A kind of resin control agent and preparation method thereof

A resin control agent and resin technology, which is applied in the field of pulp and paper making, can solve the problems of high speed of paper machines, hair loss, powder loss, and high requirements for paper, and achieve the effect of reducing broken ends, reducing negative impacts, and reducing energy consumption

Active Publication Date: 2017-01-25

天津市昌维生物科技有限公司

View PDF6 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The physical powder method needs to add more powder in the papermaking system. Due to the retention rate, some powder will always remain in the white water. Similarly, adding more powder to the paper will easily lead to hair loss and powder loss. and other negative phenomena

For the production of white paper, especially high-grade cultural paper or writing paper, the speed of the paper machine is high and the paper requirements are high. It is often difficult to meet the requirements by using traditional chemical methods, physical methods, and chemical-physical methods.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

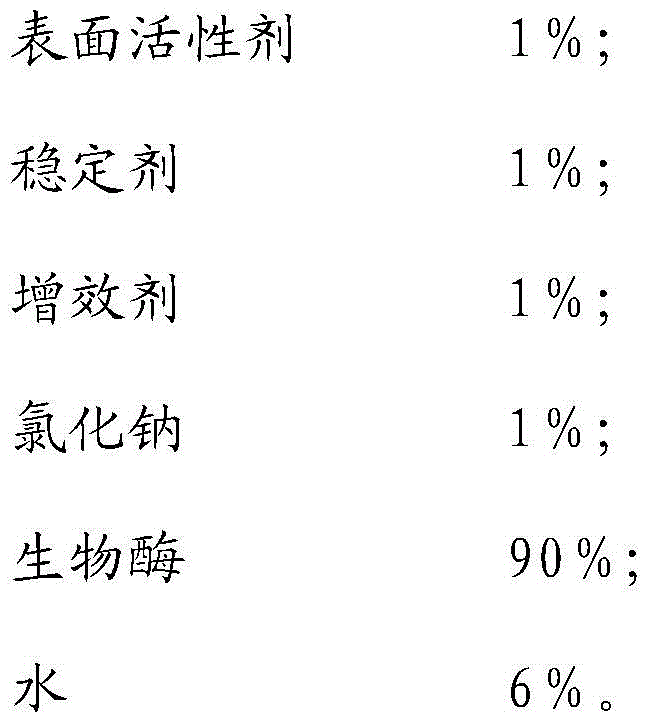

Embodiment 1

[0031]

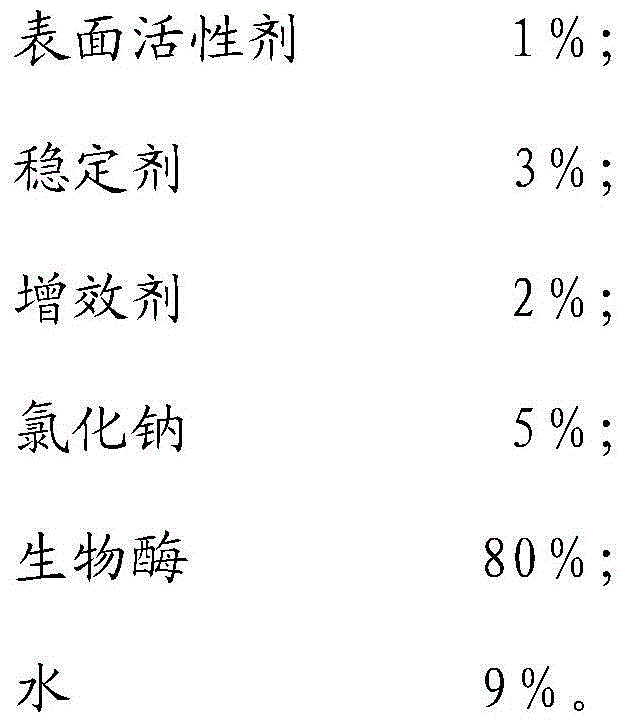

Embodiment 2

[0033]

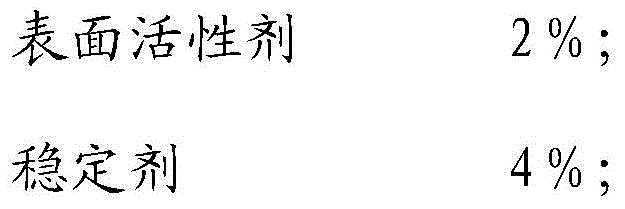

Embodiment 3

[0035]

[0036]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a resin control agent and a preparation method thereof. The resin control agent is composed of a surfactant, a stabilizing agent, a synergist, a biological enzyme and other compositions. Due to the fact that the resin control agent contains the biological enzyme composition, and a product obtained through compatibility of the resin control agent and other correlated compositions has strong pertinency, specificity and high efficiency. The compositions of the resin control agent does not contain any toxic nor harmful substances, the resin control agent is naturally degradable, and the product is strong in environment friendliness, is capable of reducing end breakage, paper breaking, net sticking, cylinder sticking phenomena and shutdown phenomenon all caused by resin in a production process, and is obvious in economic benefit. The resin control agent is easy to product and high in practicability.

Description

technical field [0001] The invention relates to the technical field of pulping and papermaking, in particular to a resin control agent used for resin purification treatment control in pulp and a preparation method thereof. Background technique [0002] Pulp is the main raw material for papermaking. Because the manufacture of pulp needs to consume a large amount of wood resources, in order to save wood resources and make full use of wood resources, the pulp yield is often increased as much as possible in the pulping process. The increase in pulp yield leads to more resins not being completely removed. Retained in the pulp; in addition, more and more fast-growing wood is used for the wood used in the current pulping raw materials. The use of fast-growing wood and the improvement of pulp yield have led to higher and higher resin content in pulp. The resin in the pulp is easy to cause abnormal production during the papermaking process, which is called resin barrier. For examp...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): D21H21/02D21H17/00

Inventor 陈彬蔡庭芳高威李志峰赵明

Owner 天津市昌维生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com