Process for making double-layer bottle/cup

A production process, double-layer technology, applied in the field of bottle cup production process with double-layer structure, can solve the problems of easy harm to infants, failure to achieve safety, injury, etc., achieve simple and easy overall process, and improve use safety , enrich the effect of models and shapes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Example one, such as Figure 1 ~ Figure 6 Shown:

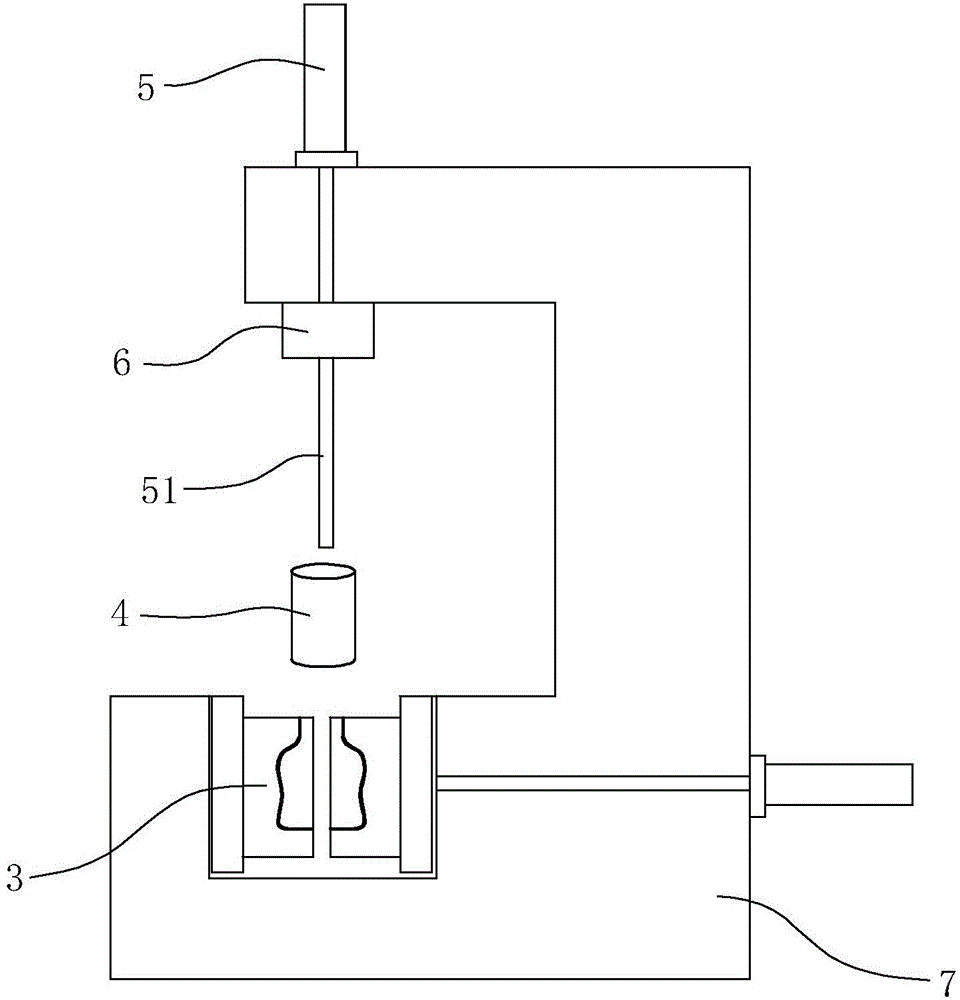

[0039] The first embodiment discloses a manufacturing process of a double-layer bottle cup. The manufacturing process specifically includes the following steps:

