Automatic magnetic powder punching device

A punching device and automatic technology, applied in metal processing, etc., can solve problems such as poor oxidation, difficulty in packing mineral powder, and decline in product qualification rate, and achieve the effect of uniform punching, saving labor costs, and not easy to collapse

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with the accompanying drawings by means of specific embodiments:

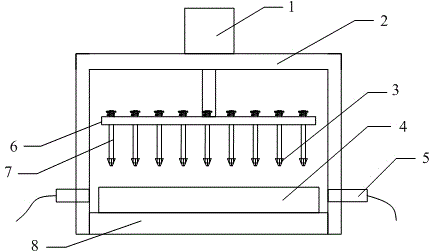

[0013] Such as figure 1 The magnetic powder automatic punching device shown includes a conveyor belt 8, a fixed frame 2, a power cylinder 1 and a punching plate, the fixed frame 2 is a portal frame and is arranged on the conveyor belt 8, and the power cylinder 1 is fixed on the beam of the fixed frame. The perforated disk is fixedly connected with the telescopic rod of the power cylinder 1. The perforated disk includes a disk surface 6 and a punching rod 7. The disk surface 6 is provided with a plurality of equidistant array mounting holes, and the punching rod 7 passes through the mounting holes and can slide relatively. , between the punching rod 7 and the disc surface 6 are fixedly connected by a spring, the end of the punching rod 7 is provided with a cross punching head 3, and the vertical pile of the fixed frame 2 is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com