Irregularly-shaped thin-walled bushing dismounting tool

A technology for removing tools and bushings, which is applied in the manufacture of tools and hand-held tools, etc. It can solve the problems of difficult disassembly work, inconvenient operation, and difficulty in realization, and achieve the effect of quick and labor-saving disassembly process, ingenious and simple structure, and high promotional value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

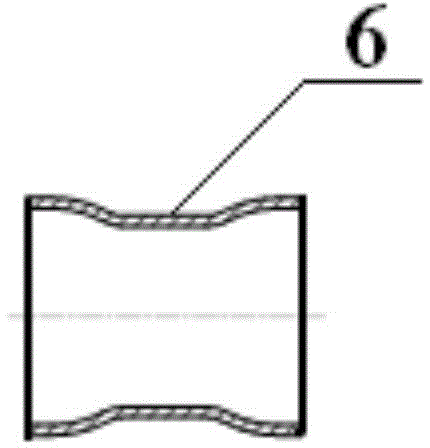

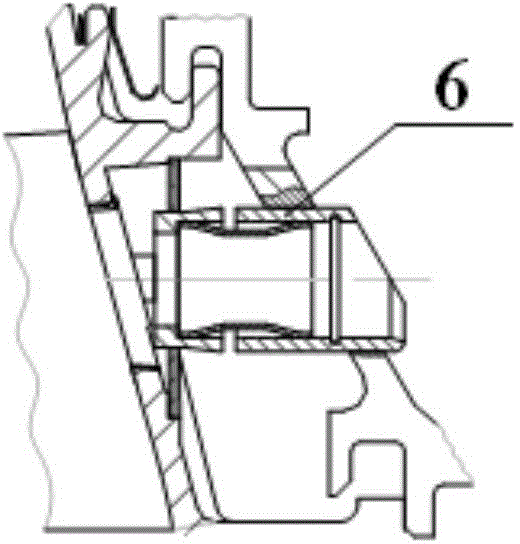

[0025] see figure 1 , 2. Since the two ends of the special-shaped thin-walled bush 6 are large and the middle is small, its elasticity is good, the inner diameter is less than 15mm, and the thickness is about 1mm. 0~0.1mm, and the outer diameters of both ends of the bush are respectively connected to the cooling air hole of the engine guide vane and the cooling air hole of the casing, the disassembly process is very difficult.

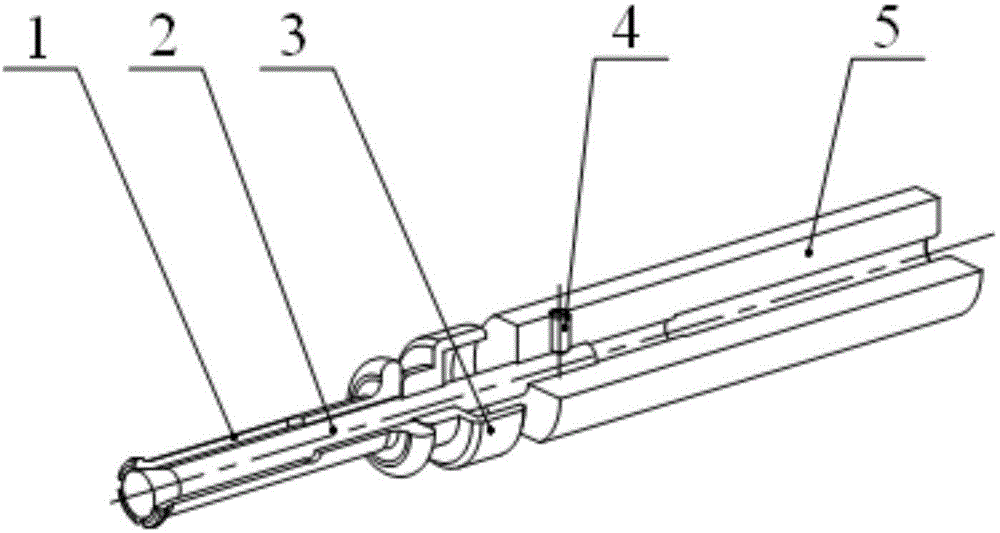

[0026] see image 3 , 4, 5. The overall structure of the present invention includes an expansion sleeve 1 installed on the head of the handle 5 with a wall thickness of 1 mm to 1.5 mm. The center of the expansion sleeve 1 is equipped with an expansion shaft 2. The expansion sleeve 1 and the expansion shaft 2 have a taper of 15. °~30° trumpet-shaped head, the outer diameter of the small end of the expansion sleeve 1 head is 0.1mm-0.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com