Pneumatic adjustable water resistor

A water resistance and adjustable technology, applied in the direction of liquid resistors, etc., can solve the problems of low operating efficiency, time-consuming and manpower consumption of high-power pulse devices, and achieve the effects of rapid adjustment, easy operation and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

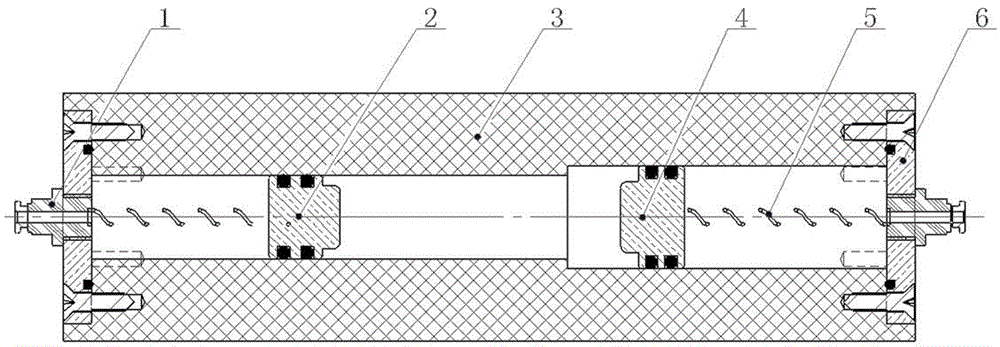

[0017] Such as figure 1 As shown, a pneumatically adjustable water resistor includes a resistor body 3, and the interior of the resistor body 3 is provided with a through hole axially penetrating the resistor body 3, and the through hole is composed of a small diameter through hole and a large diameter through hole connected in sequence. The aperture of the small-diameter through-hole is smaller than that of the large-diameter through-hole, and the electrode A2 that slides along the small-diameter through-hole and closely matches the inner wall of the small-diameter through-hole is installed in the small-diameter through-hole, and the electrode A2 is installed in the large-diameter through-hole. The electrode B4 slides along the large-diameter through hole and closely fits the inner wall of the large-diameter through hole. The electrode A2 and the electrode B4 are two cylinders with different diameters. The through hole between the electrode A2 and the electrode B4 is filled wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com