Composite turf of real grass and artificial grass and preparation method thereof

A technology of artificial grass and artificial grass silk, applied in botany equipment and methods, roads, gardening, etc., can solve the problems of artificial grass materials being difficult to degrade, artificial grass cannot absorb carbon dioxide, and poor effect, so as to reduce soil loss rate , It is beneficial to environmental protection and human health, and the effect of avoiding blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

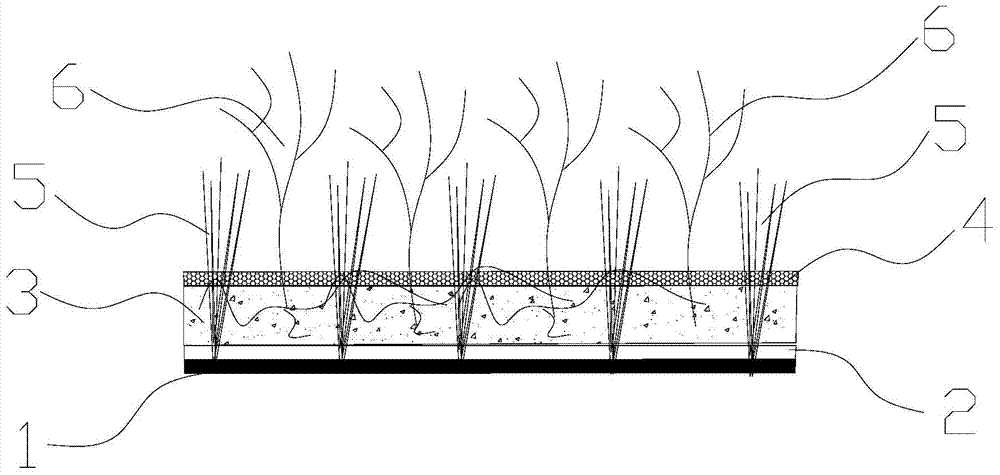

[0035] A composite turf of real grass and artificial grass, the composite turf comprises a base cloth 2, an adhesive layer 1, a soil layer 3, a mesh cloth 4, real grass 6 and artificial grass silk 5; the back of the base cloth 2 is compounded with Adhesive layer 1; the grid cloth 4, the soil layer 3, and the base cloth 2 are arranged sequentially from top to bottom; the artificial grass 5 is tufted on the base cloth 2, and the bottom of the artificial grass 5 is connected to the back The adhesive layer is bonded as one, and the top of the artificial grass 5 passes through the grid cloth 4; the grass root of the real grass 6 is located in the soil layer, and the stem of the real grass 6 passes through the grid cloth; The height of the artificial turf 5 is 50mm, the row spacing of the artificial turf 5 in the composite turf is 2 inches, and the number of stitches per meter is 150; 15mm circular grid; the grid is arranged in a plum blossom shape; the adhesive layer 1 is made of s...

Embodiment 2

[0044] A composite turf made of real grass and artificial grass, in which the angle between the cloth feeding direction of the cloth feeding machine and the horizontal direction in the preparation process is 0°, and the rest of the structure, parameters and preparation process are the same as those in Example 1.

Embodiment 3

[0046] A kind of composite turf of real grass and artificial grass, in its preparation process, the included angle between the cloth feeding direction of the cloth feeding machine and the horizontal direction is 5°, and the rest of the structure, parameters and preparation process are the same as those in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com