A coupled air staging and fuel staging low nox four arch type w flame boiler

A fuel grading and air grading technology, which is applied in the combustion of multiple fuels, the combustion of gaseous fuels and powdered fuels, and the types of combustion, which can solve the problem that W-flame boilers cannot take into account emissions and efficient burnout at the same time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

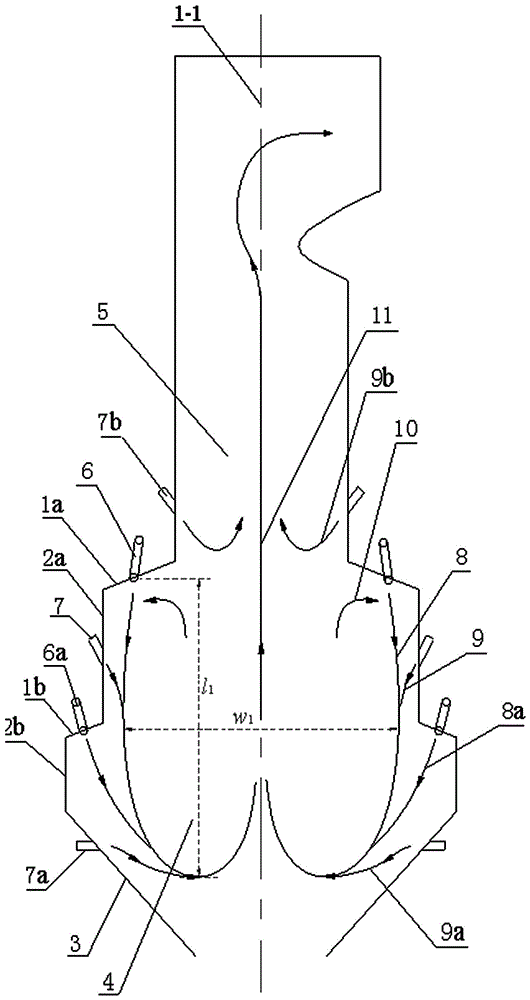

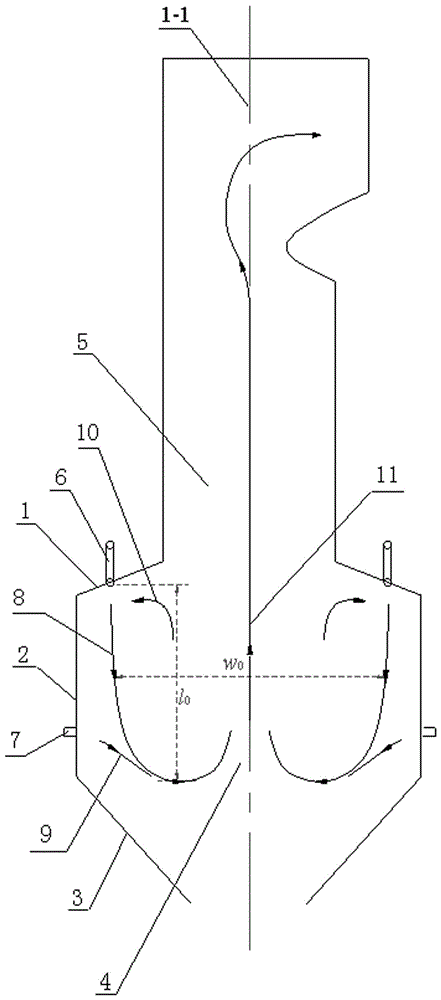

[0015] combine figure 1 Describe this embodiment, the four-arch type low NO that couples air staging and fuel staging of the present invention x The furnace of the W flame boiler is divided into two parts, the lower furnace 4 and the upper furnace 5. The lower furnace 4 is composed of the upper furnace arch 1a, the upper front and rear walls 2a, the lower furnace arch 1b, the lower front and rear walls 2b and the cold ash bucket 3; The powder burner 6 is arranged on the front and rear upper furnace arches 1a and communicates with the lower furnace 4 to feed the downwardly injected pulverized coal airflow 8; a plurality of graded air nozzles 7 are arranged in the middle of the upper front and rear walls 2a and It communicates with the lower furnace 4, and is used to introduce the classified air 9 to organize the classified combustion and carry the ignited pulverized coal airflow to continue downward; a plurality of superfine powder burners 6a are arranged on the front and rea...

Embodiment approach 2

[0019] combine figure 1 Describe this embodiment, the four-arch type low NO that couples air staging and fuel staging of the present invention x The pulverized coal burner 6 of the W flame boiler is inclined 5-15° outward relative to the vertical direction, the classified air nozzle 7 is inclined 45-60° downward relative to the horizontal direction, and the superfine powder burner 6a is inclined inward relative to the vertical direction Angle of 10~25°, cold ash hopper protection air spout 7a is tilted up 0~10° relative to the horizontal direction, overburning air spout 7b is tilted down 30~45° relative to the horizontal direction; pulverized coal flow 8, grading Wind 9, superfine powder jet 8a, cold ash hopper protection wind 9a and burn-off wind 9b all have wind speeds in the range of 40-60m / s. Other components and connections are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com