Trolley linkage structure of trolley-type thermal treatment furnace

A heat treatment furnace and connection structure technology, applied in the field of industrial furnaces, can solve problems such as high maintenance costs, difficulty in repairing wheel bearing drive gears, difficulty in separating two adjacent trolleys, etc., to achieve simple connection structure, reduce maintenance costs, and facilitate The effect of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

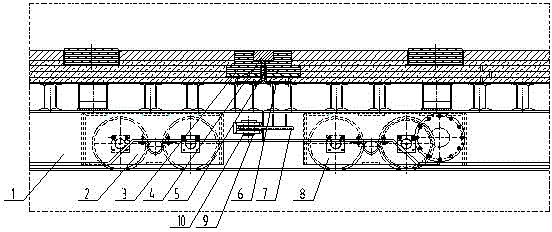

[0017] This embodiment discloses a trolley-type heat treatment furnace trolley connection structure used in the field of industrial furnaces. This structure can easily realize the separation of two adjacent trolleys, facilitate the replacement of trolley wheel bearings and gears, and greatly reduce the cost of the trolley. Repair costs for car bearings and gears.

[0018] Specifically, taking two adjacent trolleys as an example, the connection structure of trolley-type heat treatment furnace trolleys is as follows: figure 1 As shown, different from the integral structure of the upper masonry of adjacent trolleys, the frames of two adjacent trolleys in this embodiment are completely independent, that is, the frames of two adjacent trolleys are completely disengaged; There are two trolleys, the left side is the driven vehicle (the driven wheel pair 2 is arranged at the bottom), and the right side is the driving vehicle (the driving wheel pair 8 is arranged at the bottom).

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com