Improved yarn guide frame

An improved technology for the yarn guide frame, which is applied in the direction of conveying filamentous materials, thin material handling, transportation and packaging, etc. It can solve the problems of longitudinal thread tension, low work efficiency, yarn breakage, etc., and prevent over-tightening Stretching, improving work efficiency and reducing frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

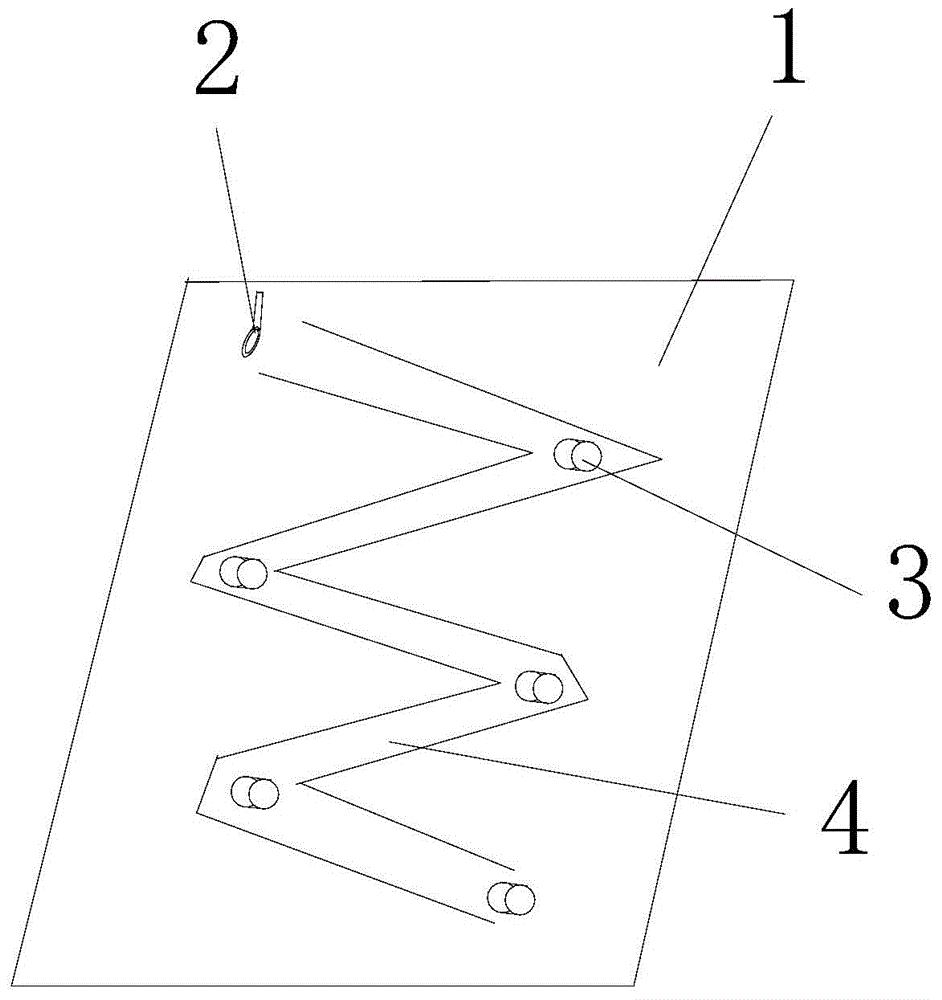

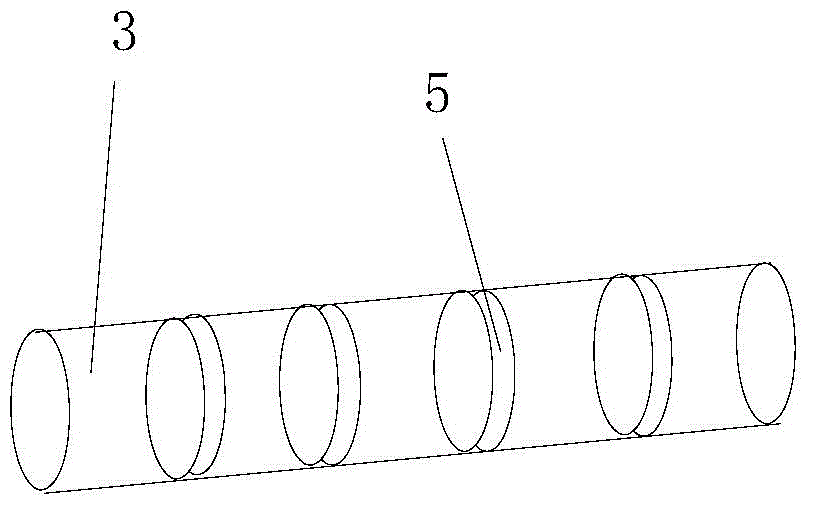

[0015] Such as figure 1 , figure 2 An improved yarn guide frame shown includes an installation base plate 1, the installation base plate 1 is equipped with guide wire hooks 2 and guide wire rods 3, and the described guide wire hooks 2 are located on the upper part of the installation base plate 1, and several Guide wire rod 3, the described installation base plate 1 is provided with guide groove 4, and described guide groove 4 is provided with rubber layer, and described guide wire rod 3 is installed in guide groove 4 and compresses described rubber layer. Described guide wire rod 3 is five. The guide grooves 4 are distributed in a broken line. The guide wire rod 3 is arranged at the turning point of the guide groove 4 . A limiting groove 5 is arranged on the guide wire rod 3 .

[0016] The invention has a simple structure, can prevent the yarn from changing direction when it moves, and prevent the yarn from being too tight, so that the distance between the guide wire ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com