A method and device capable of controlling automatic clamping and error-proofing of pneumatic clamps

A technology of automatic clamping and pneumatic clamping, which is applied in clamping devices, positioning devices, manufacturing tools, etc., can solve problems such as low efficiency, unstable precision, and unguaranteed safety, and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

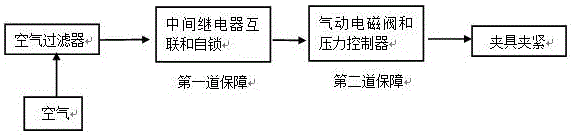

[0024] Such as Figure 4 A device that can control the automatic clamping and error prevention of pneumatic clamps is shown, including a distribution box 1, the distribution box 1 is connected to the main switch 2, the main switch 2 is connected to the DC switching power supply 3, and the switching power supply 3 is connected to the three-position five The pneumatic solenoid valve 4 is connected, and the three-position five-way pneumatic solenoid valve 4 is equipped with S1 switch 5, M21 relay 6, D1 coil 7, M24 relay 8, D2 coil 9, M25 relay 10, S2 pressure controller 11 And KM1 coil 12, M21 relay 6 and D1 coil 7 are connected in series, M24 relay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com