Blanking device for centrifuge

A centrifuge and feeding tube technology, applied in the centrifuge and other directions, can solve the problems of dryer or silo blockage, inconvenient adjustment, uneven discharge, etc., and achieve the effects of improving sealing, convenient cleaning, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

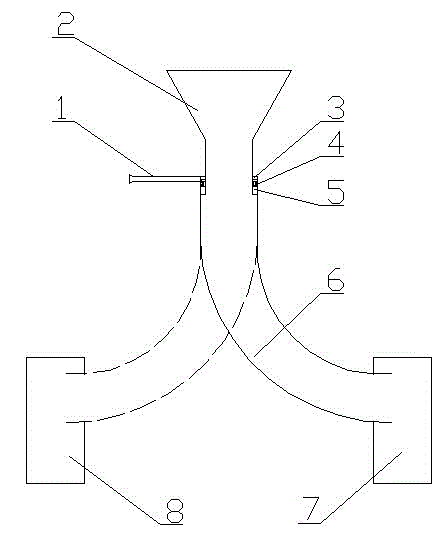

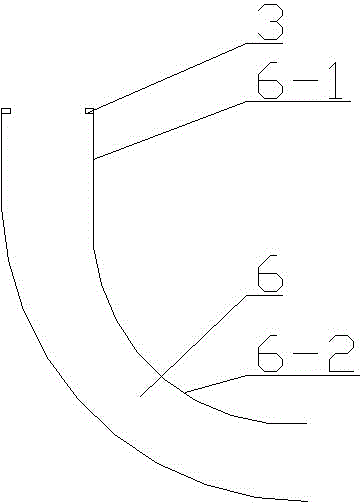

[0023] refer to figure 1 , image 3 with Figure 4 , a centrifuge blanking device, comprising a hopper 2, a blanking tube 6, a blanking tube fixing mechanism, a position adjustment handle 1, a sealing ring 4, a first discharge cylinder 7 and a second discharge cylinder 8; The upper end of the feeding pipe 6 is movably connected to the lower end of the hopper 2 through the fixing mechanism of the feeding pipe; the joint between the feeding pipe 6 and the hopper 2 is provided with a sealing ring 4; The adjustment handle 1 of the feeding pipe 6; the feeding pipe 6 is composed of a circular steel pipe 6-1 and an arc-shaped hose 6-2; the end of the arc-shaped hose 6-2 is located at the first discharge barrel 7 or in the second discharge barrel 8, so that the material in the curved hose 6-2 enters the first discharge barrel 7 or the second discharge barrel 8 at a tangent; the first discharge barrel 7 or the second discharge barrel A notch 7-1 for placing an arc-shaped hose 6-2 is...

Embodiment 2

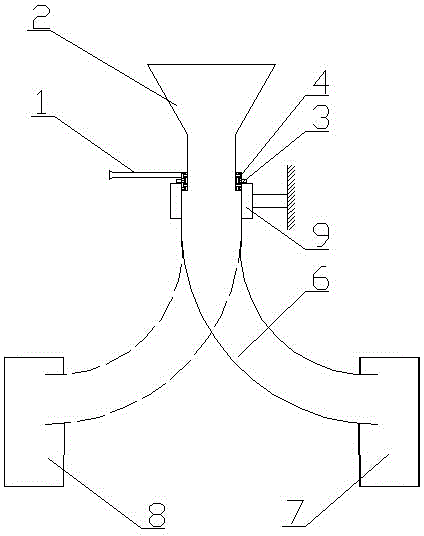

[0028] refer to Figure 2~4 , a centrifuge blanking device, comprising a hopper 2, a blanking tube 6, a blanking tube fixing mechanism, a position adjustment handle 1, a sealing ring 4, a first discharge cylinder 7 and a second discharge cylinder 8; The upper end of the feeding pipe 6 is movably connected to the lower end of the hopper 2 through the fixing mechanism of the feeding pipe; the joint between the feeding pipe 6 and the hopper 2 is provided with a sealing ring 4; The adjustment handle 1 of the feeding pipe 6; the feeding pipe 6 is composed of a circular steel pipe 6-1 and an arc-shaped hose 6-2; the end of the arc-shaped hose 6-2 is located at the first discharge barrel 7 or in the second discharge barrel 8, so that the material in the curved hose 6-2 enters the first discharge barrel 7 or the second discharge barrel 8 at a tangent; the first discharge barrel 7 or the second discharge barrel A notch 7-1 for placing an arc-shaped hose 6-2 is provided on the side wal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com