A New Type of Twisted Sheet Tube Investment Mold

A technology of twisted sheet tube and investment pattern, which is applied in the direction of casting mold, core, casting mold composition, etc., can solve the problems of large heat capacity, casting defects, complex structure of twisted sheet tube, etc., achieve reasonable structure, avoid waste, and prolong service life The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

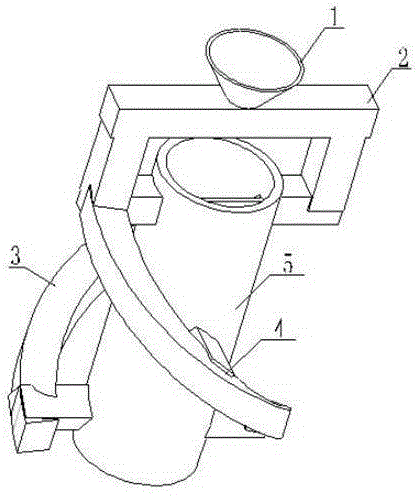

[0011] The present invention will be further described below in conjunction with accompanying drawing:

[0012] Referring to the accompanying drawings, a new twisted sheet tube investment mold includes a sprue cup 1 and a twisted sheet tube 5. It is characterized in that: a runner 2 is arranged under the sprue cup 1, and the two sides of the lower end of the runner 2 The rotary runner 3 is symmetrically arranged, and the rotary runner 3 is connected to the twisted sheet tube 5 through several gates 4; The directions are consistent; the gates 4 are arranged symmetrically.

[0013] During concrete implementation, molten steel is injected into the runner from the top sprue cup 1 during pouring, enters the rotary runner 3 from the runner 2, and is injected into the cavity of the twisted sheet tube 5 by several inlets 4 respectively. Compared with a new type of traditional twisted sheet tube investment mold, the present invention has the following advantages: 1. The flow mode of m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com