Sectional type oil drill pipe with seal structure

A sealing structure, oil drill pipe technology, applied in drill pipe, drill pipe, drilling equipment and other directions, can solve the problems of internal fluid leakage and poor sealing, so as to improve sealing performance, improve service life and prevent damage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

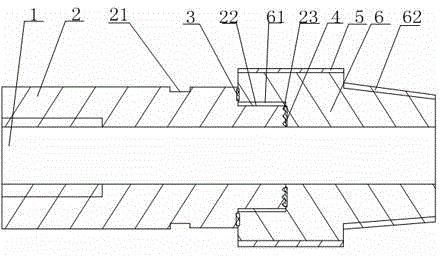

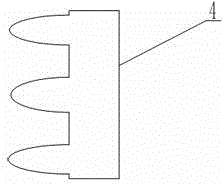

[0019] Such as figure 1 , figure 2 As shown, the segmented oil drill pipe with a sealing structure includes a main rod body 2 and a joint body 6, and a through hole 1 passing through the main rod body 2 and the joint body 6 is arranged inside the main rod body 2 and the joint body 6, and the main rod body 2 The outer wall is symmetrically provided with two flat grooves 21, the outer wall of the joint body 6 is also provided with a wear-resistant sleeve 5, one end of the main rod body 2 is provided with an external thread joint 22, and the inner wall of the other end is provided with an internal thread, and the outer diameter of the external thread joint 22 Smaller than the main rod body 2, one end of the joint body 6 is provided with an internally threaded joint 61 that cooperates with the externally threaded joint 22, and the other end is provided with a conical joint 62. The elliptical groove 23 is provided with a groove at the joint between the inner threaded joint 61 and...

Embodiment 2

[0022] This embodiment is on the basis of embodiment 1, as figure 1 , figure 2 As shown, the transition between the main rod body 2 and the external threaded joint 22 is provided with a stepped surface, and the stepped surface is provided with an annular groove that cooperates with the sealing ring 3, and the surface that matches the stepped surface at the end of the internal threaded joint 61 is also provided with a The ring groove I where the sealing ring 3 fits.

[0023] When the main rod body 2 is connected to the joint body 6, the cooperation of the annular groove, the annular groove I and the sealing ring 3 can well block the external and internal through-hole 1 of the oil drill pipe, and realize the sealing of the through-hole 1, so that the through-hole The working environment in 1 is not affected by the external space environment of the drill pipe.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com