Denoiser for milling tubes

A noise reducer and noise reduction technology, applied in the direction of instruments, sounding equipment, milling machine equipment, etc., can solve problems such as affecting the work of others, affecting the health of employees, polluting the environment, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

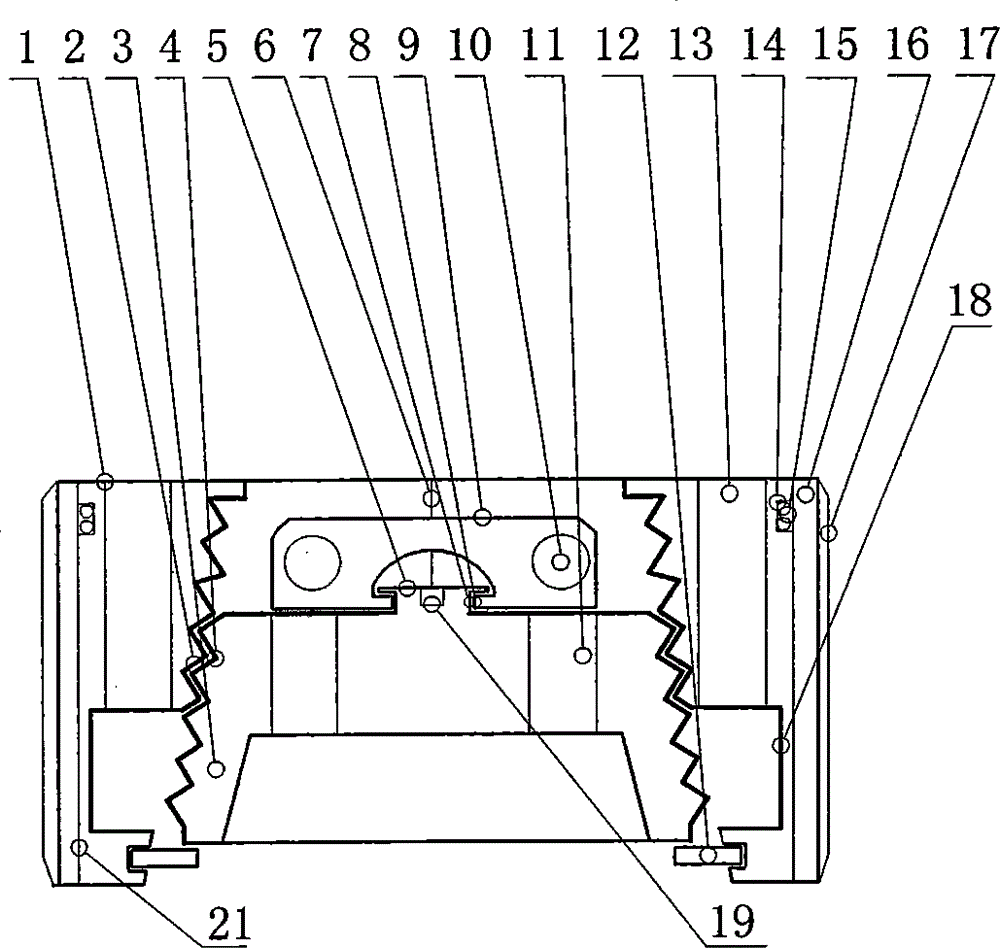

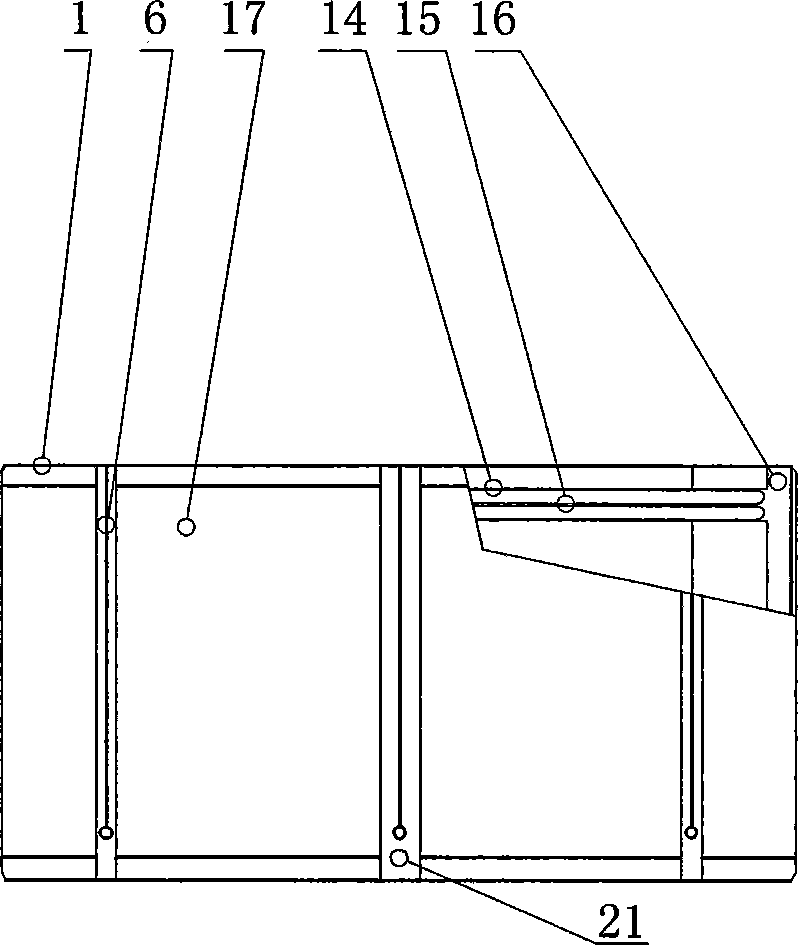

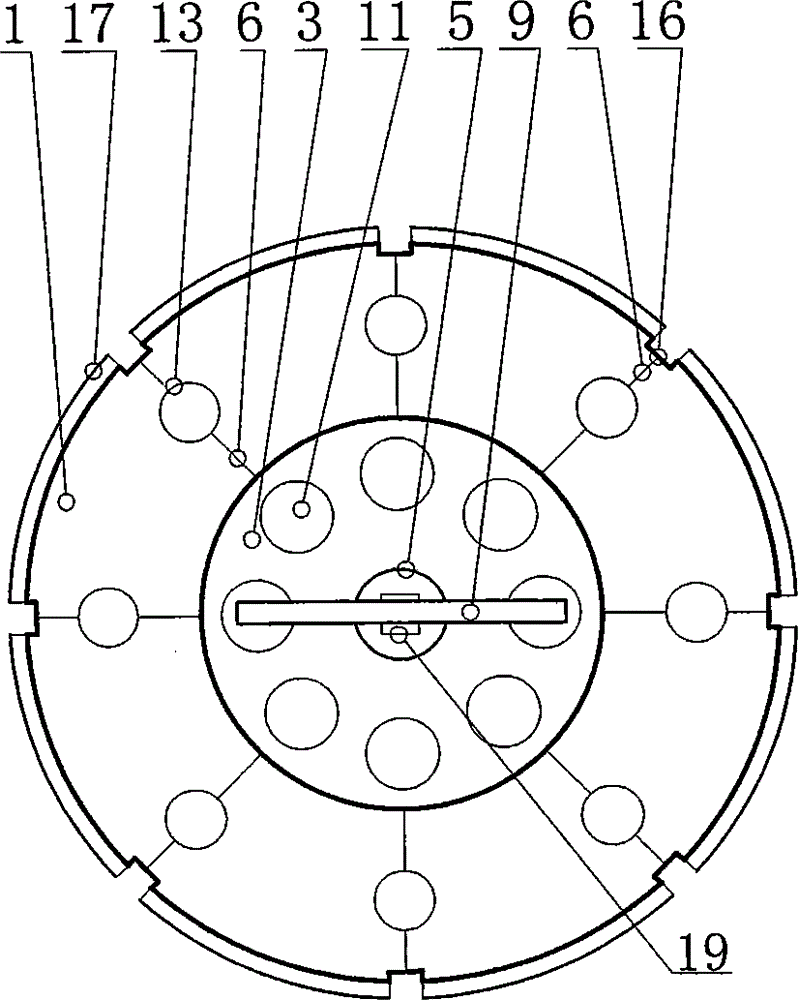

[0013] The specific implementation manners in this application will be further described below in conjunction with the accompanying drawings.

[0014] figure 1 , figure 2 , image 3 , Figure 4 Among them, including expansion block 1, internal thread 2, plug core 3, external thread 4, screw cap 5, expansion joint 6, key hole 7, key pin 8, fall key 9, knob hole 10, return channel 11, plug core Circlip 12, flow channel 13, annular channel 14, annular spring 15, die seam 16, silicone skin 17, expansion tube wall 18, internal rotation hole 19, pipe fitting 20, expansion tube 21, etc.

[0015] According to the present application, a noise reducer for pipe milling includes a noise reduction plug mechanism, a plug core mechanism, and a knob mechanism.

[0016] The noise reduction plug mechanism is set in a cylindrical shape, including an expansion tube 21, an expansion block 1, an expansion joint 6, an internal thread 2, a flow channel 13, an annular channel 14, an annular sprin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com