Rare-earth high-iron aluminum alloy environment-friendly nano-fire-insulated fire-resistant cable

A nano fire-proof and fire-resistant cable technology, applied in the direction of nanotechnology, nanotechnology, insulated cables, etc., can solve the problems of mechanical properties that cannot meet the requirements, affect the service life of cables, conductor temperature heating and creep, etc., to alleviate the scarcity of copper resources , Simple structure, good non-corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

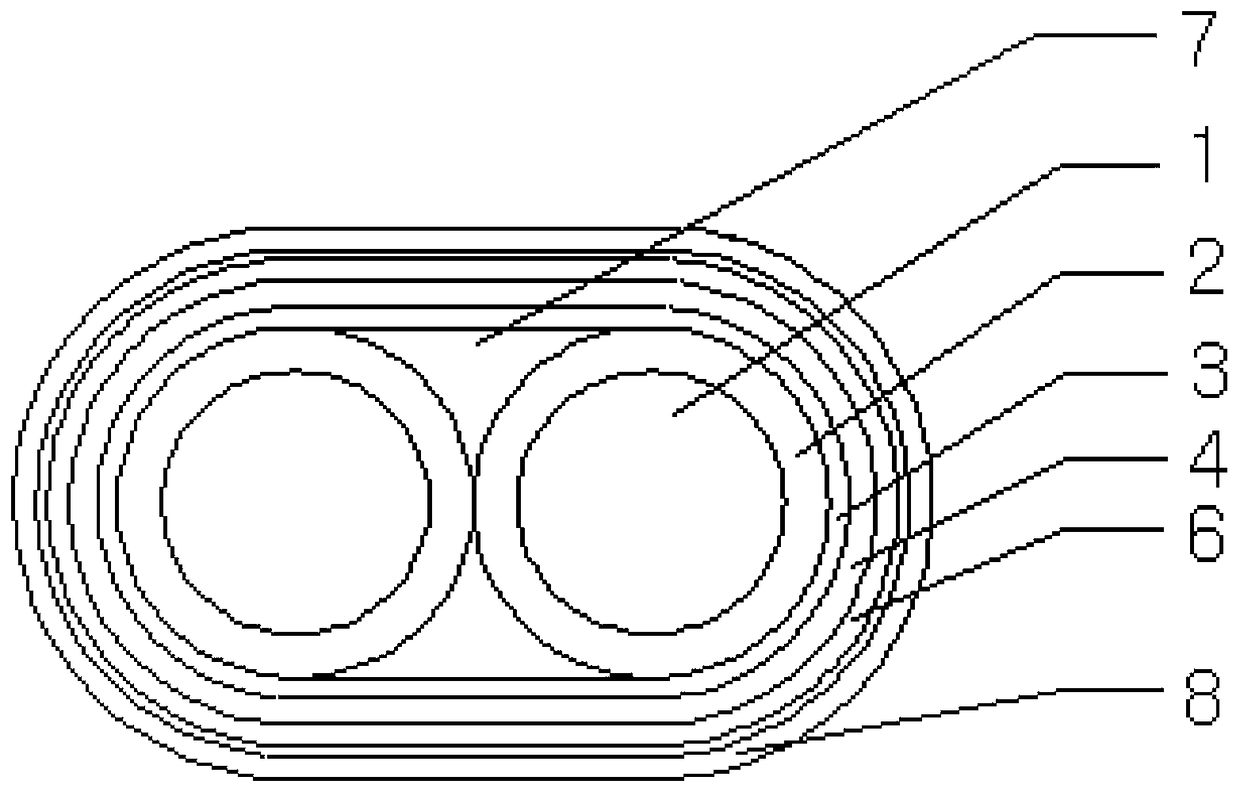

[0039] Such as figure 1 As shown, the main body of the cable is provided with two cable cores, and the two cable cores both have a structure in which the conductor core 1 is covered with an insulating layer 2 . The cross-sections of the two cable cores are arranged in a straight line, and the inner isolation layer 3 is wrapped around the outside of the two cable cores arranged in bundles. The inner isolation layer 3 and the insulating layer 2 have a double insulation protection effect on the conductor core 1 . Between the inner isolation layer 3 and the insulating layer 2 is filled with an environmentally friendly fire-proof filler 7, and the outside of the inner isolation layer 3 is covered with a self-locking armor protection layer 4, and a composite The environment-friendly nano fire-proof layer 6 and the composite environment-friendly nano-fire-proof layer 6 are provided with a flame-retardant protective layer 8 outside.

