Rolling processing method of sealing tooth lobe of exhaust connection pipe

A technology of exhaust pipe and processing method, which is applied in the field of sealing structure processing, can solve the problems of heavy workload and insufficient stability of tooth flaps, etc., and achieve the effects of facilitating processing, reducing processing allowance, and simplifying operation procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

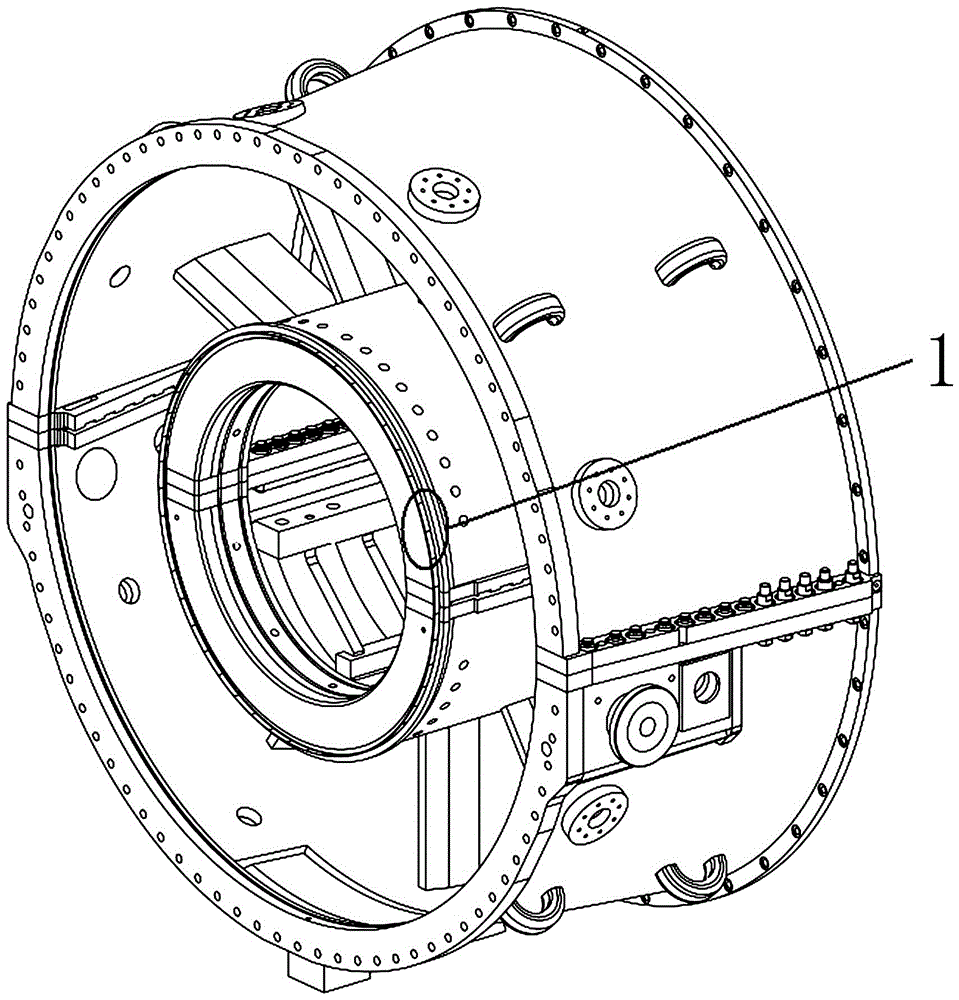

[0028] Such as Figure 1-7 Among them, a rolling processing method of exhaust joint sealing tooth lobe, comprising the following steps:

