A kind of preparation method of surface porous niti shape memory alloy

A memory alloy, surface porous technology, applied in pharmaceutical formulations, anodizing, coatings, etc., can solve problems such as non-valve metal, and achieve the effects of low Ni content, promotion of exchange, and uniform pore size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

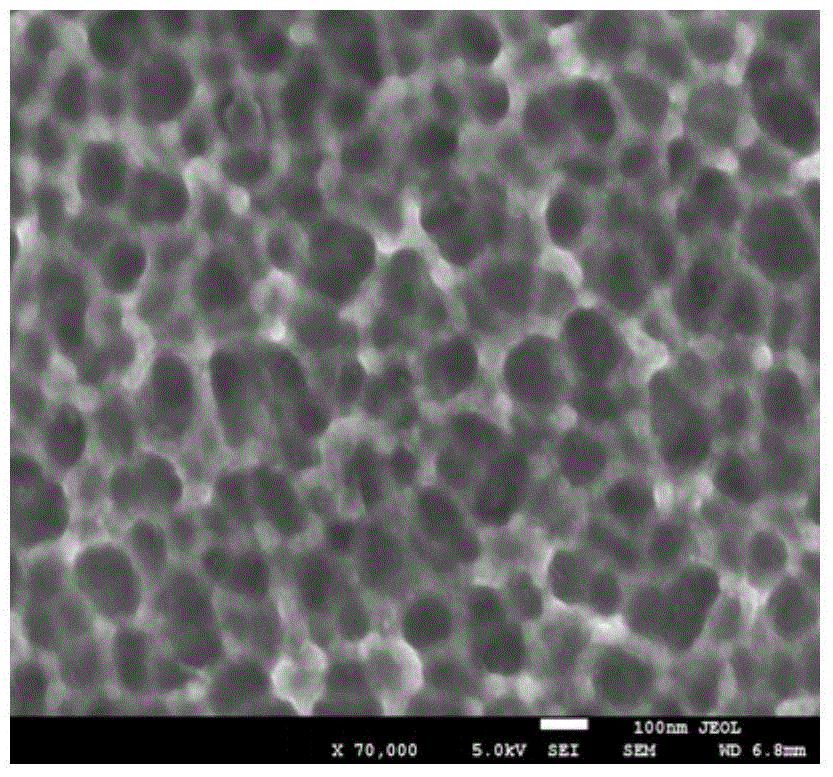

Embodiment 1

[0035] The surface of medical NiTi shape memory alloy was modified according to the following steps

[0036] Step 1: NiTi alloy surface pretreatment, followed by degreasing, SiC sandpaper grinding, mechanical polishing and ultrasonic cleaning;

[0037] Step 2: Anodizing treatment, put the NiTi alloy after ultrasonic cleaning into the electrolyte, use the NiTi alloy as the positive electrode, the graphite plate as the negative electrode, and control the temperature of the electrolyte to be 30 ° C ± 5 ° C, using a DC voltage stabilized power supply, in Anodizing treatment under the condition of constant voltage 35V for 90min; wherein, the electrolyte is a mixed solution prepared by ammonium fluoride and ammonium sulfate with glycerol, ethylene glycol and deionized water as solvents, and the concentrations thereof are respectively 0.3 mol / L and 0.2 mol / l;

[0038] Step 3: Rinse with deionized water and then dry naturally to obtain a surface-connected and surface-porous NiTi shap...

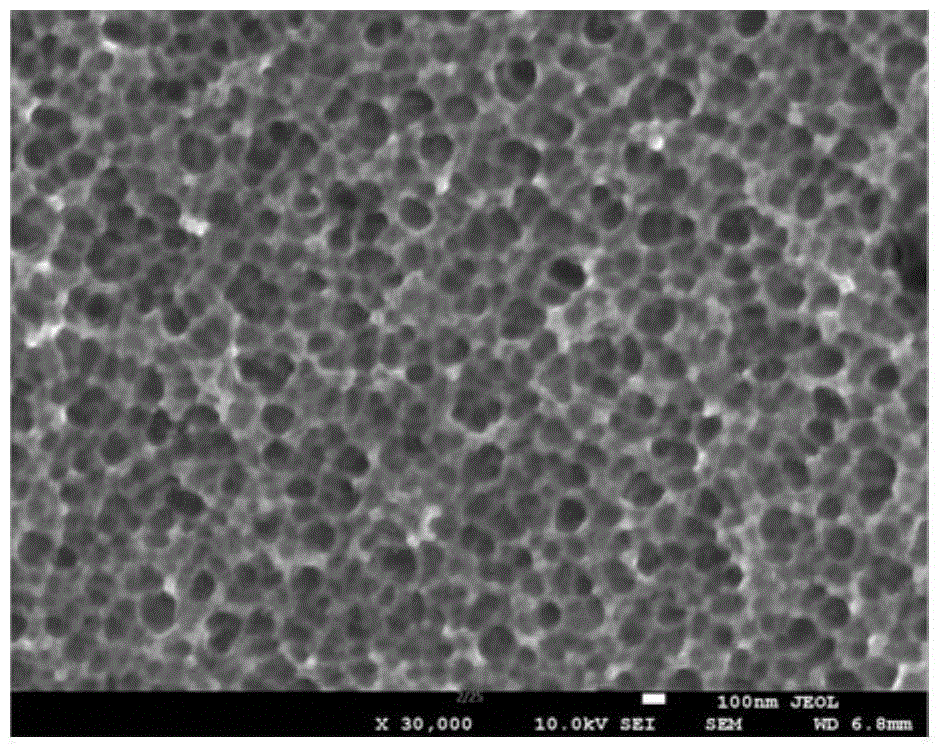

Embodiment 2

[0044] The surface of medical NiTi shape memory alloy was modified according to the following steps

