Electrical bare wire continuous heater and method for controlling the same

A continuous heater technology, used in water heaters, fluid heaters, electric heating devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

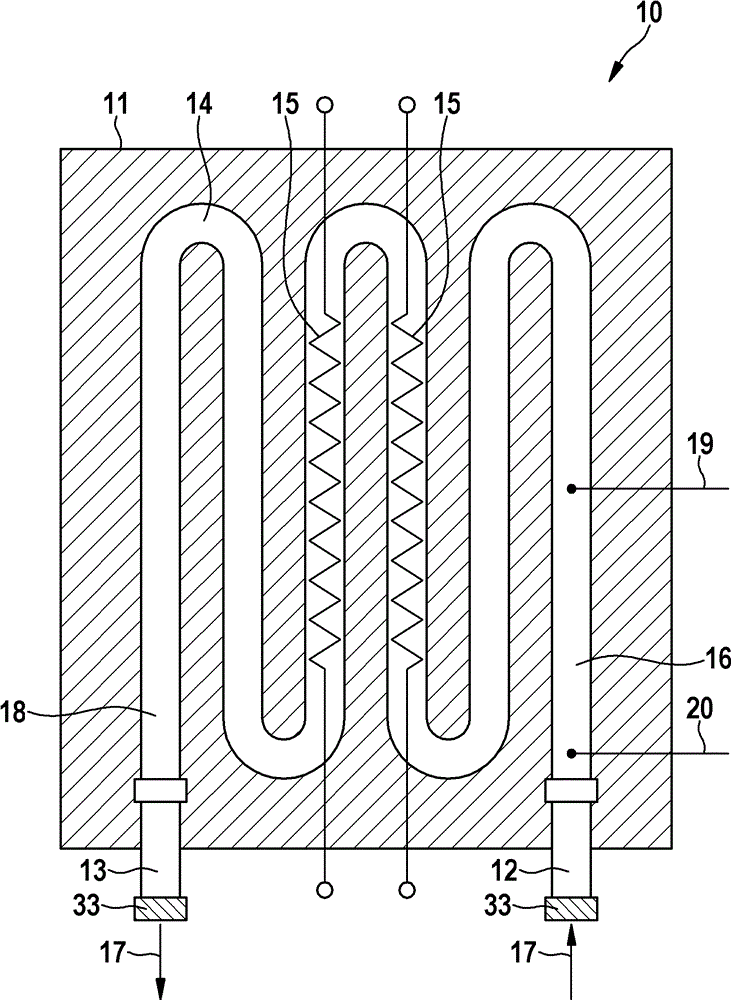

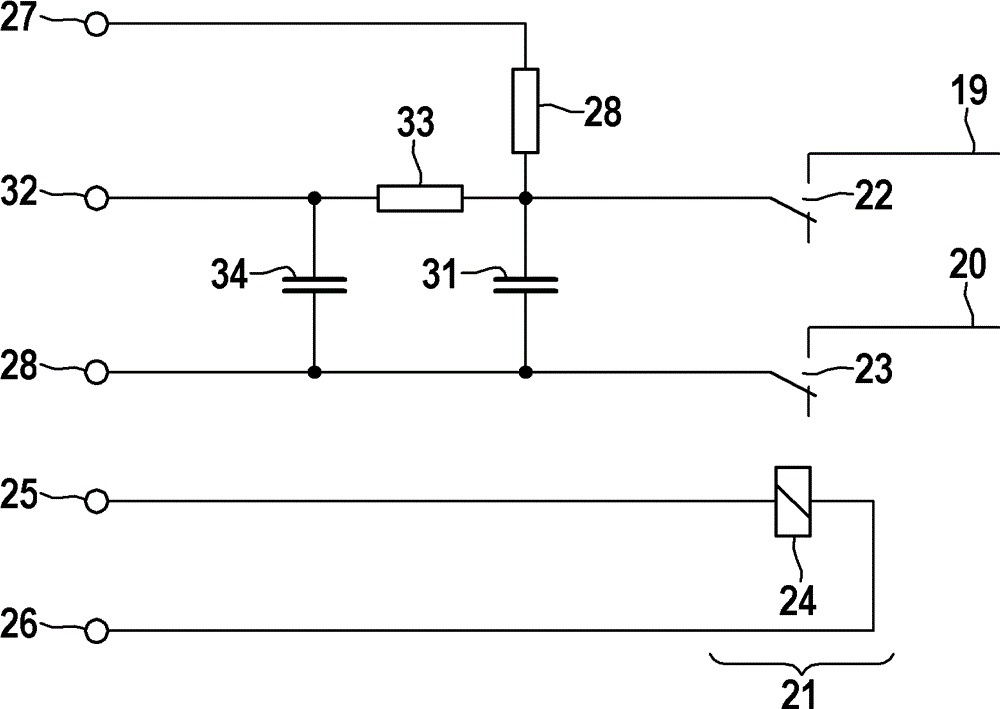

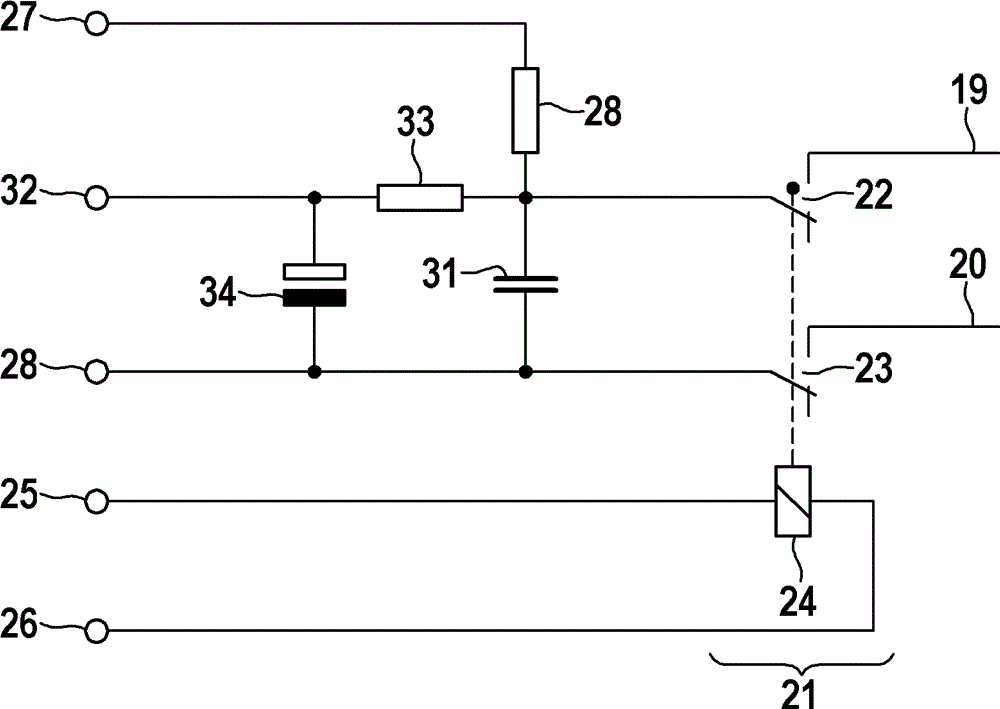

[0028] exist Figures 1 to 6 The bare wire continuous heaters 10 according to the present invention are schematically shown in respectively. The bare wire continuous heater 10 includes a channel assembly 11 . The channel assembly 11 includes a water inlet channel 12 and a water outlet channel 13 . The water inlet channel 12 is set up to be connected to an external (not shown in the figure) first water line for supplying water, while the water outlet channel 13 is set up to be connected to an external (also not shown in the figure) outlet The second water pipeline of water. In other words, the water inlet channel 12 is used for the inflow of water to be heated, while the water heated in the bare-wire continuous heater 10 is withdrawn or conducted out of the water outlet channel 13 . The water inlet channel 12 and the water outlet channel 13 are preferably electrically conductive, for example made of an electrically conductive metal, and are each electrically conductively con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com