Spool for spinning machine

A technology for textile machinery and reels, which is applied in the field of reels for textile machinery, can solve the problems of inability to meet modern large-scale production, difficulty in winding, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

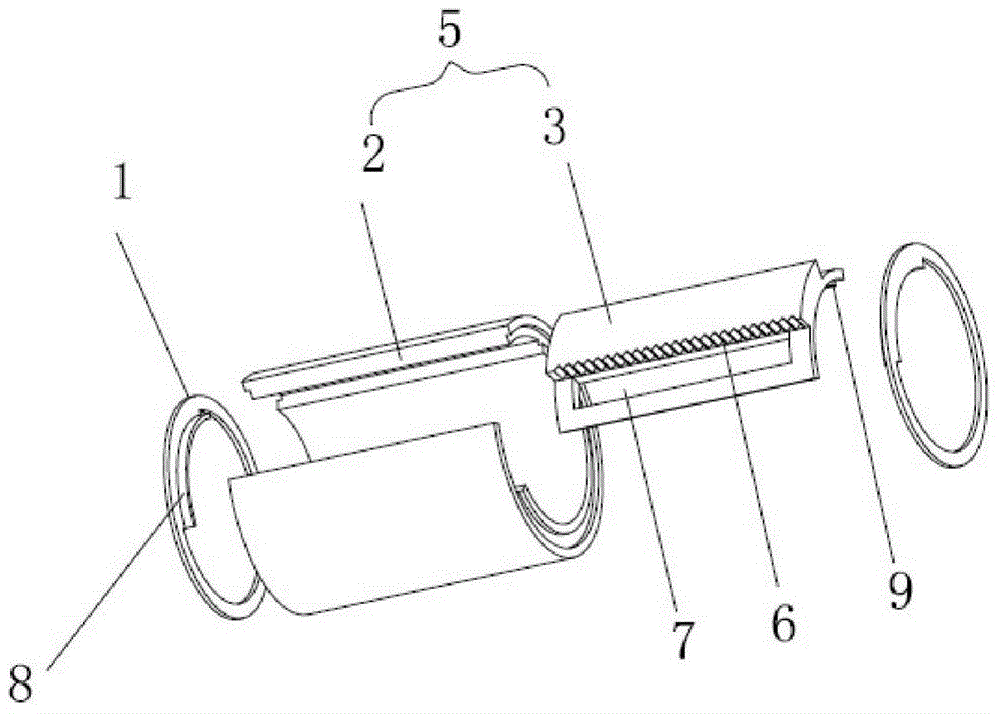

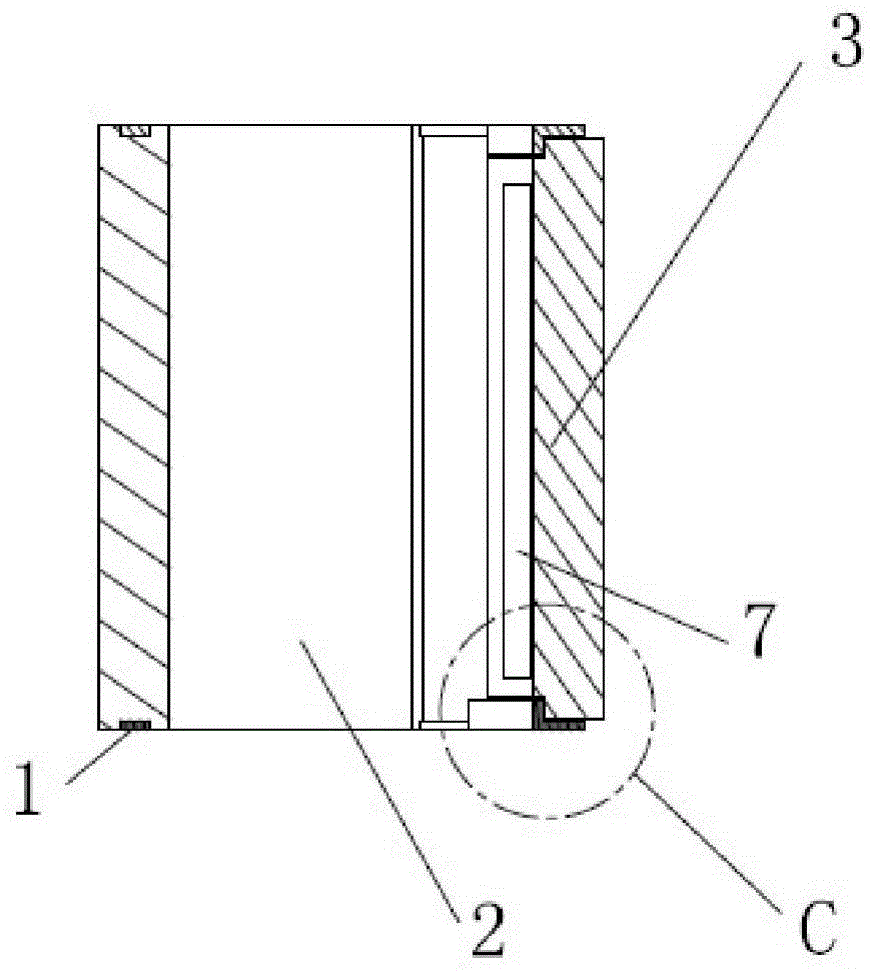

[0021] Attached below Figures 1 to 5 The technical solutions of the present invention are further described through specific implementation methods.

[0022] A reel for textile machinery, comprising a reel assembly 5 and retaining rings 1 arranged at both ends of the reel assembly 5, the reel assembly 5 includes a reel 2 and a slider 3, the circumference of the reel 2 An opening is arranged on the surface axis, and the opening is matched with the slider 3, and the slider 3 slides left and right along the inner circumferential surface on both sides of the opening, and the two ends are provided with the retaining ring 1 to match. Step 9. When winding the cloth, the slider can insert the cloth head into the long hole between the slider and the reel to accommodate the cloth head, and then push the slider to the side of the reel to firmly clamp the cloth through the zigzag stripes Tight, and the slider will not fall off when the reel is removed, which is convenient, quick, time-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com