Large-upsetting-force large-inertia force closure steel aluminum friction welding machine overall structure

A large inertia force, friction welding machine technology, applied in welding equipment, welding equipment, non-electric welding equipment and other directions, can solve the problems of difficult to control welding accuracy, high machine tool height, large energy consumption, etc., to reduce the size of the base, increase the Clamping length, the effect of preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

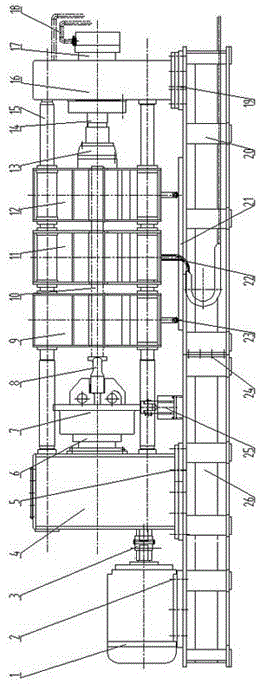

[0009] Such as figure 1 As shown, the present invention is the overall structure of a closed steel-aluminum friction welding machine with large upsetting force and large inertia force. The first machine base 26 and the second machine base 20 are connected together by the machine base connecting screw group 24, and the variable frequency motor 1 is formed by the motor base. The fixing screw group 2 is fixed on the first machine tool base 26, the input shaft on the spindle box 4 is connected with the motor shaft by the electromagnetic clutch 3, the output shaft of the spindle box is the main shaft, and the steel claw hydraulic clamp 7 is connected, and the steel claw hydraulic clamp 7 can complete the steel clamp. Clamping of the claws; the first aluminum guide rod displacement fixture 9, the second aluminum guide rod displacement fixture 11, and the third aluminum guide rod displacement fixture 12 with the same structure are respectively supported and connected by the pre-stretc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com