Embodiment 2

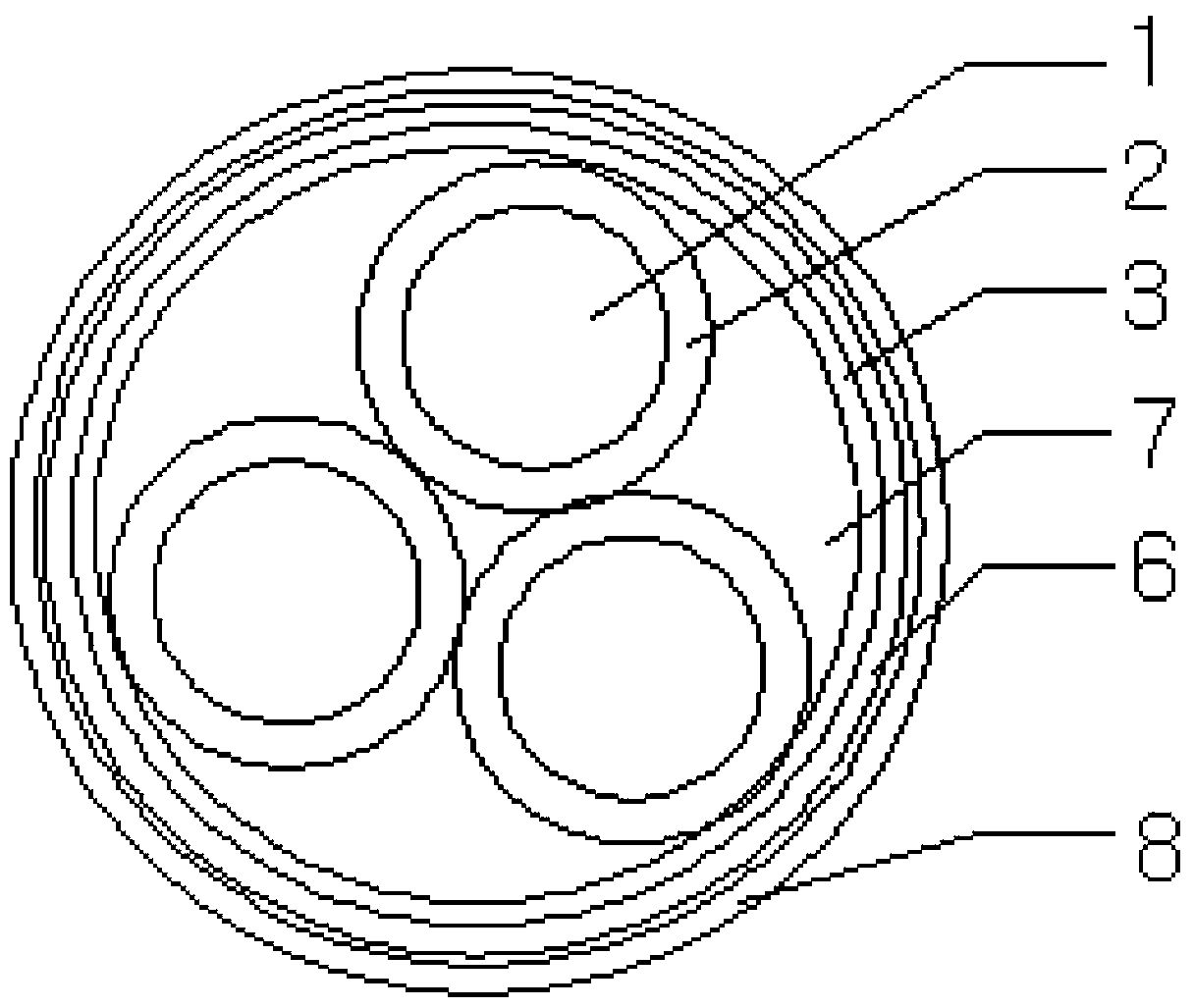

[0041] Such as figure 2As shown, the main body of the cable is provided with three cable cores, and the three cable cores all have a structure in which the conductor core 1 is covered with an insulating layer 2 . The cross-sections of the three cable cores are arranged in the shape of a square, and the inner isolation layer 3 is wrapped around the outside of the three cable cores arranged in bundles. The space between the inner isolation layer 3 and the insulating layer 2 is filled with an environmentally friendly fire-proof filler 7, and the inner isolation layer 3 is provided with a composite environmental protection nano-fire insulation layer 6, and the exterior of the composite environmental protection nano-fire insulation layer 6 is provided with flame-retardant protection. Layer 8.

