Slicer

A technology of a slicer and the other side, applied in metal processing and other directions, can solve the problems of uneven slice thickness, unsafe, scratched fingers, etc., and achieve the effect of uniform slice thickness, reasonable structure and small workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

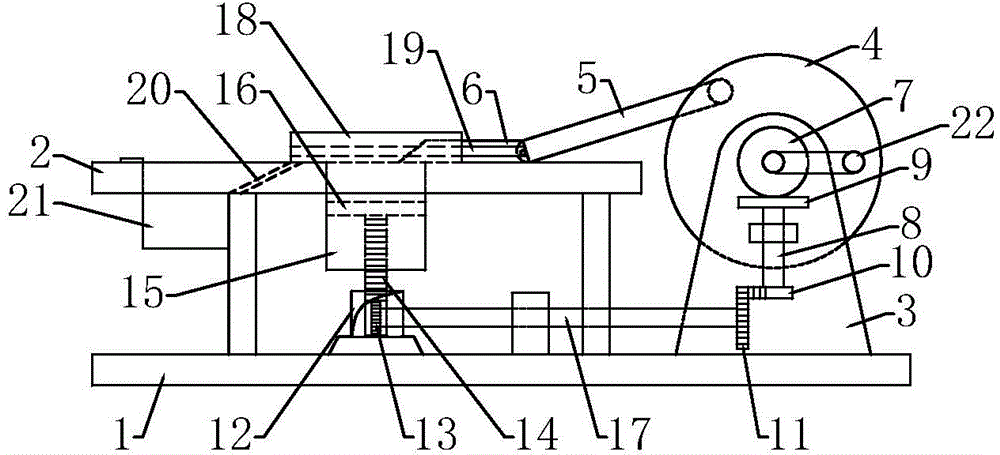

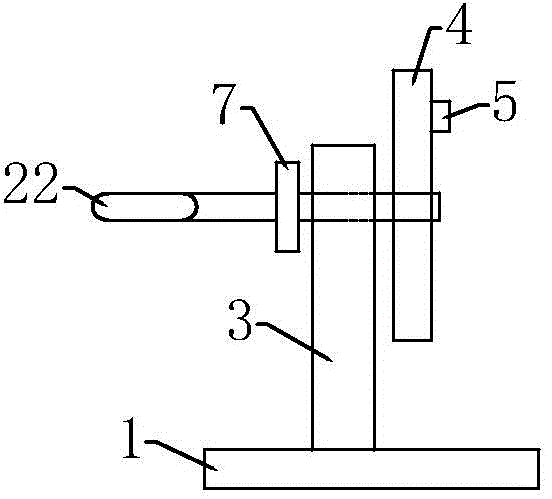

[0011] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0012] like Figure 1-Figure 2 As shown in , this embodiment includes a base 1, on one side of the base 1 is provided with a horizontally arranged operating platform 2, on the other side of the base 1 is provided with a driving device, the driving device includes a fixed on the base 1 A vertically arranged turntable 4 is movably installed on the support 3 through a rotating shaft fixed on it, and one end of a connecting rod 5 is eccentrically and movably connected to one side of the turntable 4, and the other end is connected to a horizontally arranged on the console. The rear end of the cutting knife 6 on the 2 is movably connected, and the end of the rotating shaft on the other side of the rotating disk 4 passes through the support 3 to be connected wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com