Medium-frequency heating device for end parts of steel bar and steel pipe

A heating device and steel pipe technology, applied in induction heating devices, induction heating and other directions, can solve the problems of labor and time-consuming, long test period, etc., and achieve the effect of low technical requirements and prevention of sharp angle effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

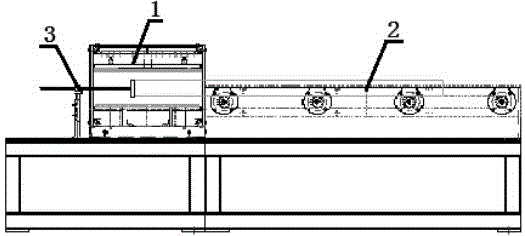

[0014] This embodiment is aimed at an intermediate frequency heating device at the end of a steel rod and steel pipe, which consists of three parts: an induction device 1 , a feeding device 2 , and a cooling device 3 .

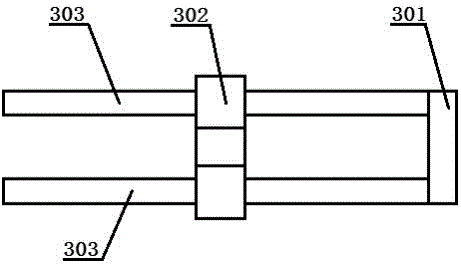

[0015] The cooling device 3 includes a ring pipe 301, an inlet and outlet pipe 302, and a bracket 303. The ring pipe 301 is fixed on one end of the inlet and outlet pipe 302 by welding, and the inlet and outlet pipe 302 is fixed on the top of the bracket 303. The ring pipe 301 and the inlet and outlet pipes 302 are all for hollow tubes.

[0016] The sharp corner effect of intermediate frequency heating at the end of steel rod and steel pipe is very common, because the head has sharp corners, the magnetic lines of force passing through the sharp corners are dense, the induced current density is large, and the induction heating s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com