[0045] Step 1: NiTi alloy surface pretreatment, followed by degreasing, SiC sandpaper grinding, mechanical polishing and ultrasonic cleaning;

[0046]Step 2: Anodizing treatment, put the NiTi alloy after ultrasonic cleaning into the electrolyte, use the NiTi alloy as the positive electrode, the graphite plate as the negative electrode, and control the temperature of the electrolyte to be 30 ° C ± 5 ° C, using a DC voltage stabilized power supply, in Under the condition of constant voltage 40V, anodizing treatment for 90min; wherein, the electrolyte is a mixed solution prepared by ammonium fluoride and ammonium sulfate with glycerol, ethylene glycol and deionized water as solvents, and the concentrations thereof are respectively 0.2 mol / liter and 0.2 mol / l;

[0047] Step 3: Rinse with deionized water and then dry naturally to obtain a surface-connected and surface-porous NiTi ...

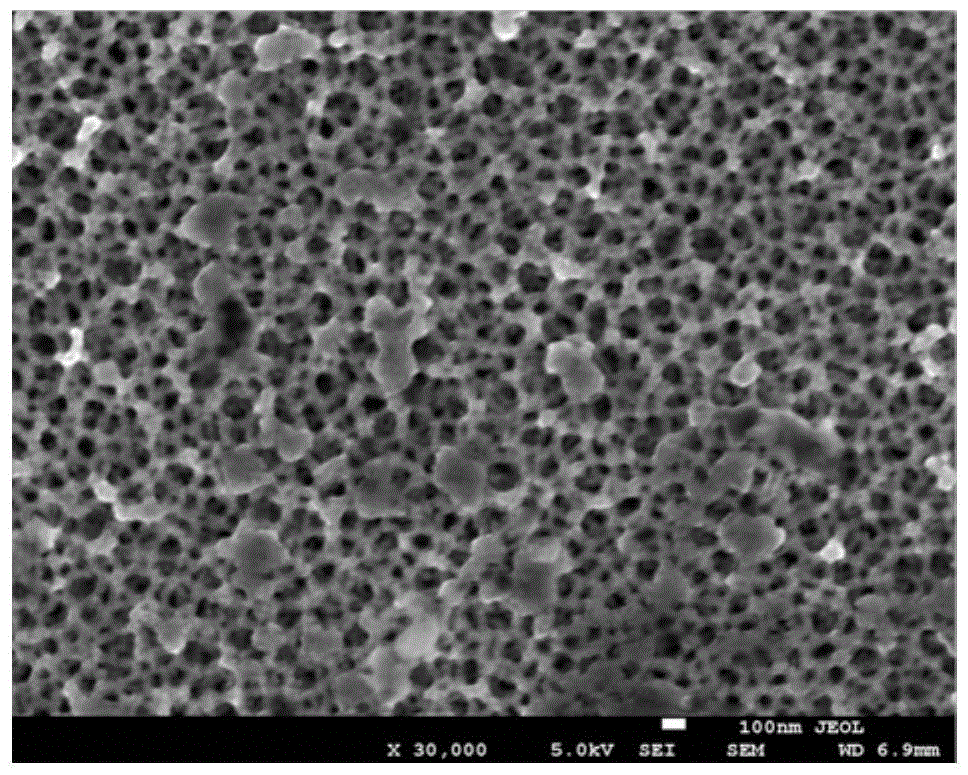

Embodiment 3

[0051] The surface of medical NiTi shape memory alloy was modified according to the following steps

[0052] Step 1: NiTi alloy surface pretreatment, followed by degreasing, SiC sandpaper grinding, mechanical polishing and ultrasonic cleaning;

[0053] Step 2: Anodizing treatment, put the NiTi alloy after ultrasonic cleaning into the electrolyte, use the NiTi alloy as the positive electrode, the graphite plate as the negative electrode, and control the temperature of the electrolyte to be 30 ° C ± 5 ° C, using a DC voltage stabilized power supply, in Anodizing treatment under the condition of constant voltage 50V for 90min; wherein, the electrolyte is a mixed solution prepared by ammonium fluoride and ammonium sulfate with glycerol, ethylene glycol and deionized water as solvents, and the concentrations thereof are respectively 0.1 mol / L and 0.2 mol / l;

[0054] Step 3: Rinse with deionized water and then dry naturally to obtain a surface-connected and surface-porous NiTi shap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com