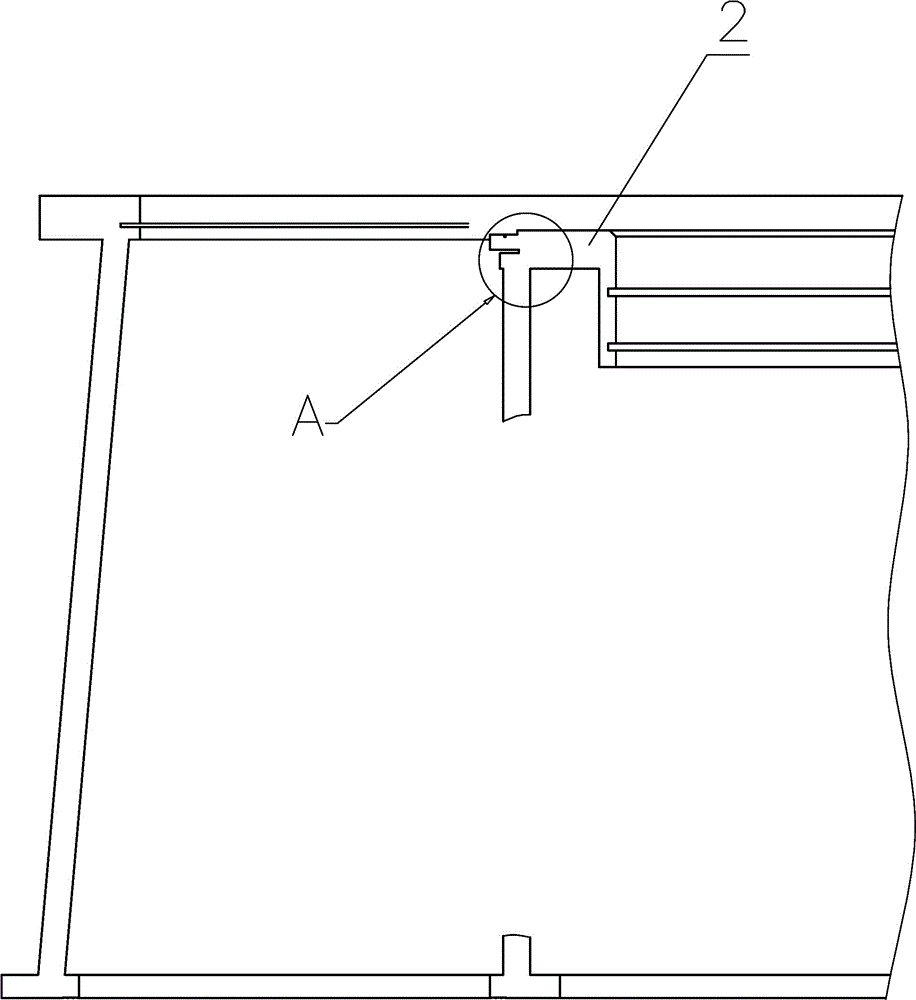

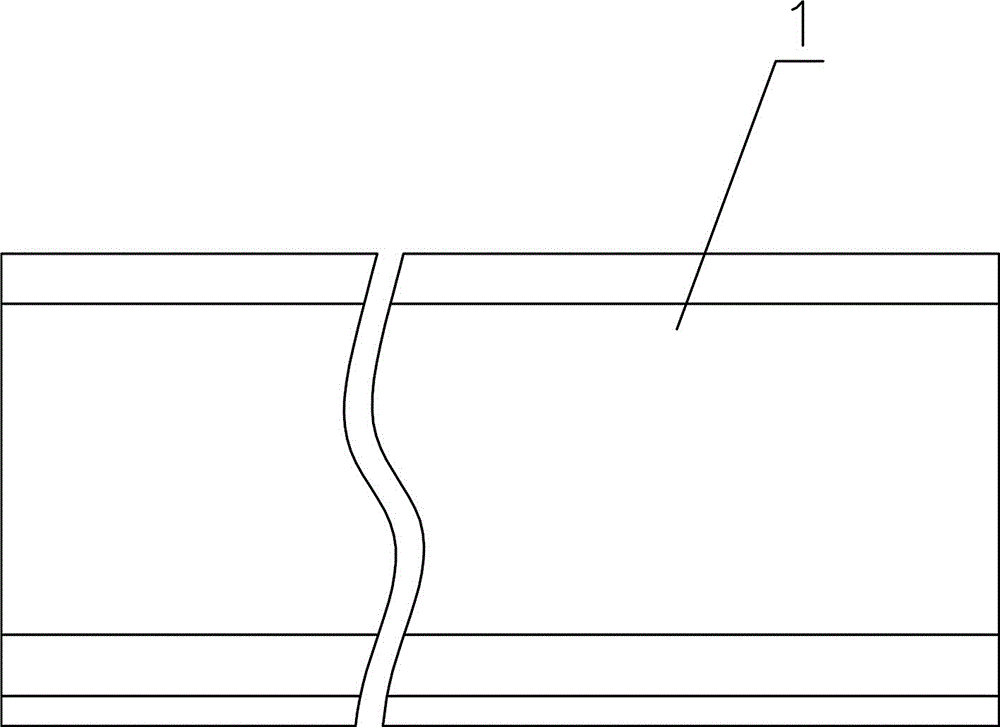

[0029] 1. Process the flaky tooth petal 1; the processed tooth petal 1 is as figure 1 As shown in , the processed tooth lobe 1 has a length of 115 mm, and an arc-shaped limiting groove 12 is processed on it, so that the installation groove 21 can be tightly combined with the tooth lobe 1 after deformation. In a preferred solution, pre-cutting is performed on the inner side of the tooth lobe 1, and a machining allowance of 0.1-0.3 mm is reserved. In this example, the reserved processing allowance is 0.2mm, and a step is formed inside the tooth lobe 1.

[0030] After pre-processing, the tooth flap becomes thinner, which makes it easier to bend the tooth flap into a circular arc, and the inner hole with higher roundness can be obtained after the tooth flap is assembled. Moreover, the machining allowance is reduced, and after the tooth flap i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com