Vertical air spring fatigue testing machine

A technology of fatigue testing machine and air spring, which is applied in the testing of mechanical components, testing of machine/structural components, testing of material strength by applying repetitive force/pulsation force, etc. Reliability and other issues, to achieve the same amplitude, reliable test results, and remarkable energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

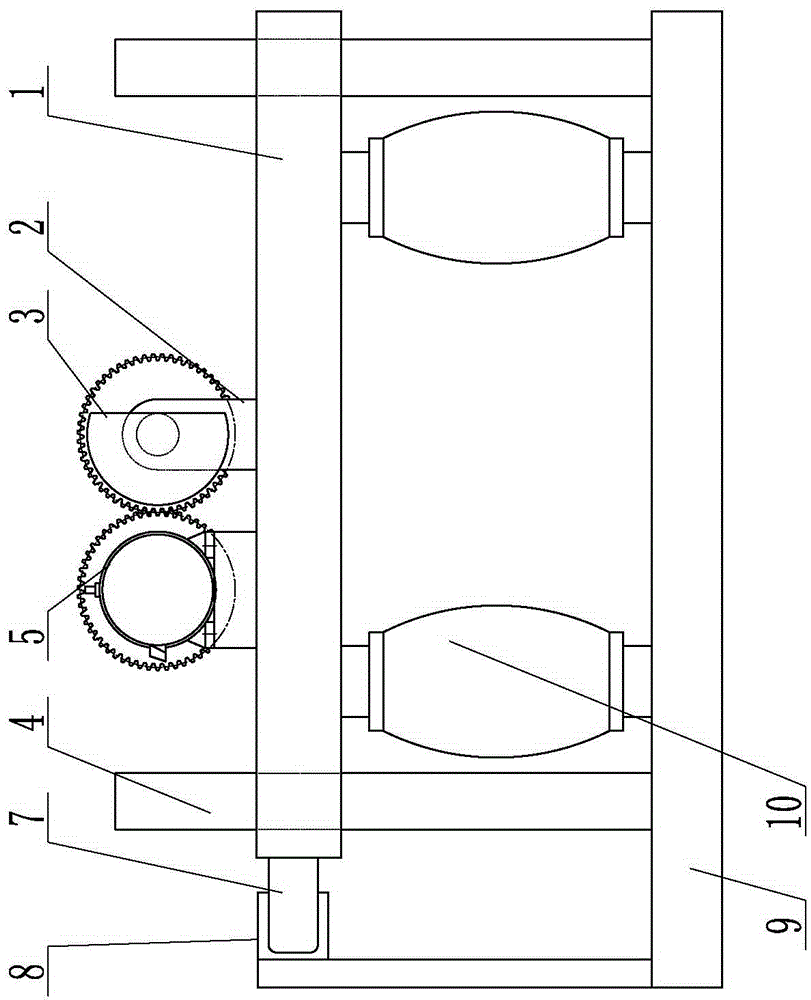

[0014] Description with reference to the accompanying drawings.

[0015] The plane on the base plate of the base 9 is horizontal, and two vertical guide rods 4 are fixedly connected to the plane on the base plate. In this embodiment, the driving power 5 is a servo motor, the motor base is fixedly connected to the sliding plate 1, and the servo motor is fixedly installed on the motor base. The servo motor drives the driving transmission gear to rotate, the driving transmission gear meshes with the driven transmission gear, and the eccentric roller 3 and the driven transmission gear are coaxially and fixedly installed together. The vertical eccentric roller support 2 is fixedly connected on the slide plate 1, the eccentric roller support 2 supports the eccentric roller 3 and the driven transmission gear, and the axes of the eccentric roller 3 and the driven transmission gear are horizontal. The axis of the eccentric roller 3 is installed at the center position of the slide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com