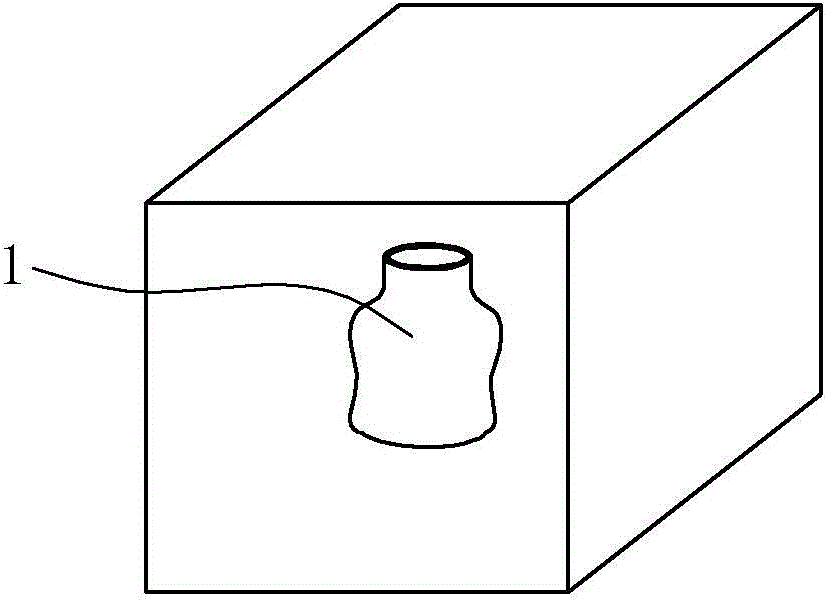

[0040] Step 1: Make a single-layer outer preform 1 which can be made of plastic or glass material. The outer preform 1 has an open mouth.

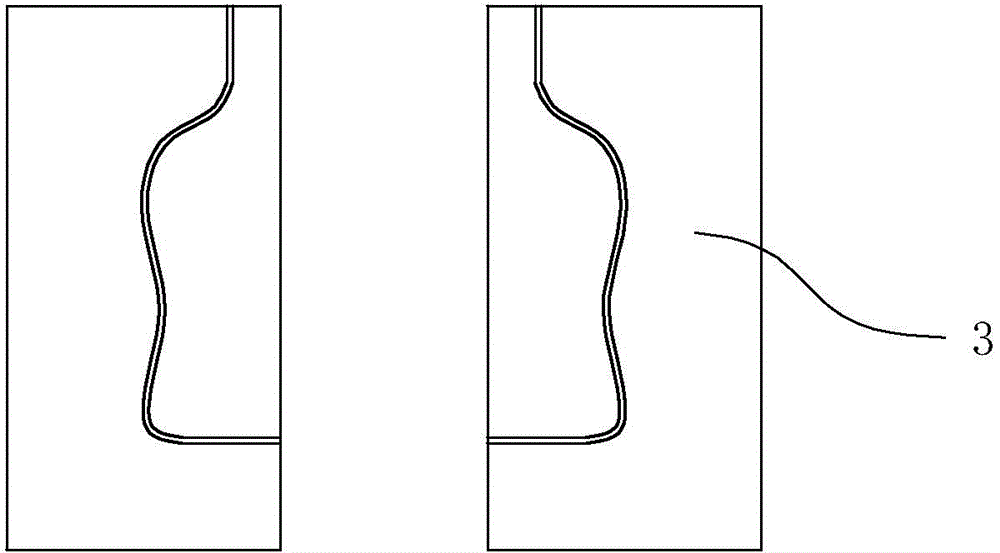

[0041] Step 2. Make a concave mold 3 with the same size as the outer preform 1 in step 1. The concave mold 3 can be made by casting silicone rubber as a fixed mold for the outer preform 1; the concave mold 3 is specifically made The process is as follows:

[0042] (1) Brush the release agent on the outer surface of the outer preform 1, while fixing the outer preform 1 and placing it in the middle of the mold;

[0043] (2) After mixing the silicone rubber with a chain extender and a vulcanizing agent in a ratio of 1:1, vacuum degassing is carried out. Among them, the chain extender is preferably methyl vinyl bispyrrolidone silane, ...

Embodiment 2

[0061] Example two, such as Figure 7 , Figure 8 Shown:

[0062] The manufacturing process of the double-layer preform of the second embodiment and the first embodiment is exactly the same, the difference is that the outer preform 1'used in the second embodiment is a double-ended baby bottle with a bottle opening at the upper and lower ends. The small hole 11' of the outer preform 1'is opened on the outer surface of one side of the bottle mouth, see Figure 7 Since the outer preform 1'is directly used as a model, the blowing of the inner preform 2'does not require additional molds, and a more complex bottle shape can be made, which is compared with the common ones in the prior art The straight cylindrical bottle cup, the manufacturing process adopted in this embodiment can enrich the model and appearance of the product, meet the use needs of users with different functions, and have a broader practical prospect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com