brush hair cutting equipment shown, comprises cabinet 1, and the feeding mechanism and the hair cutting mechanism that are arranged in the cabinet 1, have the discharge opening 11 that is used to place the brush to be processed on the cabinet 1, and are used for discharging The discharge port 12 of the finished brush, the discharge opening 11 of the cabinet 1 is provided with a charging cylinder 13, the inside of the cabinet 1 is provided with a discharge hopper 15, the output end of the discharge hopper 15 corresponds to the discharge port 12, and A discharge cylinder 14 is provided above the input end of the hopper 15 .

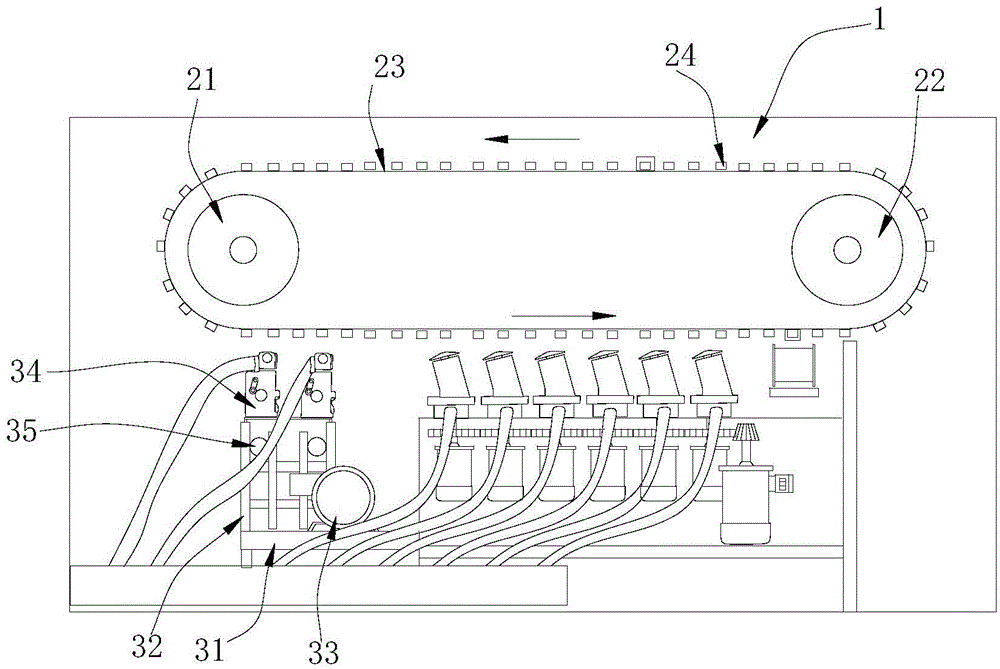

[0023] Described feeding mechanism comprises stepping motor, driving shaft 21, driven shaft 22, feeding belt 23 and a plurality of hairbrush fixtures 24, and dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com