Anaerobic fermentation tank for sludge treatment

A technology for anaerobic fermentation tank and sludge treatment, which is applied in biological sludge treatment, water/sludge/sewage treatment, special treatment targets, etc. , Sludge efficiency decline and other problems, to achieve the effect of efficient growth, good heat dissipation effect, and shorten the time spent

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

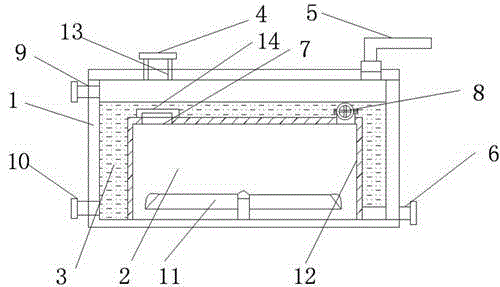

[0015] Example 1: Such as figure 1 An anaerobic fermentation tank for sludge treatment is shown. The fermentation tank is a rectangular shell 1, and the top of the shell 1 is provided with a feed port 4 and an exhaust port 5. The shell 1 is provided with a discharge port 6 on the side, a sealed rectangular fermentation tank 2 is provided in the shell 1, and a sealed heat transfer tank 3 is provided between the fermentation tank 2 and the shell 1. The bottom of the fermentation tank 2 is provided with an electric stirring paddle 11, the top of the fermentation tank 2 is provided with a secondary feed port 7 and a waterproof breathable valve 8, and the secondary feed port 7 is provided at the feed port. Directly below 4, the discharge port 6 is fixedly connected to the bottom of the fermentation tank 2.

Example Embodiment

[0016] Example 2: Such as figure 1 As shown, the top of the liquid-sealed heat transfer tank 3 is provided with a reflux liquid inlet 9 and the bottom is provided with a reflux liquid outlet 10; through the reflux inlet / outlet ports 9 and 10 on the liquid-sealed heat transfer tank 3, It is convenient to circulate the reflux liquid, and at the same time use the heated reflux liquid for other heat preservation equipment, which is convenient for the comprehensive utilization of energy.

Example Embodiment

[0017] Example 3: Such as figure 1 As shown, the feed port 4 is provided with a telescopic feed tube 13, and the telescopic feed tube 13 fixedly connects the feed port 4 and the secondary feed port 7 into a whole; through the telescopic feed tube 13. It is convenient to connect the feed port 4 and the secondary feed pipe 7 to facilitate the passage of sludge into the fermentation tank 2. The operation is simple and convenient, and the overall sealing performance of the device is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com