Embodiment 3

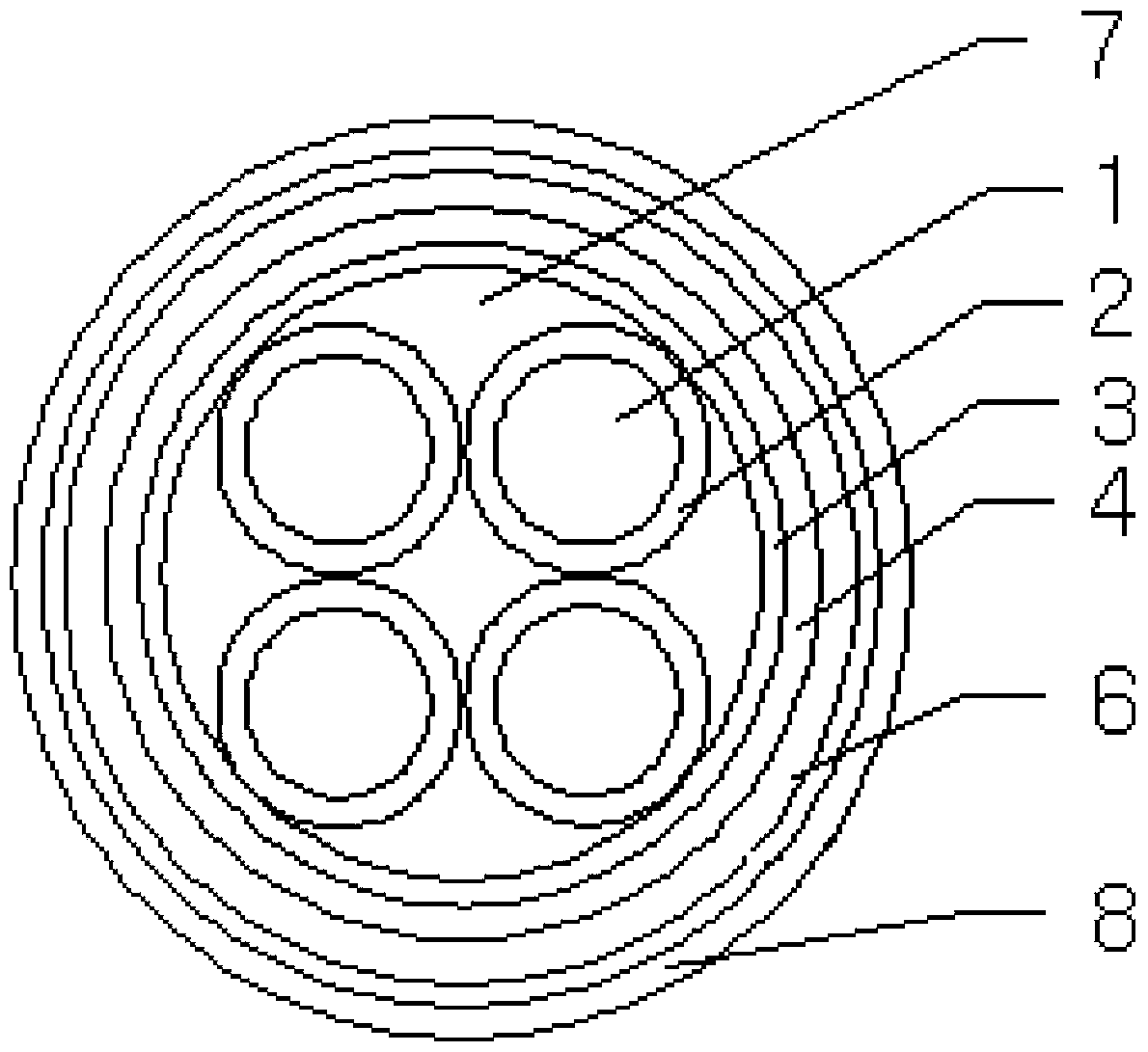

[0043] Such as image 3 As shown, the main body of the cable is provided with four cable cores, and the four cable cores all have a structure in which the conductor core 1 is covered with an insulating layer 2 . The cross-sections of the four cable cores are arranged in a square shape, and the inner isolation layer 3 is wrapped around the outside of the four cable cores arranged in bundles. An environment-friendly and fireproof filler 7 is filled between the inner isolation layer 3 and the insulating layer 2 . The inner isolation layer 3 adopts an embossed high-strength flame-retardant belt provided with a fiber band to improve the overall strength and flexibility of the inner isolation layer, and the arrangement of the fiber band can improve the fire resistance of the inner isolation layer. A flame-retardant protective layer 8 is provided on the outside of the composite environmental protection nano-fire-proof layer 6, and the composite environmental-friendly nano-fire-proof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com