Method for continuous production of 2-chloro-5-methylpyridine

A picoline and production method technology, applied in the field of continuous production of 2-chloro-5-picoline, can solve the problems of small production capacity, high cost, low production efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

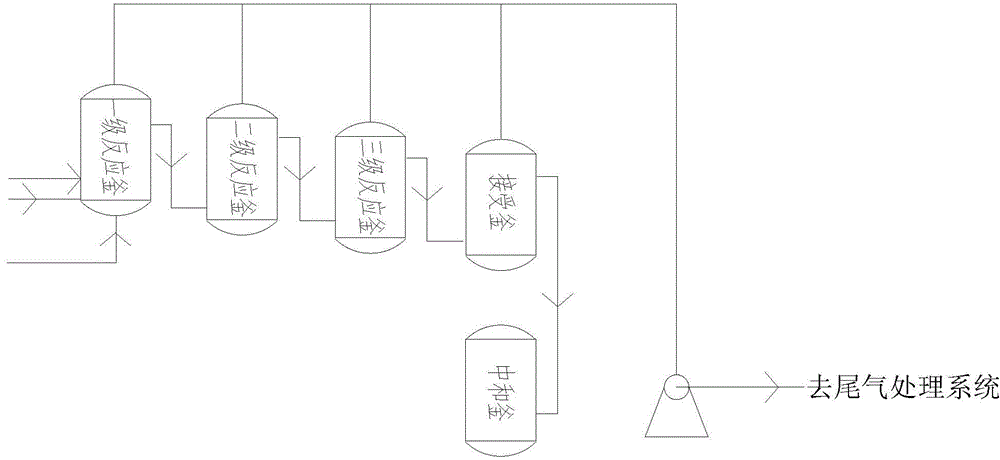

Image

Examples

Embodiment 1

[0011] Add toluene of 1 / 10 of the volume of the container into the first, second, and third-stage mixing reactors, raise the temperature in the first, second, and third-stage reactors to 30°C, and control the pressure in the first-stage reactors to -1000kPa; 2-Chloro-4-formyl valeronitrile, phosphorus trichloride, and toluene are transported to the first-stage tank-type mixed reactor for reaction through metering pumps 1, 2, and 3 at a volume ratio of 1:0.1:0.01, and then passed through the overflow In the form of flow, it goes to the two-stage tank reactor, the three-stage tank reactor, and the receiving tank for continuous reaction, and finally adds alkali to the neutralization tank to adjust the pH of the system to be greater than 7 to obtain crude 2-chloro-5-picoline , and its yield to 2-chloro-4-formylvaleronitrile was 75%.

Embodiment 2

[0013] Add 1 / 10 of the container volume of chlorinated benzene to the first, second, and third-stage mixing reactors, raise the temperature in the first, second, and third-stage reactors to 120°C, and control the pressure in the first-stage reactors to +1000kPa ; 2-chloro-4-formyl valeronitrile, phosphorus pentachloride, and chlorinated benzene are delivered to the first-stage tank-type mixed reactor by metering pumps 1, 2, and 3 in a volume ratio of 1:10:10 for reaction , and then proceed to the secondary tank reactor, the three-level tank reactor, and the receiving tank in the form of overflow for continuous reaction, and finally add alkali to the neutralization tank to adjust the pH of the system to be greater than 7 to obtain crude 2-chloro- 5-Methylpyridine with a yield of 79% to 2-chloro-4-formylvaleronitrile.

Embodiment 3

[0015] Add 1 / 10 of the volume of benzene in the first, second, and third-stage tank-type mixed reactors, raise the temperature in the first, second, and third-stage stills to 70°C, and control the pressure in the first-stage still to 0kPa; -Chloro-4-formylvaleronitrile, phosphorus oxychloride, and benzene are transported to the first-stage tank-type mixed reactor for reaction through metering pumps 1, 2, and 3 at a volume ratio of 1:0.3:1, and then through the overflow in the form of two-stage tank reactor, three-stage tank reactor, and receiving tank for continuous reaction, and finally add alkali to the neutralization tank to adjust the pH of the system to be greater than 7 to obtain crude 2-chloro-5-picoline , and its yield to 2-chloro-4-formylvaleronitrile was 90.2%.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap