Adjustment assembly for shock absorbing damping

A technology for adjusting components, shock absorption and damping, which is applied in the direction of shock absorbers, springs/shock absorbers, shock absorbers, etc. The motorcycle cannot adapt to the use environment and other problems, so as to achieve the effect of simple and compact structure, improved comfort and reliability, and satisfaction of driving habits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

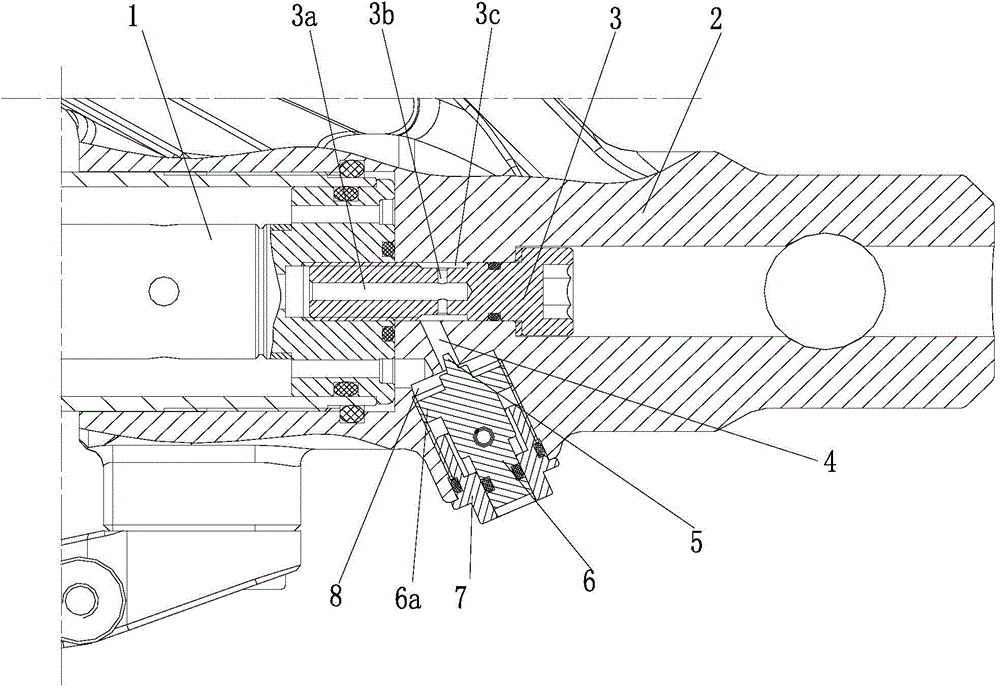

[0014] figure 1 It is a structural schematic diagram of the present invention, as shown in the figure: the adjustment assembly for shock absorption and damping in this embodiment, the damping force adjustment device includes an adjustment screw 6 and an adjustment cavity 8, and the adjustment cavity 8 passes through an adjustment channel 4 Connected to the damping chamber, the adjusting screw 6 drives a conical spool 5 to adjust the flow area of the regulating channel; the adjusting screw 6 drives the conical spool 5 to open, close or the adjustable part to open the regulating channel, during the adjustment process Changing the size of the adjustment chamber and the size of the flow area not only has high adjustment sensitivity, but also has linear characteristics to ensure the performance of the shock absorber; as shown in the figure, the conical valve core and the adjustment screw are integrally formed, and the adjustment chamber is formed in Between the front end of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com