Rotary press roller clutch press with novel eccentric bushing device

An eccentric sleeve, printing press technology, applied in rotary printing presses, printing presses, printing and other directions, can solve the problems of high repair cost, long cycle and high cost, and achieve the effect of avoiding direct wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

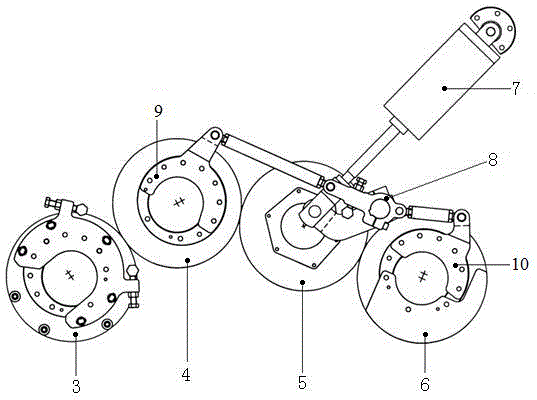

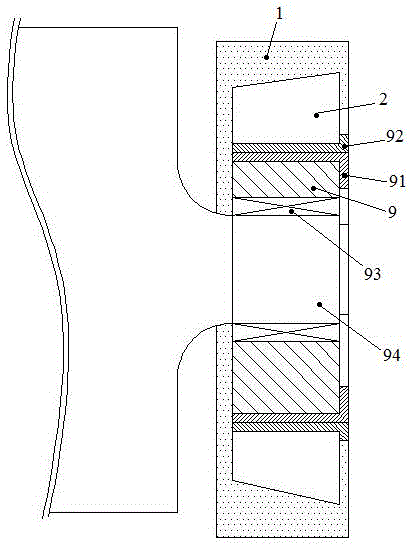

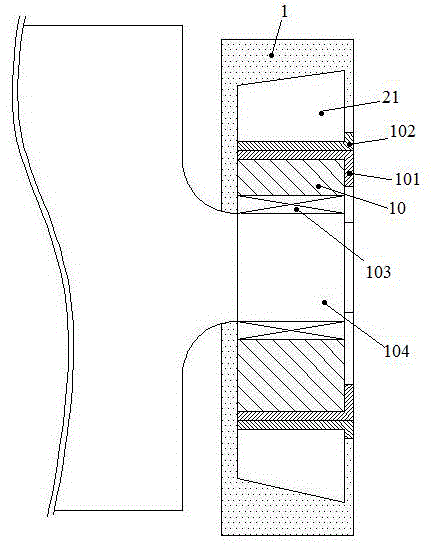

[0027] See attached figure 1 , figure 2 and image 3 The present invention is further described.

[0028] The invention relates to a cylinder clutch press of a rotary printing machine with a new type of eccentric sleeve device, which is characterized in that the structure includes plate cylinders A (3) which are installed on the wallboard (1) through the wallboard hole (2) and connected sequentially ), rubber cylinder A (4), rubber cylinder B (5), printing plate cylinder B (6), driving cylinder (7) and action link mechanism (8);

[0029] The action link mechanism (8) is respectively connected with the rubber cylinder A (4) and the plate cylinder B (6), and the driving cylinder (7) is connected with the action link mechanism (8);

[0030] The rubber cylinder A (4) is provided with an eccentric sleeve (9) of the rubber cylinder A, and the printing plate cylinder B (6) is provided with an eccentric sleeve (10) of the printing plate cylinder B;

[0031] The outer wall of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com