Transparent vacuum pipeline

A vacuum pipeline and transparent technology, applied in the direction of roads, tracks, tunnel systems, etc., can solve the problems of economic loss of railway transport operators, difficult welding and construction, short replacement cycle, etc., to avoid engineering losses in hoisting, disassembly and replacement. The effect of reducing economic losses and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

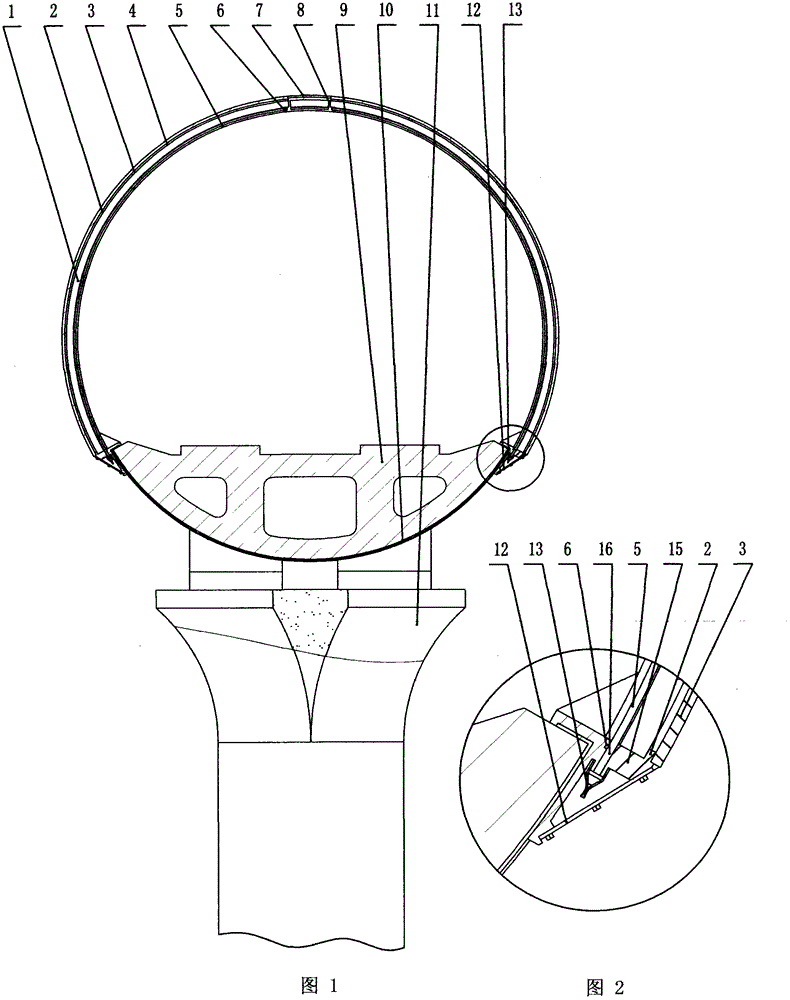

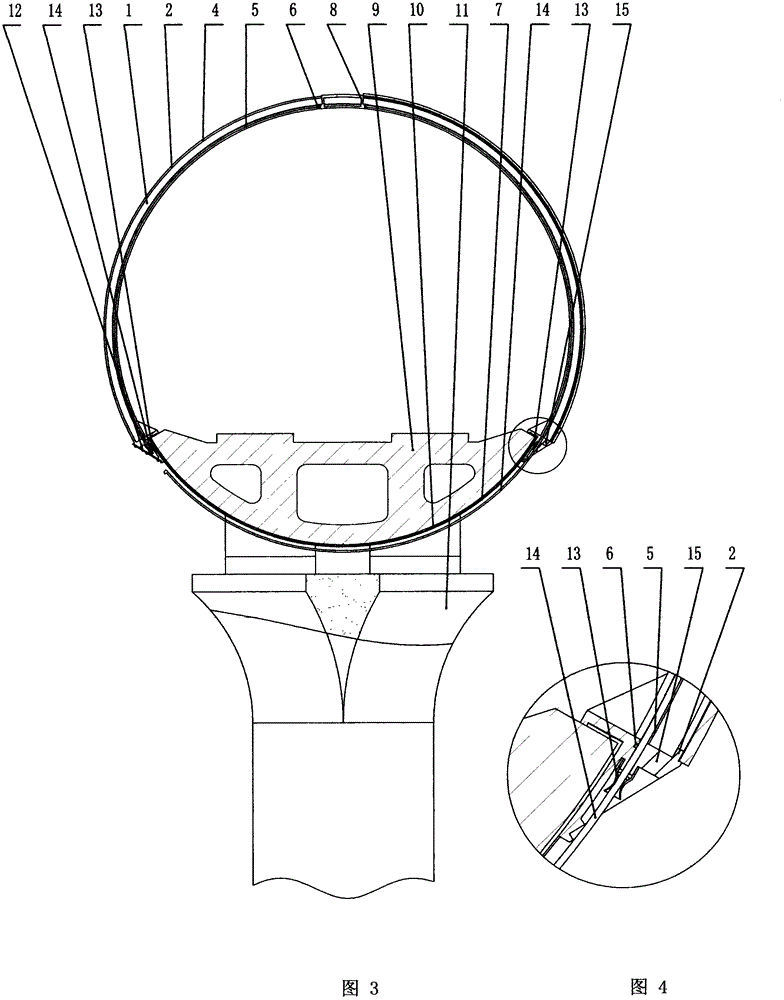

[0035] The present invention will now be described in further detail in conjunction with the accompanying drawings.

[0036] Now, a single-channel vacuum pipeline is used as an example to illustrate the technical points of the present invention.

[0037] like figure 1 As shown, the bottom of the vacuum duct includes a rail foundation 9 , which is wrapped with a foundation sealing plate 10 to seal the rail foundation 9 . The vacuum pipeline usually adopts an elevated structure and is supported by the support column 11 .

[0038] The track foundation 9 of the present invention is provided with a support frame 1 , both sides of the support frame 1 are arc-shaped, the whole is arch-shaped, and supported on both sides of the base sealing plate 10 . The outer layer of the support frame 1 is provided with an outer support rib plate 2, the outer part of the outer support rib plate 2 is tightly connected to the pipeline sealing plate 3, and the outer supporting rib plate 2 and the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com