U-shaped shock absorption fork leg formed by single pipeline and manufacturing method of U-shaped shock absorption fork leg

A processing method, U-shaped technology, applied in steering mechanism, bicycle accessories, transportation and packaging, etc., can solve the problems of rough appearance, not light enough, and low strength of the shock absorber fork, and achieve smooth appearance, light weight and good strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

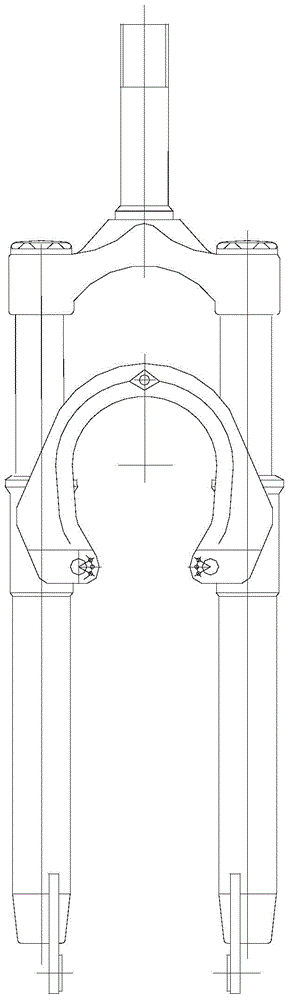

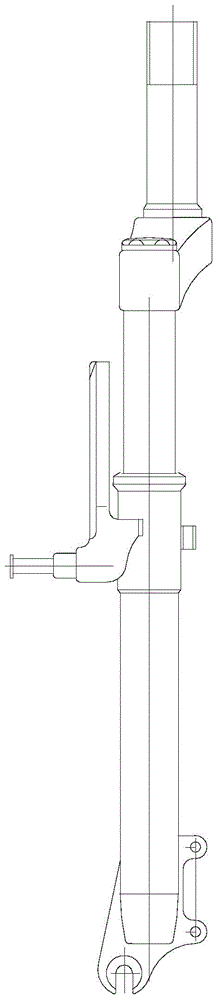

[0085] like Figure 5 to Figure 7 As shown, this embodiment 1 discloses a U-shaped shock-absorbing fork leg formed from a single pipe, which mainly includes a U-shaped lap section 1, two fork leg sections 3, and two fork end sections 4 , The U-shaped overlapping section 1, the fork leg section 3, and the fork end section 4 are integrally formed by pipe materials.

[0086] The U-shaped overlapping section 1 is located at the top of the two fork leg sections 3 and connects them to each other. The U-shaped overlapping section 1 gradually bends forward with a certain arc from the bottom to the top, such as Image 6 shown; or the U-shaped overlapping section 1 gradually bends back in a certain arc from the bottom to the top, as Figure 7 shown. It should be noted that the "front" and "rear" directions mentioned in this application document are based on the front and rear directions of a bicycle or electric bicycle. There is an arc 7 at the position where the U-shaped lap sectio...

Embodiment 2

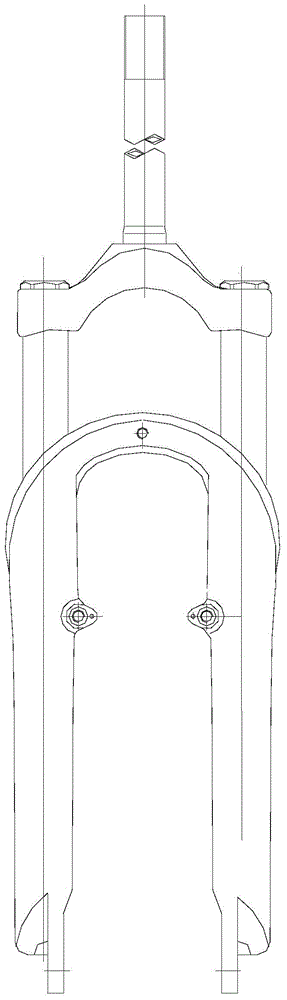

[0101] like Figure 25 to Figure 27 As shown, this embodiment discloses a U-shaped shock-absorbing fork leg formed from a single pipe, which mainly includes a U-shaped lap section 1, two fork leg sections 3, and two fork end sections 4, The U-shaped lap section 1 , the fork leg section 3 and the fork end section 4 are integrally formed by pipe material, and the pipe wall thickness of the pipe material is 0.5-5.0 mm.

[0102] The U-shaped overlapping section 1 is located at the top of the two fork leg sections 3 and connects them to each other. The U-shaped overlapping section 1 gradually bends forward with a certain arc from the bottom to the top, such as Figure 26 shown; or the U-shaped overlapping section 1 gradually bends back in a certain arc from the bottom to the top, as Figure 27 shown. The U-shaped overlapping section 1 is partially cut away from the pipe material longitudinally, so that it has a C-shaped pipe section formed by a single-layer pipe wall.

[0103] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com