Device for changing cable between 35kV circuit straight rods and construction method

A linear rod and cable technology is applied in the field of devices for replacing cables between linear rods of 35kV lines, which can solve the problems of low operating temperature, affecting construction progress, and inconvenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

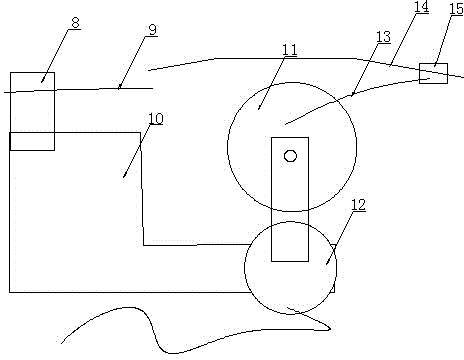

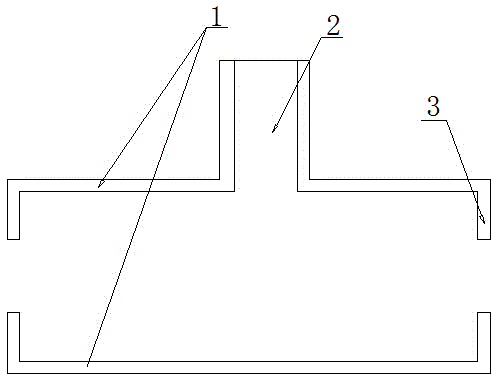

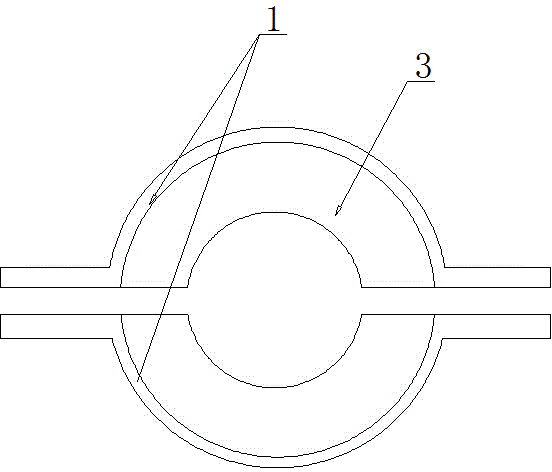

[0027] Embodiment 1: as figure 1 , 2 , 3, and 4, a device for replacing cables between straight rods of 35kV lines, including a cable tensioning mechanism, a cable connection mechanism and an injection molding insulation mechanism set on the cable connection mechanism, the cable tensioning mechanism includes a support 10. The fixed wire clamp 8 arranged on one side of the support 10, the reel 11 arranged on the other side of the support 10, the free end connected to the reel 11 has a stay rope 13 with a wire clamp 15, the reel 11 The drive motor 12 arranged on the support 10 is driven by a chain. The cable connection mechanism includes two symmetrical splints 7 fastened together by bolts 4. The splint 7 is provided with two symmetrical right-angled wires. Groove 6, the splint is provided with an injection molding groove 5 for connecting two right-angled wire grooves, the injection molding groove 5 is filled with tin liquid, and the injection molding insulation mechanism inclu...

Embodiment 2

[0042] Embodiment 2: as figure 1 , 2 , 3, and 4, a device for replacing cables between straight rods of 35kV lines, including a cable tensioning mechanism, a cable connection mechanism and an injection molding insulation mechanism set on the cable connection mechanism, the cable tensioning mechanism includes a support 10. The fixed wire clamp 8 arranged on one side of the support 10, the reel 11 arranged on the other side of the support 10, the free end connected to the reel 11 has a stay rope 13 with a wire clamp 15, the reel 11 The drive motor 12 arranged on the support 10 is driven by a chain. The cable connection mechanism includes two symmetrical splints 7 fastened together by bolts 4. The splint 7 is provided with two symmetrical right-angled wires. Groove 6, the splint is provided with an injection molding groove 5 for connecting two right-angled wire grooves, the injection molding groove 5 is filled with tin liquid, and the injection molding insulation mechanism inclu...

Embodiment 3

[0057] Embodiment 3: as figure 1 , 2 , 3, and 4, a device for replacing cables between straight rods of 35kV lines, including a cable tensioning mechanism, a cable connection mechanism and an injection molding insulation mechanism set on the cable connection mechanism, the cable tensioning mechanism includes a support 10. The fixed wire clamp 8 arranged on one side of the support 10, the reel 11 arranged on the other side of the support 10, the free end connected to the reel 11 has a stay rope 13 with a wire clamp 15, the reel 11 The drive motor 12 arranged on the support 10 is driven by a chain. The cable connection mechanism includes two symmetrical splints 7 fastened together by bolts 4. The splint 7 is provided with two symmetrical right-angled wires. Groove 6, the splint is provided with an injection molding groove 5 for connecting two right-angled wire grooves, the injection molding groove 5 is filled with tin liquid, and the injection molding insulation mechanism inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com