Electric brake device

A technology of electric braking and electric motor, applied in the direction of braking transmission device, braking action starting device, brake, etc., can solve problems such as controllability deterioration, and achieve the effect of improving controllability and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

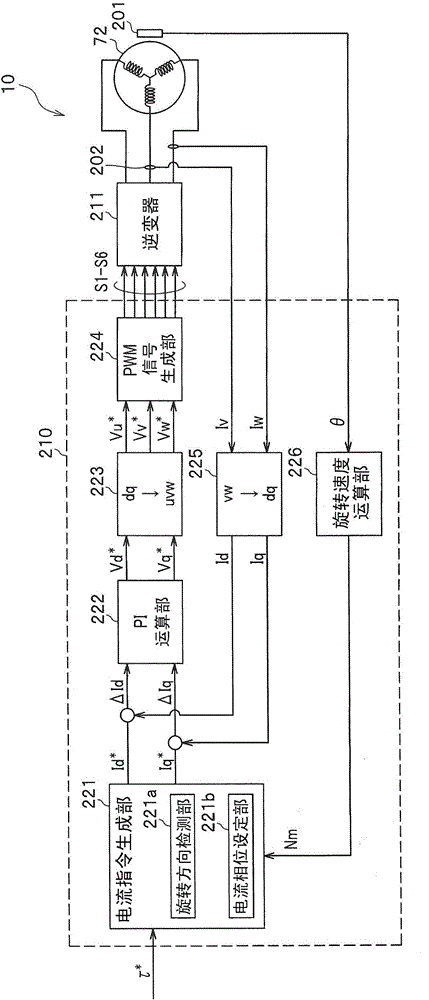

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

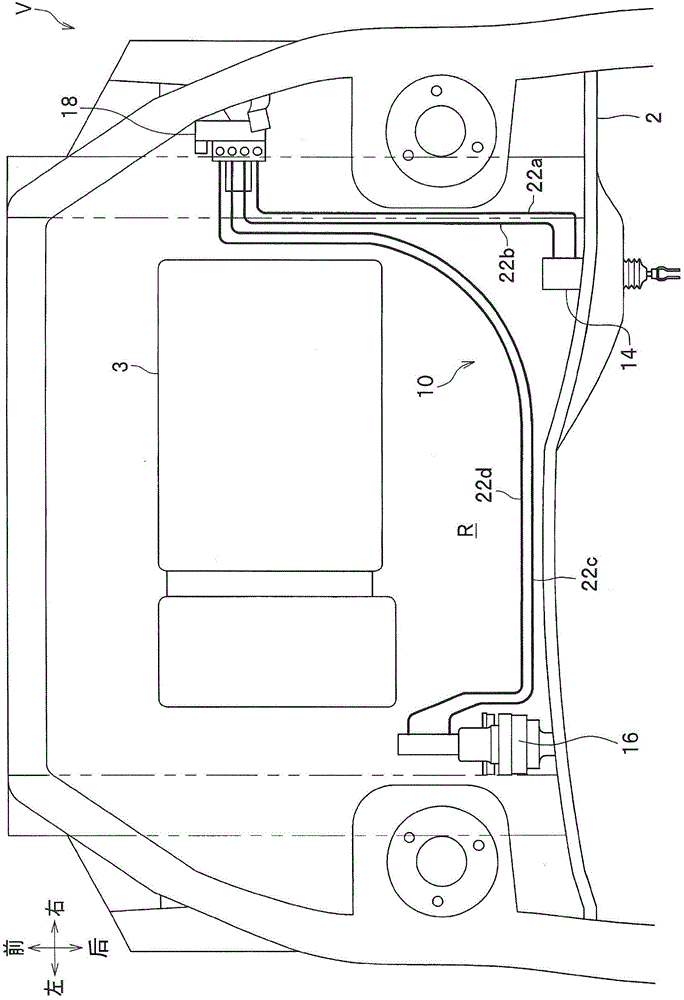

[0076] figure 1 It is a figure which shows the arrangement|positioning structure of the electric brake device of an embodiment of this invention on a vehicle. in figure 1 The arrows in the middle indicate the front, rear, left, and right directions of the vehicle V. The electric brake device 10 is installed so as to be mountable in various vehicles including, for example, a motor vehicle driven only by an engine (internal combustion engine), a hybrid vehicle, an electric vehicle, and a fuel cell vehicle.

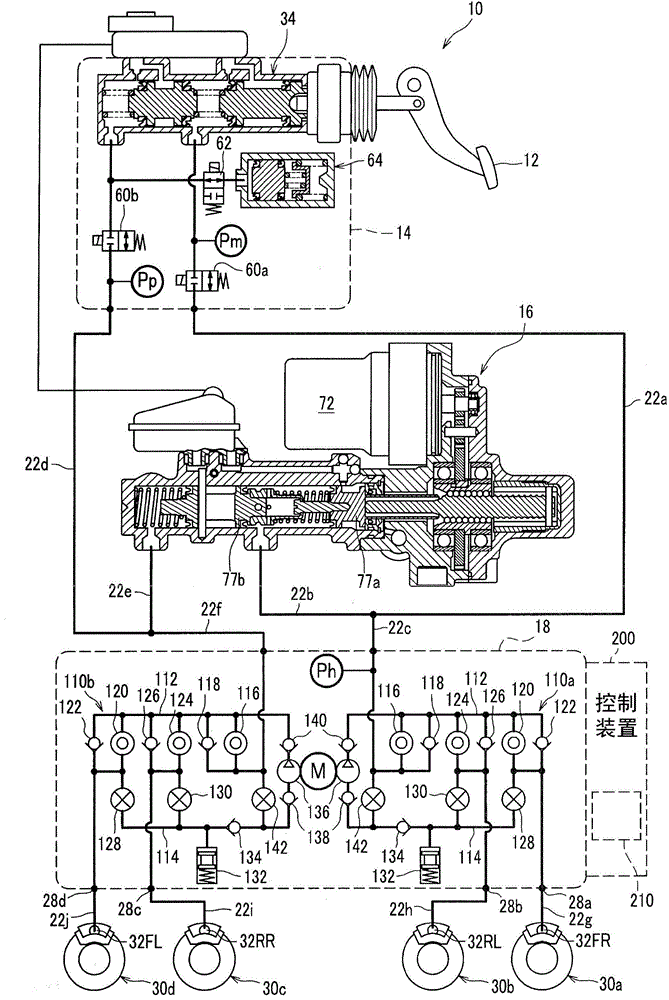

[0077] The electric brake device 10 provided with the vehicle stability assist device 18 (hereinafter referred to as the VSA device 18, VSA is a registered trademark) of the present embodiment has a By Wire brake system and a conventional hydraulic brake The system is composed of both of these systems. The brake-by-wire system is used for normal use to transmit electric signals to operate the brakes, and the hydraulic brake system is used for fail-safe conditions to transmit hy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com