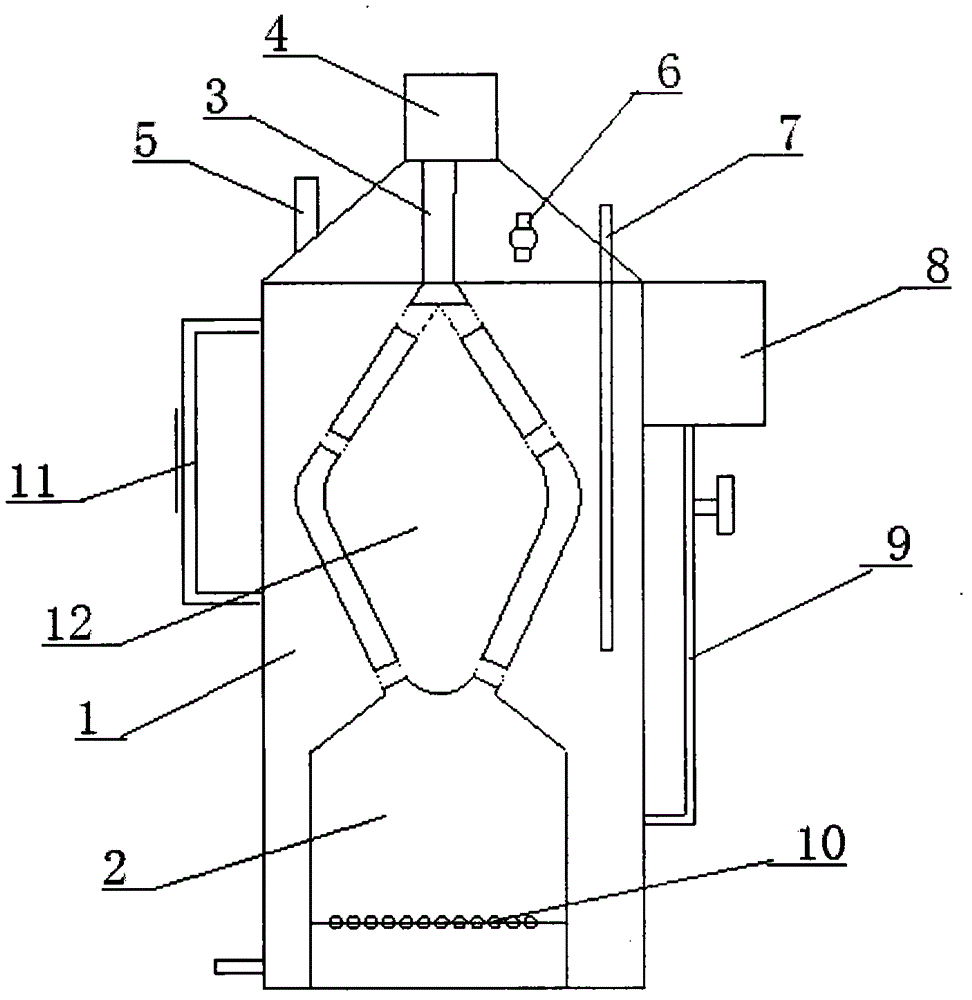

Steamer with double-cone liner

A steam pot and liner technology, which is applied in the field of steam pots, can solve the problems of low energy conversion rate and low heat conversion rate, and achieve the effect of large heating area and increased conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The technical solution of the present invention will be described in detail below in conjunction with the embodiments.

[0013] Such as figure 1 A steam boiler with a double-cone inner tank is shown, including a boiler 1, a fuel stove 2 inside the boiler 1, a water inlet pipe 9 and a water level gauge 11 on the side, a steam pipe 5, an air pressure valve 6 and a safety pipe 7 on the top , the inner smoke pipe 3 and the outer smoke port 4 arranged on the top of the boiler 1 also include a double-cone inner tank 12 on the fuel stove 2, whose long diagonal line is in the vertical direction, and the double-cone inner tank 12 passes through The pipe is connected to the boiler 1, and the inner smoke pipe 3 is on the double-cone inner tank 12. The radius of the inner smoke pipe 3 is smaller than the radius of the outer smoke port 4, and the safety pipe 7 goes deep into the boiler 1, and its depth is 1 of the height of the boiler 1. / 2, the outer wall of boiler 1 has insulatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com